180R9346 | AQ240486503020en-001702 | 49© Danfoss | 2023.03

Operation guide Installation, Operation and Maintenance APP 53-92 pumps

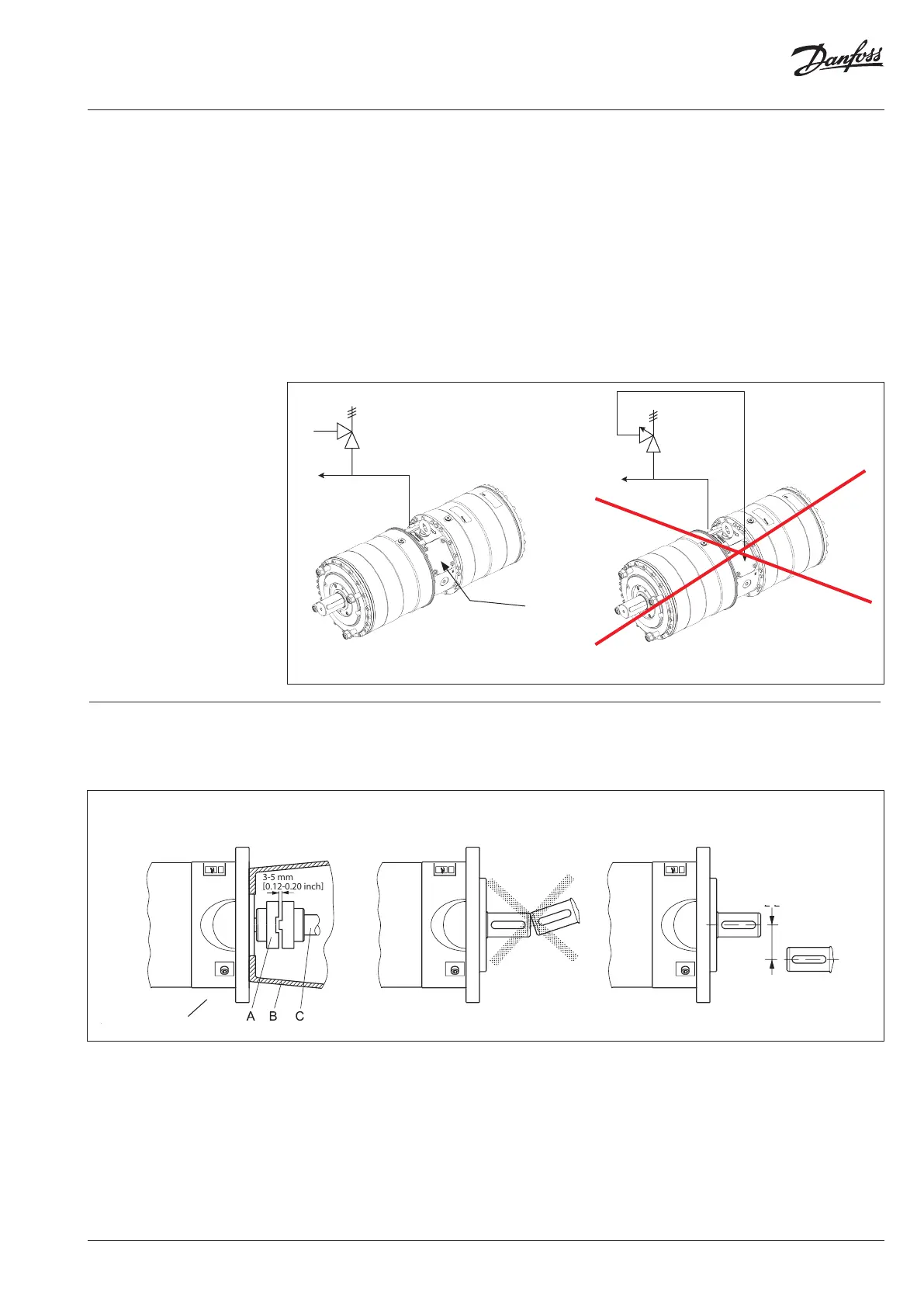

3.4 Direction of rotation

Is indicated by an arrow engraved in the ange

of the pump.

3.5 Orientation

APP 53-92 can be mounted/orientated in steps of

45 degrees. Please see Data sheet 521B1340.

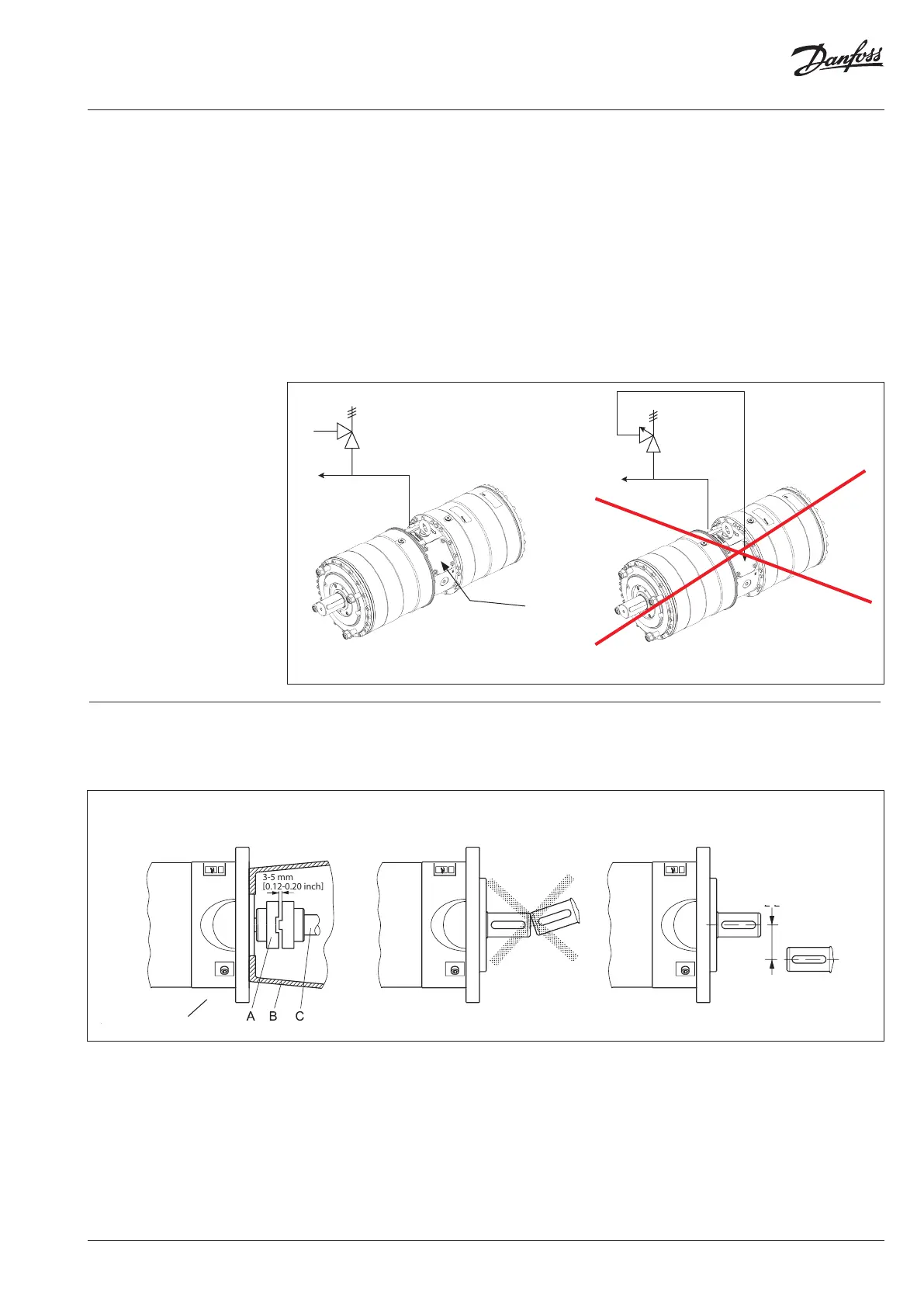

4. Building up the

pump unit with jaw

coupling

D

A: Elastic coupling

B: Bell housing

C: Motor shaft

D: Pump ange

4.1 Mounting

1. Mount the coupling ush with the pump

shaft end or maximum 1 mm oset from

the pump shaft end. Ensure an air gap

between coupling parts of 3-5 mm (0.12-0.2

inch).

2. Mount the bell housing on pump. Secure

nuts with the right torque.

3. Measure the longest distance “A” from top

of bell housing to the button of coupling

claw.

4. Mount the coupling on motor shaft. Ensure

the coupling and motor ange are not in

contact with each other.

5. Measure from motor ange to the top of

the coupling. That measurement “B” shall

be 3-5 mm (0.12-0.2 inch) shorter than the

measurement “A”.

(“A” and “B” can be found on the next

page).

The opening characteristics of the valve must not

result in peak pressures higher than 100 barg

(1450 psig).

The valve should be placed as close to the pump

as possible.

We recommend to install exible soft hoses both

in the inlet and outlet lines.

3.6 Protection from too high pressures

The pump should be protected against too high

pressure by means of a safety valve or a pressure

relief valve.

The valve outlet must not be connected directly to the pump suction line.

It must be connected directly to the drain.

Outlet

Outlet Inlet

IMPORTANT

When using jaw coupling it is critiacal

that the recommended measure-

ments are kept.

max. 0.25 mm

max. 0.01 inch

Inlet

Loading...

Loading...