CAUTION

Remote filter heads without bypass and poor plumbing design can encounter excessive pressure drops

that can lead to charge pump damage in addition to contaminants being forced through the filter media

and into the transmission loop.

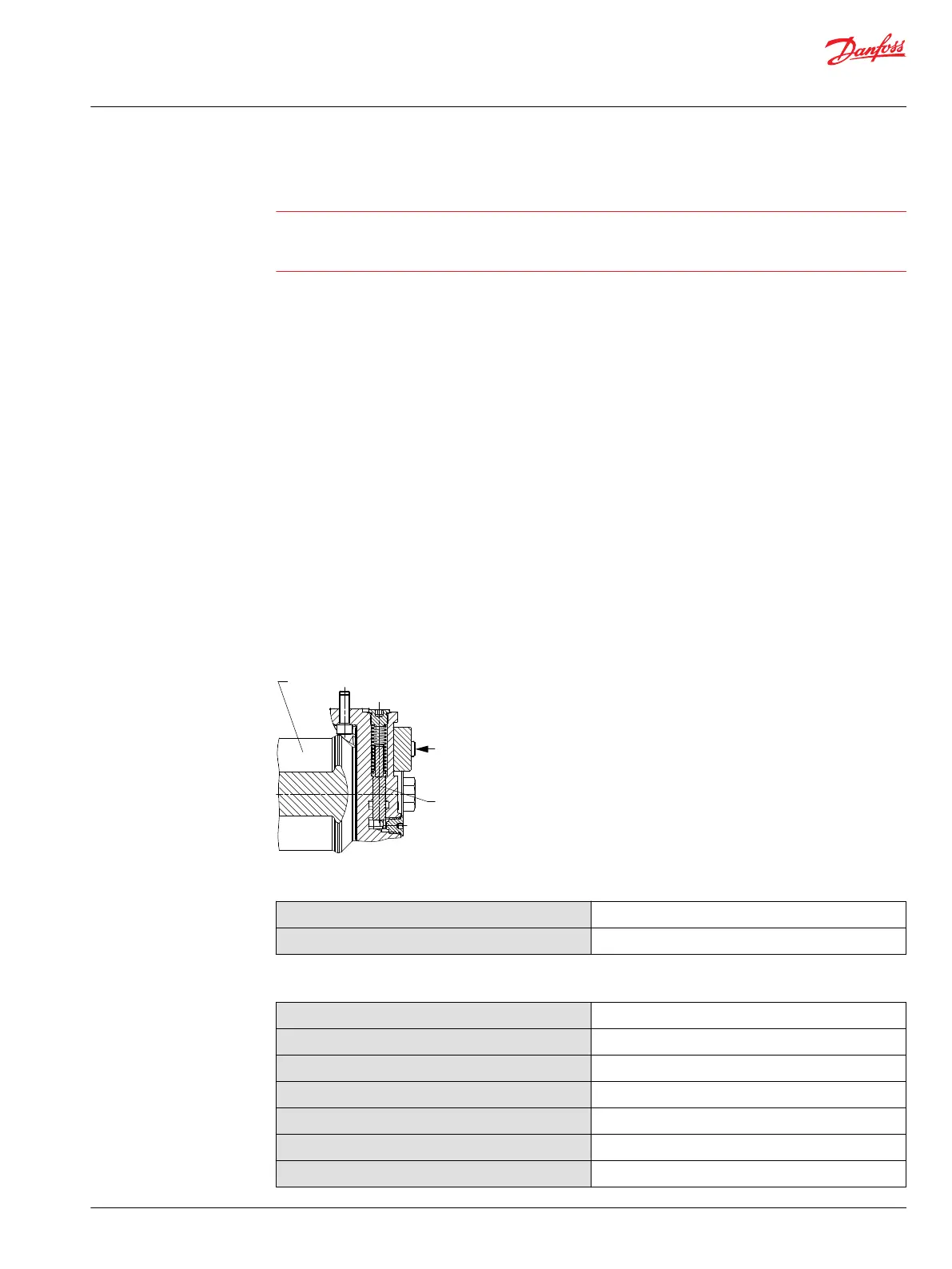

Integral charge pressure filtration

The H1 integral pressure filter head is designed with a filter bypass valve and noncontacting bypass

sensor. The pressure differential acting on the filter element also acts on a spring biased bypass spool.

This spool is designed with a magnetic area. When a certain spool position is reached, the magnet closes

a switch in the bypass sensor which allows R2 to be in parallel with R1. This occurs without any

mechanical contact between the spool and the bypass sensor.

The position of the bypass spool is indicated by the change in the measured sensor resistance. The

change in resistance occurs when R2 is switched in and out of the circuit.

When the filter is not being bypassed, the nominal measured resistance is 510 Ω. When the switch is

closed, the nominal measured resistance is 122 Ω.

The bypass spool is designed so the bypass sensor switch will be closed before oil bypasses the filter

element. This gives the machine operator an indication that the filter is very close to bypassing and a

filter replacement is required.

For cold start conditions, it is typical that the filter may bypass for a short amount of time while the oil is

warming up. At normal operating oil temperatures, a system that does not yet need a filter replacement

will operate in the non-bypass mode. The addition of an oil temperature sensor and additional control

logic, is recommended to properly determine if a filter replacement is required.

Integral filter head with filter bypass sensors

Bypass spool

Filter

bypass sensor

Filter

element

P003 359E

Technical data, pressures

Filter bypass sensor switch closure ∆p

3.7 - 5.1 bar [54 - 74 psi]

Bypass valve ∆p

5.6 ± 0.9 bar [80 ± 13 psi]

Technical data, electric

Max. voltage

48 V

Max. power

0.6 W

Switch open

510 Ω

Switch closed

122 Ω

Resistor tolerance

1 %

Temperature range

-20 ÷ +100 °C [-4 ÷ +212 °F]

IP Rating (IEC 60 529) + DIN 40 050

IP 69K part 9 with mating connector

Basic Information

H1 Axial Piston Pumps, Single and Tandem

System design parameters

©

Danfoss | April 2017 11062168 | BC00000057en-US0602 | 27

Loading...

Loading...