Filtration

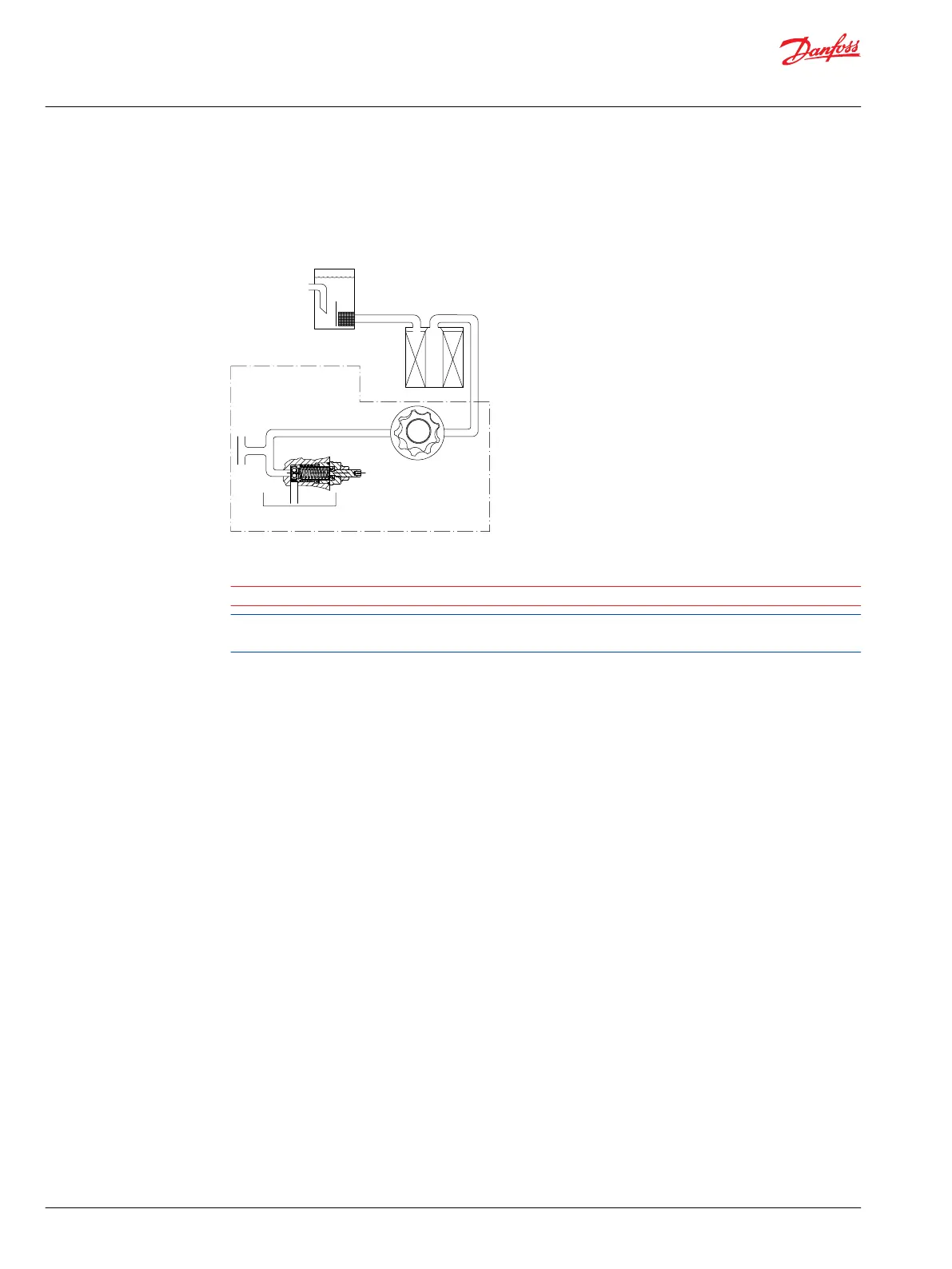

The suction filter is placed in the circuit between the reservoir and the inlet to the charge pump as shown

in the accompanying illustration.

Suction filtration

P003 471E

Reservoir

Strainer

Filter

Charge

pump

Charge

relief

valve

to pump case

to low pressure

side of loop

and servo control

Warning

Clogged filters can cause cavitation, which damages the charge pump.

We recommend a filter bypass with a filter bypass sensor to prevent damage due to blocked suction

filters.

Charge pressure filtration (full charge pump flow)

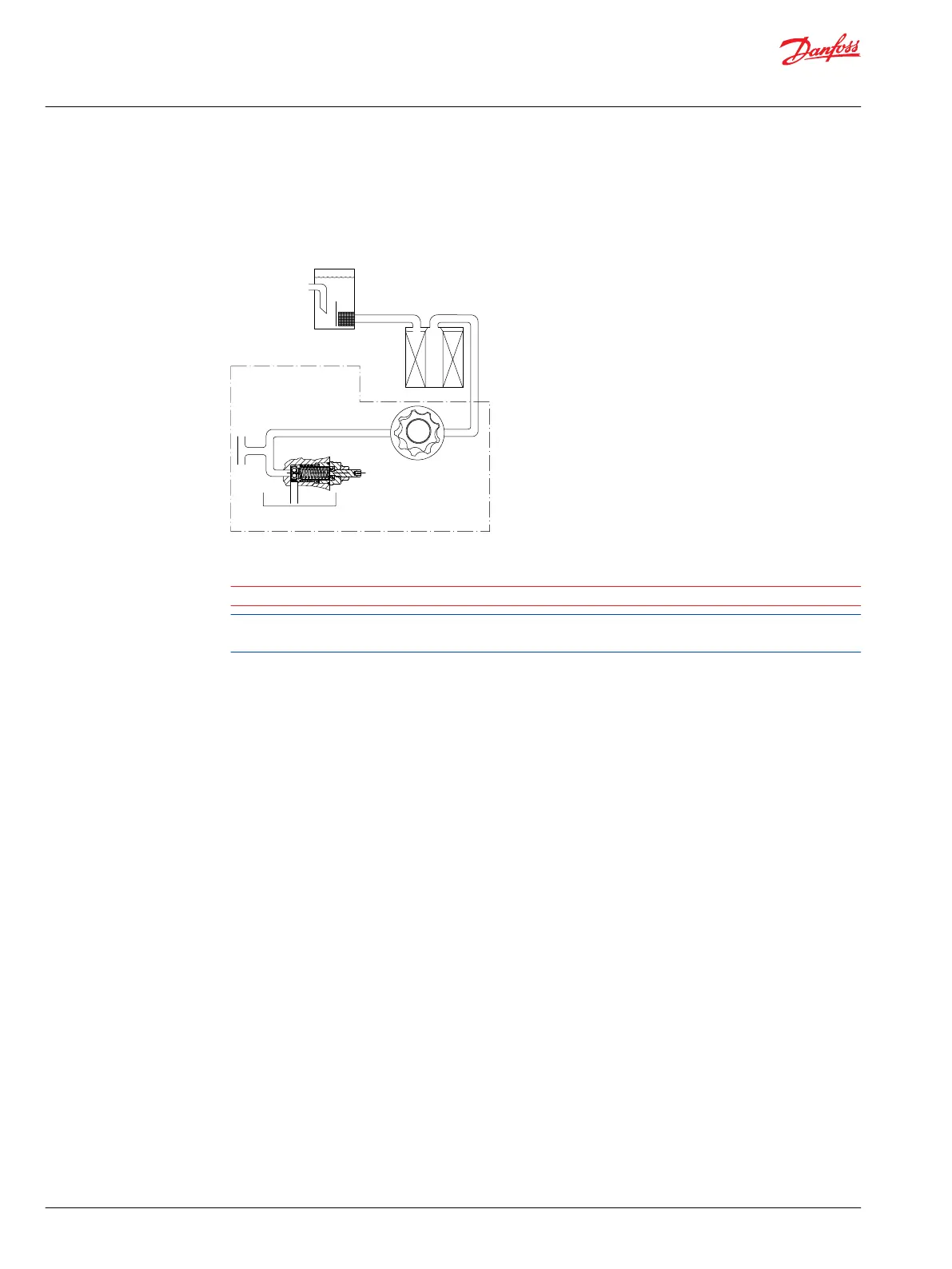

For most H1 pumps exist two types of pressure filtration:

•

remote pressure filtration (filter remotely mounted on vehicle)

•

integral pressure filtration (filter mounted to the endcap)

Verify option availability in the size specific technical information. In either case the filtration circuit is the

same with the filter element situated in the circuit downstream the charge pump and upstream of the

charge relief valve such that full charge flow is continuously filtered, as shown in the accompanying

illustrations.

Charge pressure filtration can mitigate high inlet vacuum in cold start-ups and provides fluid filtration

immediately prior to entrance to the loop and the control system. Pressure filtration provides a higher

level of filtering efficiency than suction filtration.

Filters used in charge pressure filtration circuits must be rated to at least 35 bar [508 psi] pressure.

A 100 – 125 µm screen located in the reservoir or in the charge inlet line is recommended when using

charge pressure filtration.

A filter bypass valve is necessary to prevent filter damage and to avoid contaminants from being forced

through the filter media by high pressure differentials across the filter.

In the event of high pressure drop associated with a blocked filter or cold start-up conditions, fluid will

bypass the filter. Working with an open bypass should be avoided.

Remote charge pressure filtration

Ports at the endcap are available to allow for the charge filter to be located conveniently for easy service

and replacement. Care should be taken to minimize the hydraulic pressure drops associated with long

connecting lines, small diameter hoses, or restrictive port adaptors at the filter head or endcap. Ensure

the normal operating pressure drop across the remote filtration in and out ports is sufficiently below the

crack pressure setting of the recommended filter bypass valve.

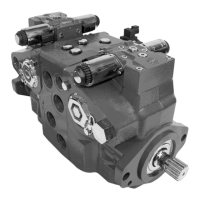

Basic Information

H1 Axial Piston Pumps, Single and Tandem

System design parameters

26 |

©

Danfoss | April 2017 11062168 | BC00000057en-US0602

Loading...

Loading...