23

INSTALLATION AND SERVICE

System cleanliness

System contamination is one of the

main factors that a ects equipment

reliability and compressor service life.

Therefore it is important to take care

of the system cleanliness when as-

sembling a refrigeration system. Dur-

ing the manufacturing process, circuit

contamination can be caused by:

z

Brazing and welding oxides,

z

Filings and particles from removing

burrs from pipe-work,

z

Brazing ux,

z

Moisture and air.

Only use clean and dehydrated,

refrigeration-grade copper tubes and

silver alloy brazing material. Clean all

parts before brazing and always purge

nitrogen or CO

2

through the pipes

during brazing to prevent oxidation.

If ux is used, take every precaution

to prevent the leakage of ux into

the piping. The use of ux core or

ux coated braze wire or rod instead

of brush applied paste ux is strongly

recommended. Do not drill holes

(e.g. for schrader valves) in parts

of the installation that are already

completed, when lings and burrs

cannot be removed. Carefully follow

the instructions below regarding

brazing, mounting, leak detection,

pressure test and moisture removal.

All installation and service work shall

only be done by quali ed personnel

respecting all procedures and using

tools (charging systems, tubes, vacuum

pumps, etc.) dedicated for R404A and

R507A.

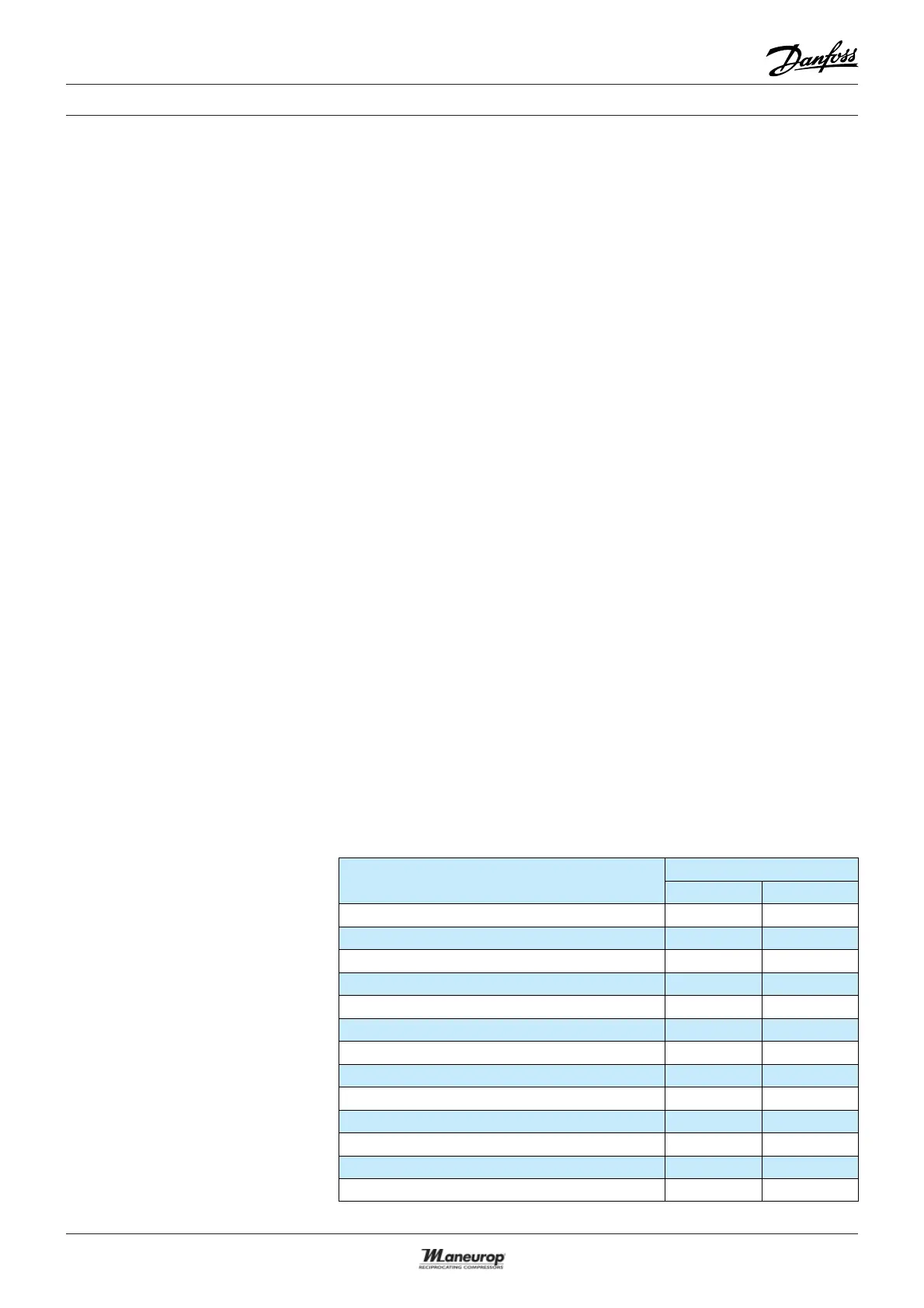

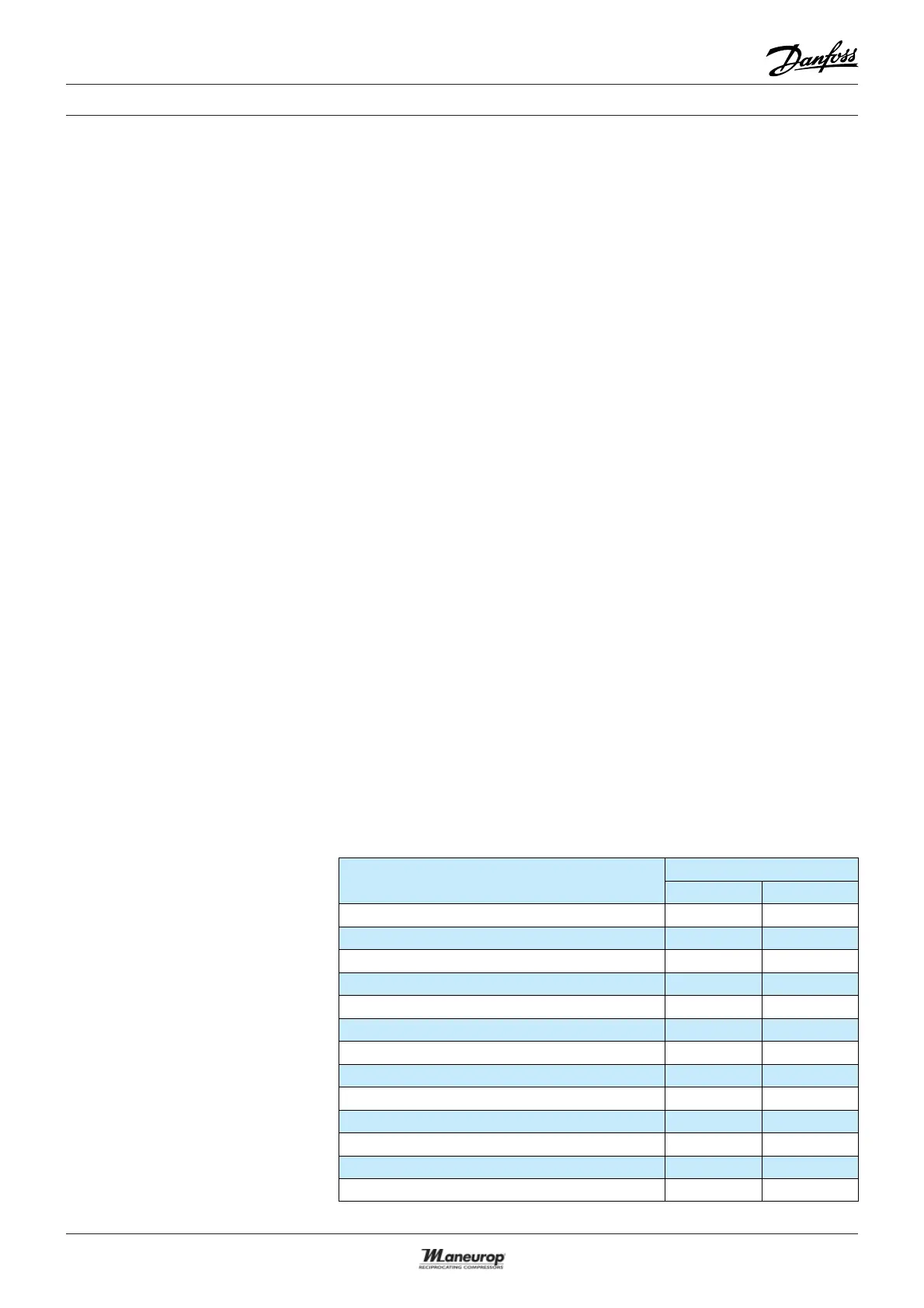

Compressor handling,

mounting and connection

Component

Torque (Nm)

Min. Max.

Rotolock suction valve, NTZ048 - NTZ068 80 100

Rotolock suction valve, NTZ096 - NTZ271 100 120

Rotolock discharge valve, NTZ048 – NTZ068 70 90

Rotolock discharge valve, NTZ096 - NTZ271 80 100

Electrical T-block screws HN°10-32 UNF x 9.5 - 3

Earth screw - 3

Oil sight glass (with black chloroprene gasket) 40 45

3/8” are oil equalisation nut 45 50

Schrader nut 11.3 17

Schrader valve (internal) 0.4 0.8

Mounting grommet bolt, NTZ048 – NTZ136 12 18

Mounting grommet bolt, NTZ215 - NTZ271 40 60

Belt crankcase heater - 4

Compressor handling Maneurop® NTZ compressors must be

handled with care and all handling pro-

cedures must be performed smoothly

and gently. Each NTZ has been tted

with one lift ring which shall always be

used to lift the compressor. Once the

compressor is installed, the lift ring

shall never be used to lift the complete

installation.

Always use the proper tools for trans-

porting the compressor. Keep the

compressor in an upright position dur-

ing all handling tasks (manipulating,

transport, storage). The angle o the

vertical must not exceed 15 degrees.

Compressor mounting The compressor must be mounted

onto a horizontal surface with a maxi-

mum slope of 3 degrees. Always use

the rubber mounting grommets that

are shipped with the compressor.

Mounting torques are listed in the be-

low table.

Loading...

Loading...