© Danfoss A/S (RA Marketing/MWA), Nov. 08 RS8FE102, 080R9278 11

OPTYMA

TM

Control three-phase Operation and Maintenance Guide

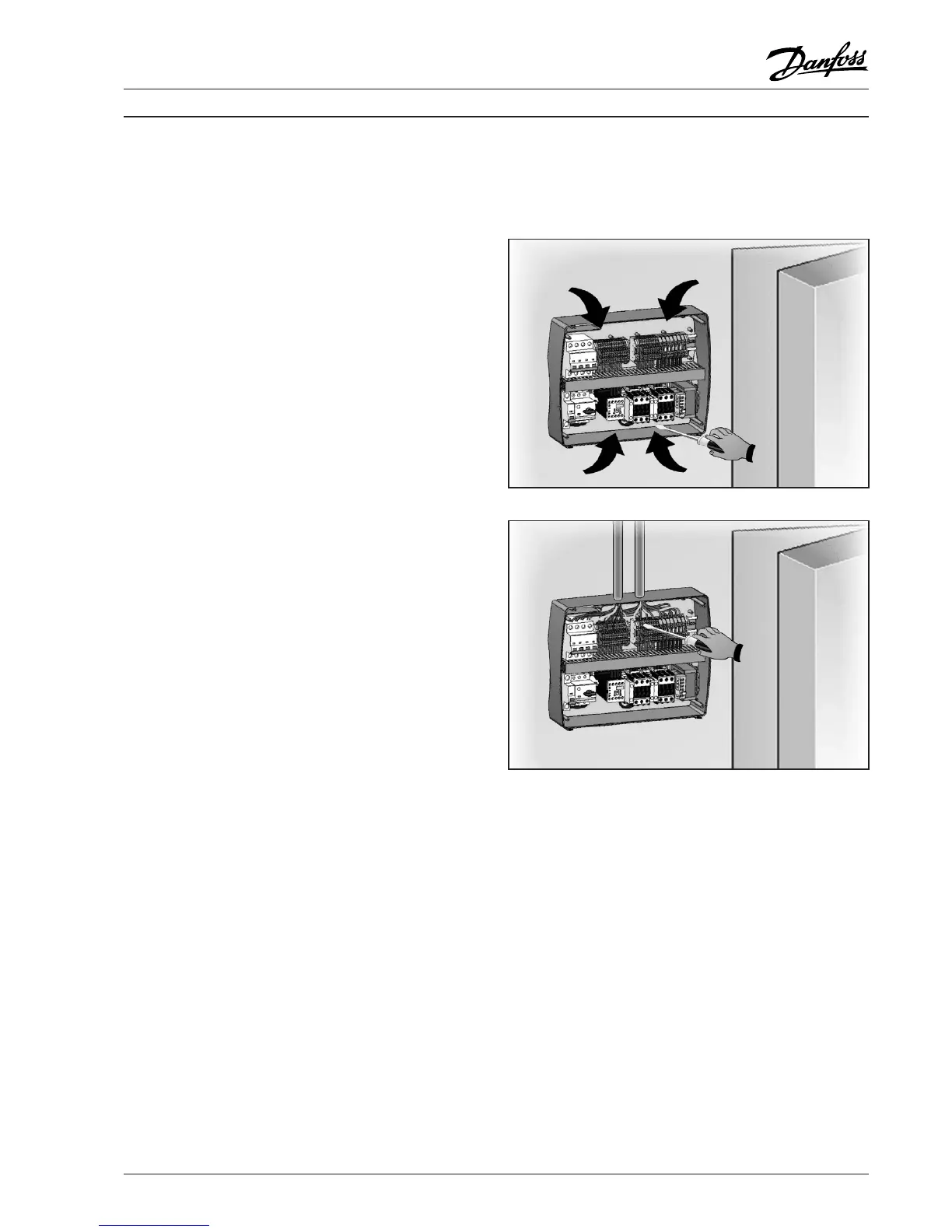

10.

Using the holes made in point 9 above, screw the

back panel to the wall using 4 screws of a suitable

length for the wall thickness. Fit a rubber washer

(supplied) between each screw and the housing

back panel.

Installing the unit

(continued)

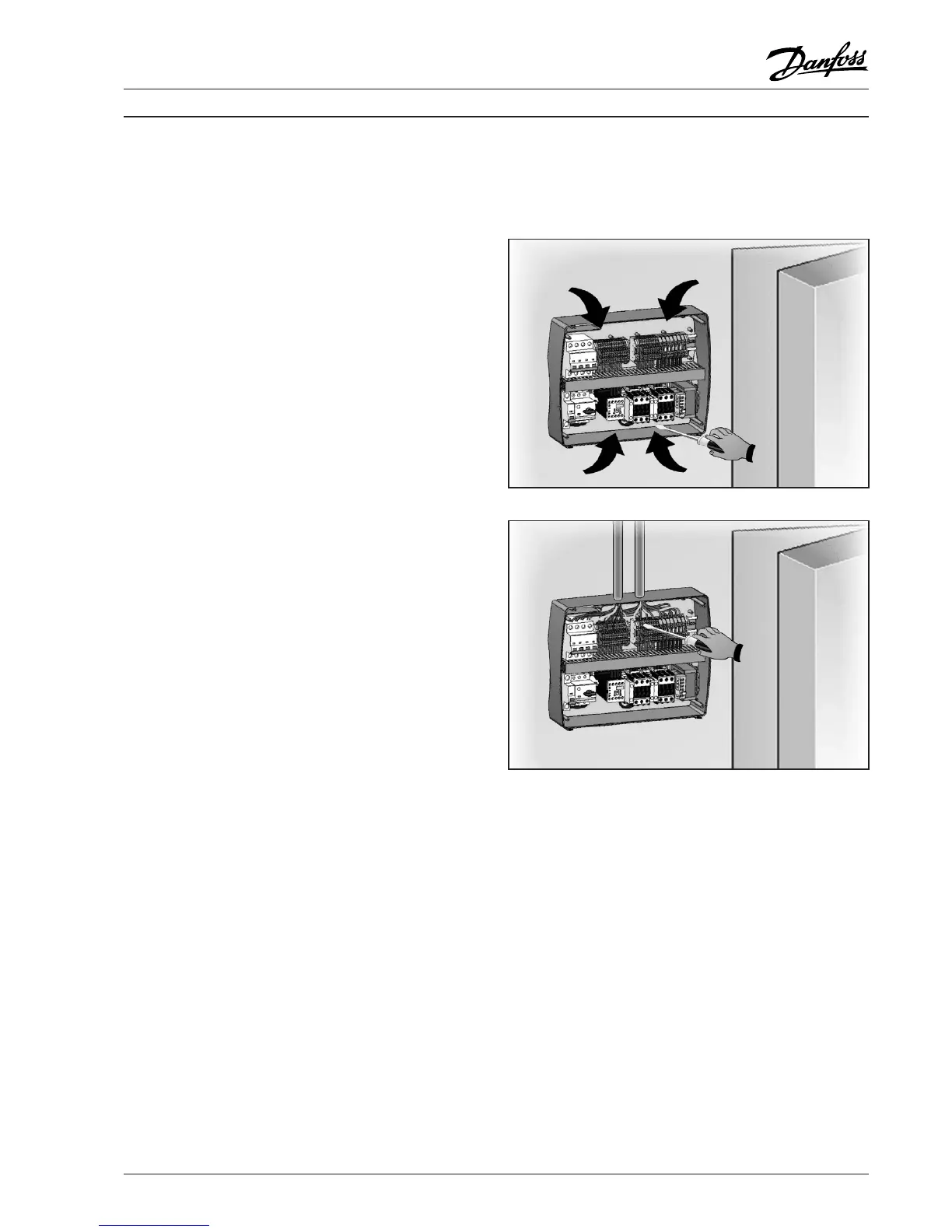

11.

Now do the electrical wiring as shown below.

Electrical wirings

• For the electrical wiring please refer to the wiring

instruction and technical characteristics of the

controller being installed.

• The controller power supply must be on a

dedicated line, and must be equipped with a

suitable device to protect against indirect contacts

upstream of the line (differential interrupter).

• Do not route power supply wiring and signal

wiring (probes/sensors and digital inputs)

in the same raceways or ducts.

• Do not use multi-polar cables which have wires

connected to inductive/power loads and signalling

wires (e.g. probes/sensors and digital inputs).

• Minimise the length of connector wires so that

wiring does not twist into a spiral shape, as this

could have a detrimental effect on the elec-

tronics.

• If a probe/sensor extension is required, the wires

must have a diameter of at least 1 mm

2

.

• All wiring must be of a diameter suitable for the

relevant power levels. The degree of insulation

must be compatible with the applied voltages.

Preferably use cables with flame-retardant

insulation and a low smoke emission where fire

regulations apply.

• It is essential to connect the clamp marked PE

to the earth of the supply system.

If necessary, please check the eectiveness of

the earthing system.

• Do not connect to the PE clamp conductors

any dierent than the external protection.

Loading...

Loading...