24 RS8FE102, 080R9278 © Danfoss A/S (RA Marketing/MWA), Nov. 08

OPTYMA

TM

Control three-phase Operation and Maintenance Guide

In the event of any anomalies, the OPTYMA

TM

Control

warns the operator by displaying alarm codes and

sounding the warning buzzer inside the control

Alarm codes

panel. If an alarm is tripped, the display will show one

of the following messages:

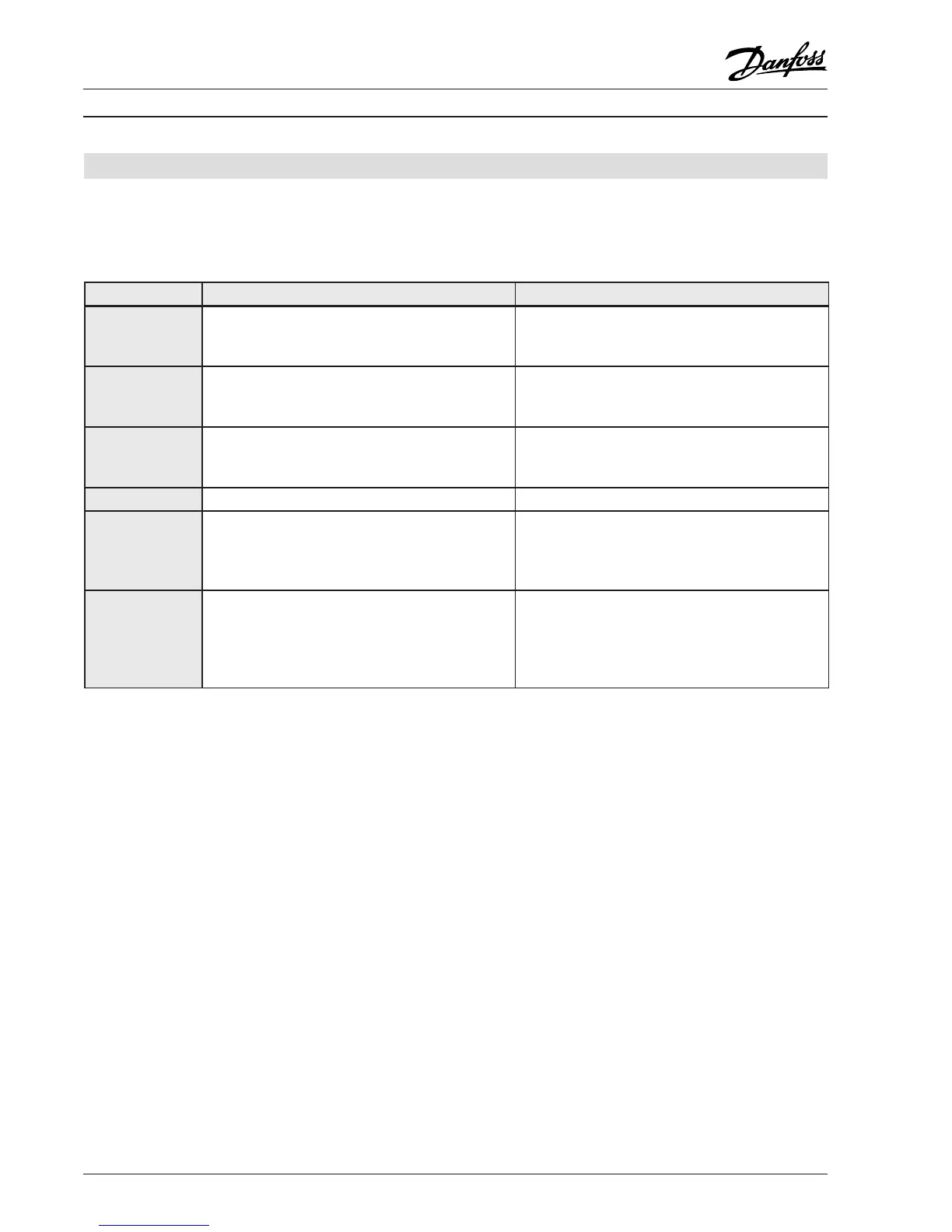

Alarm code Possible cause Solution

E0 Cold room temperature sensor not working

properly

• Check that the cold room temperature

sensor is working properly.

• If the problem persists, replace the sensor.

E1 Defrost sensor not working properly

(In this case defrosts will last time d3)

• Check that the defrost sensor is working

properly.

• If the problem persists, replace the sensor.

E2 Eeprom alarm

An EEPROM memory alarm has been detected

(All outputs except the alarm are deactivated)

• Switch unit o and back on again.

E8 Man-in-cold-room alarm • Reset the alarm input inside the cold room

Ec Compressor protection tripped (e.g. thermal

protection or max. pressure switch)

(All outputs except the alarm– where

applicable – are deactivated)

• Check that compressor is working properly.

• Check compressor absorption.

• If the problem persists, contact the

technical assistance service.

Temperature

shown on

display is

flashing

Minimum or maximum temperature alarm.

The temperature inside the cold room has

exceeded the min. or max. temperature

alarm setting (see variables A1 and A2, user

programming level)

• Check that the compressor is working

properly.

• Sensor not reading temperature correctly or

compressor start/stop control not working.

Loading...

Loading...