1 Introduction

1.1 Purpose of the Manual

This manual provides information on how to design and

implement center winder control and positioning control

applications with FC 360 frequency converters. It does not

cover general design, installation and commissioning of

the frequency converter.

VLT

®

is a registered trademark.

Prerequisites

The manual is intended for use by qualified personnel who

are familiar with the functions of VLT

®

AutomationDrive FC

360 and have hands-on experience with installing and

commissioning FC 360 frequency converters. The

frequency converter should be installed and commissioned

according to the FC 360 Quick Guide. Users of this manual

should have the Quick Guide at hand for reference.

1.2 Additional Resources

Additional resources are available to understand frequency

converter functions and programming.

•

VLT

®

AutomationDrive FC 360 Quick Guide,

provides information required to install and

commission the frequency converter.

•

VLT

®

AutomationDrive FC 360 Design Guide,

provides detailed information about the design

and applications of the frequency converter.

•

VLT

®

AutomationDrive FC 360 Programming Guide,

provides information on how to programme and

includes complete parameter descriptions.

Contact the local Danfoss supplier for the printed

documentation.

1.3

Document and Software Version

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding software

version.

In the frequency converter, read the software version in

15-43 Software Version.

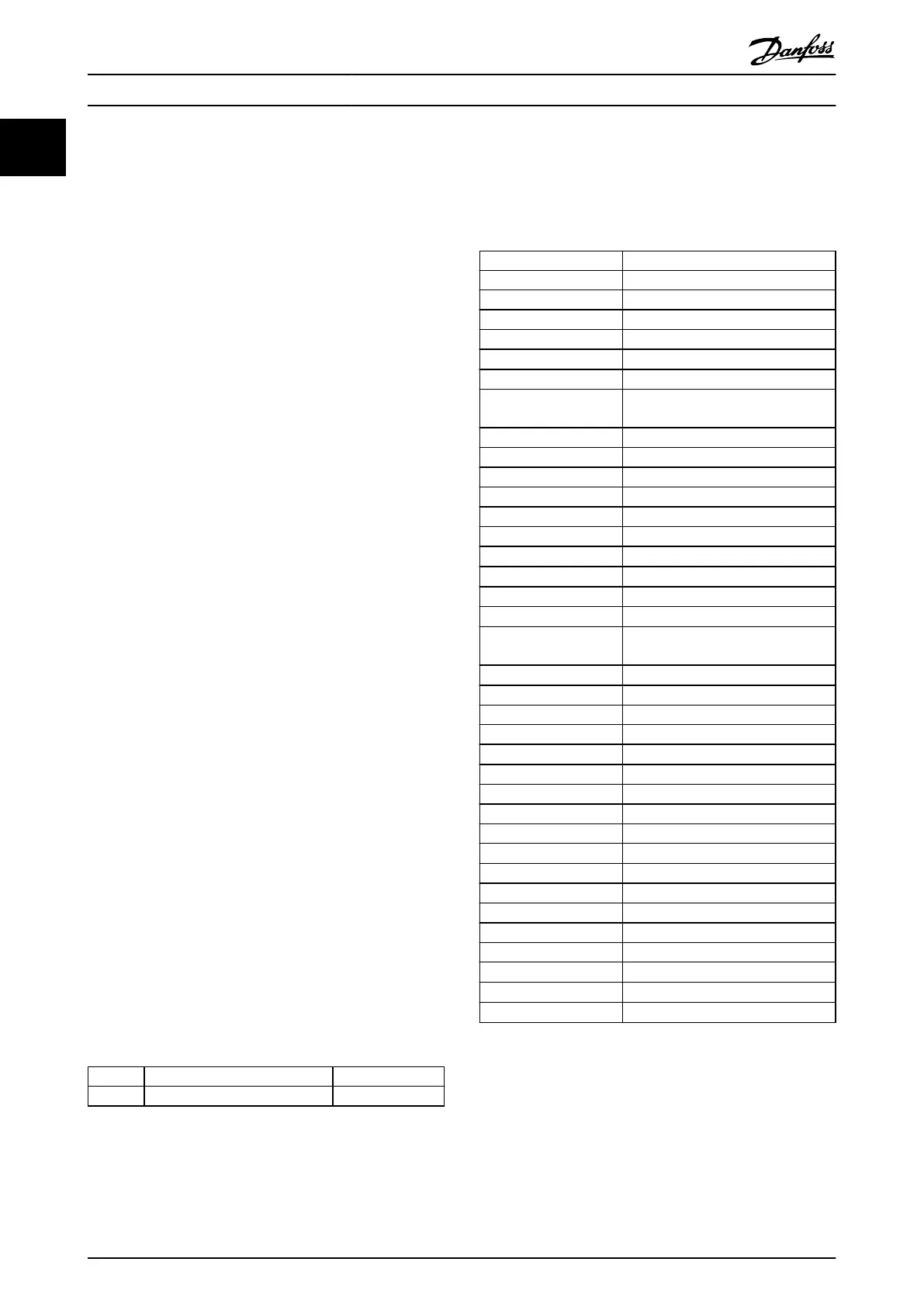

Version Remarks Software version

MG06E1 First version of the document. 1.4x

Table 1.1 Document and Software Version

1.4

Abbreviations and Conventions

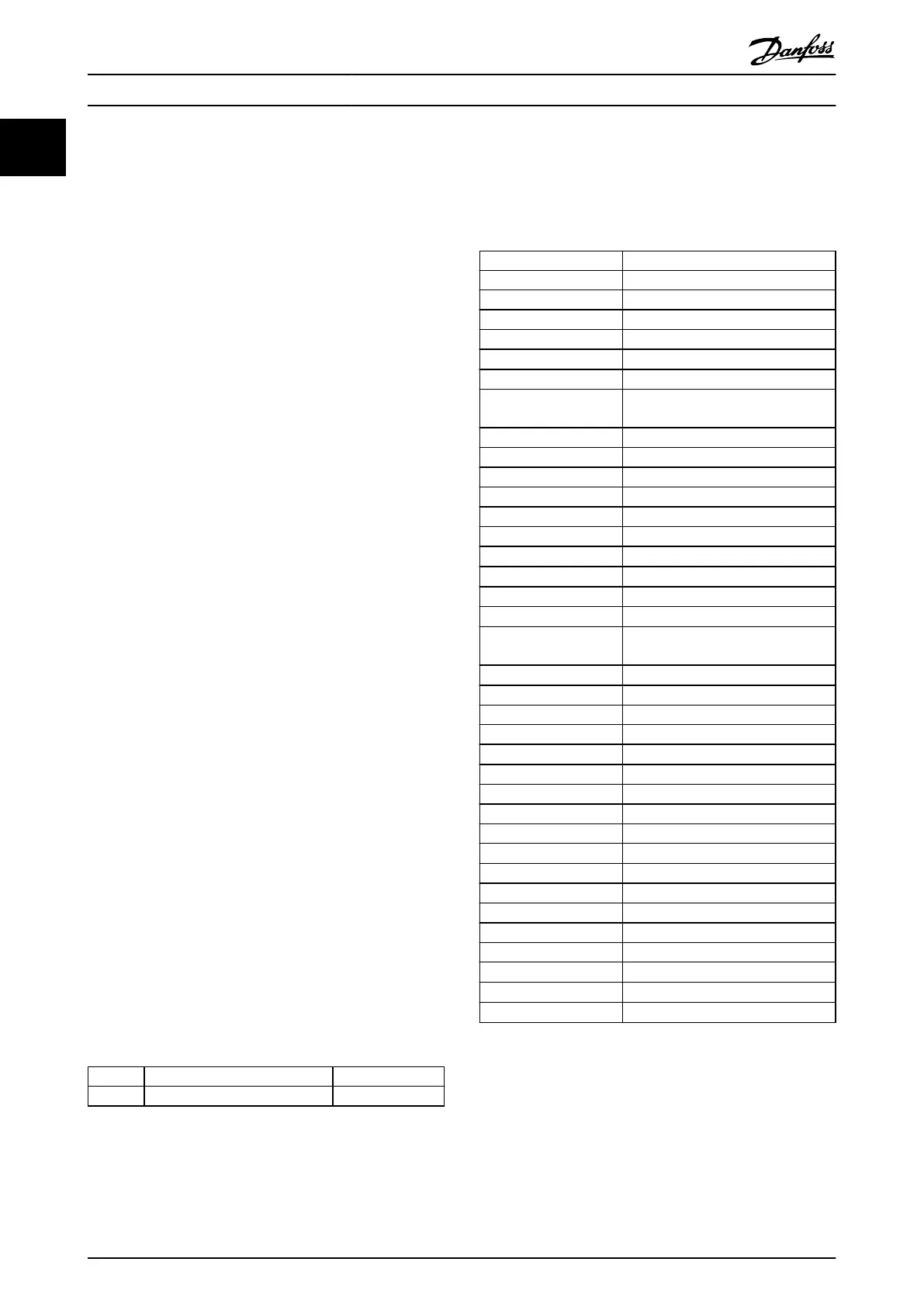

AC Alternating current

AEO Automatic energy optimisation

ACP Application control processor

AWG American wire gauge

AMA Automatic motor adaptation

°C

Degrees Celsius

DC Direct current

EEPROM

Electrically erasable programmable

read-only memory

EMC Electromagnetic compatibility

EMI Electromagnetic interference

ETR Electronic thermal relay

f

M,N

Nominal motor frequency

FC Frequency converter

IP Ingress protection

I

LIM

Current limit

I

INV

Rated inverter output current

I

M,N

Nominal motor current

I

VLT,MAX

Maximum output current

I

VLT,N

Rated output current supplied by the

frequency converter

L

d

d-axis inductance

LCP Local control panel

MCP Motor control processor

N.A. Not applicable

P

M,N

Nominal motor power

PCB Printed circuit board

PE Protective earth

PELV Protective extra low voltage

PWM Pulse width modulated

R

s

Stator resistance

Regen Regenerative terminals

RPM Revolutions per minute

RFI Radio frequency interference

SCR Silicon controlled rectifier

SMPS Switch mode power supply

T

LIM

Torque limit

U

M,N

Nominal motor voltage

X

h

Main reactance

Table 1.2 Abbreviations

Conventions

•

Numbered lists indicate procedures.

•

Bullet lists indicate other information.

•

Italicised text indicates

Introduction

VLT

®

AutomationDrive FC 360

2 Danfoss A/S © 11/2014 All rights reserved. MG06E102

1

1

Loading...

Loading...