1. Use a clamp from the accessory bag

to connect screen to frequency con-

verter decoupling plate for control

cables.

See section entitled

Earthing of Screened/

Armoured Control Cables

for the correct ter-

mination of control cables.

Illustration 4.29: Control cable clamp.

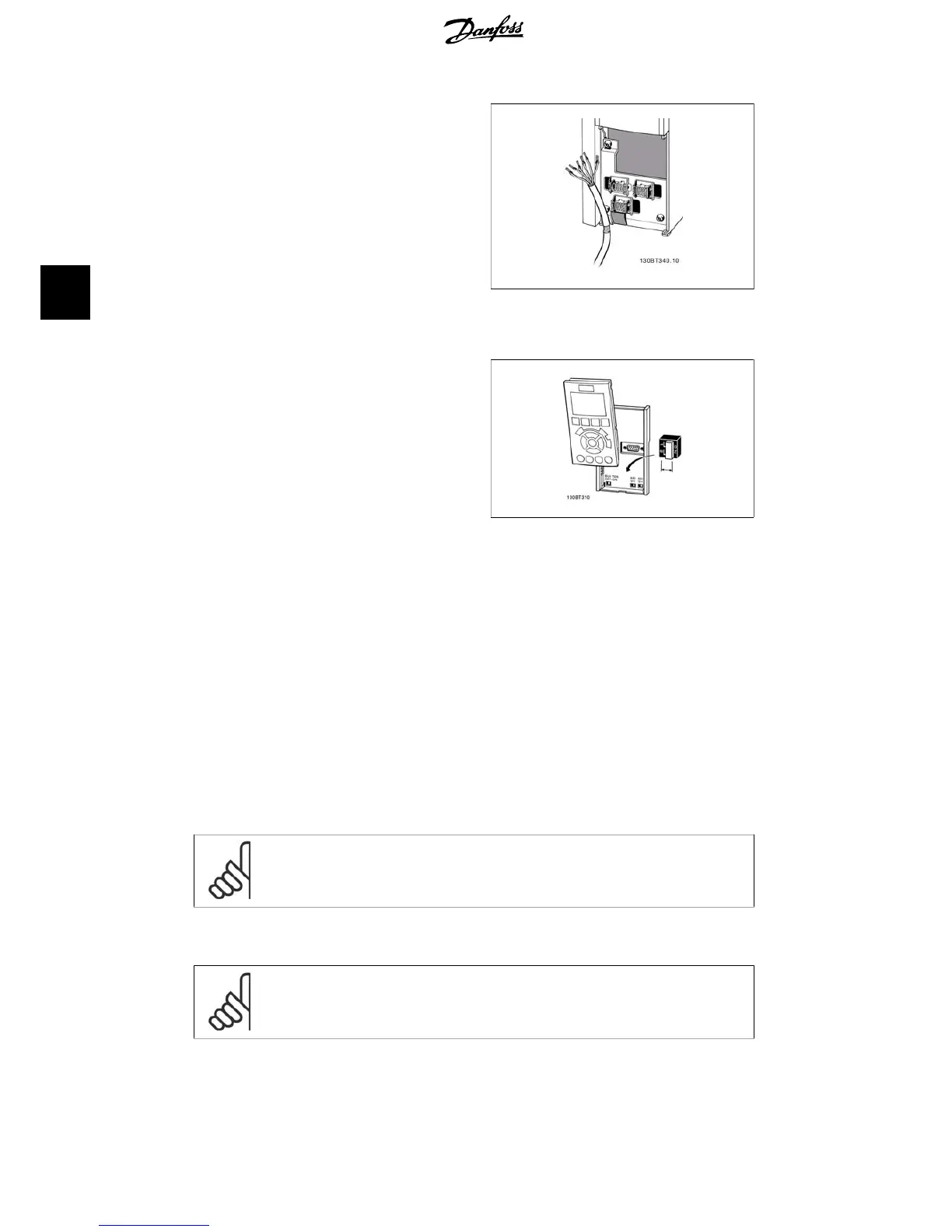

4.1.20. Switches S201, S202, and S801

Switches S201 (Al53) and S202 (Al54) are

used to select a current (0-20 mA) or a voltage

(0 to 10 V) configuration of the analog input

terminals 53 and 54 respectively.

Switch S801 (BUS TER.) can be used to enable

termination on the RS-485 port (terminals 68

and 69).

Please note that the switches may be covered

by an option, if fitted.

Default setting:

S201 (A53) = OFF (voltage input)

S202 (A54) = OFF (voltage input)

S801 (Bus termination) = OFF

Illustration 4.30: Switches location.

4.2. Final optimization and test

4.2.1. Final optimization and test

To optimize motor shaft performance and optimize the frequency converter for the connected

motor and installation, please follow these steps. Ensure that frequency converterfrequency con-

verter and motor are connected, and power is applied to frequency converter.

NB!

Before power up ensure that connected equipment is ready for use.

Step 1. Locate motor name plate..

NB!

The motor is either star- (Y) or delta- connected (). This information is located on

the motor name plate data.

4. Electrical installation VLT

®

HVAC Drive Operating Instructions

38

MG.11.A4.02 - 09.10.06. VLT

®

is a registered Danfoss trademark

4

Loading...

Loading...