1.3.4 Electrical Installation in General

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. Copper conductors required, (75 °C)

recommended.

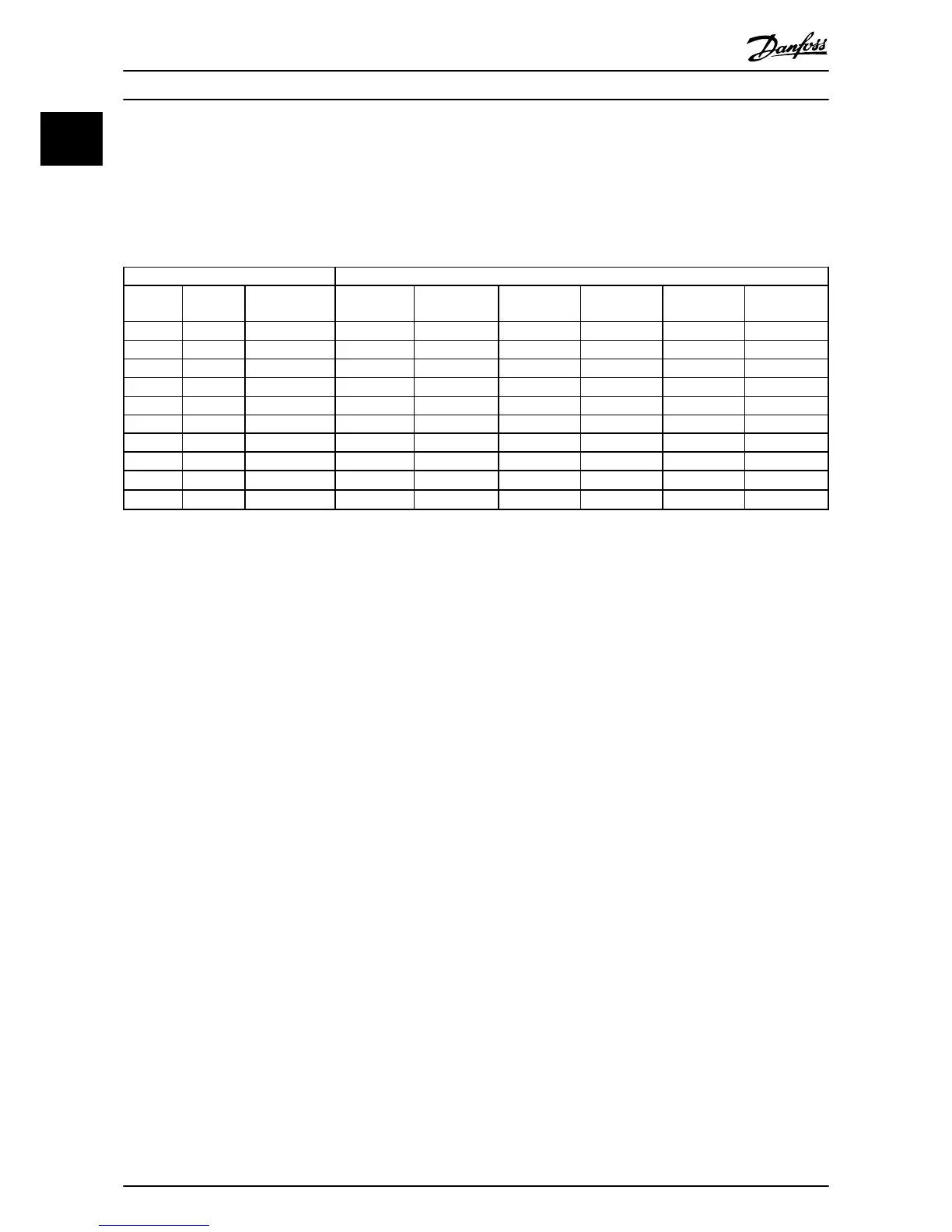

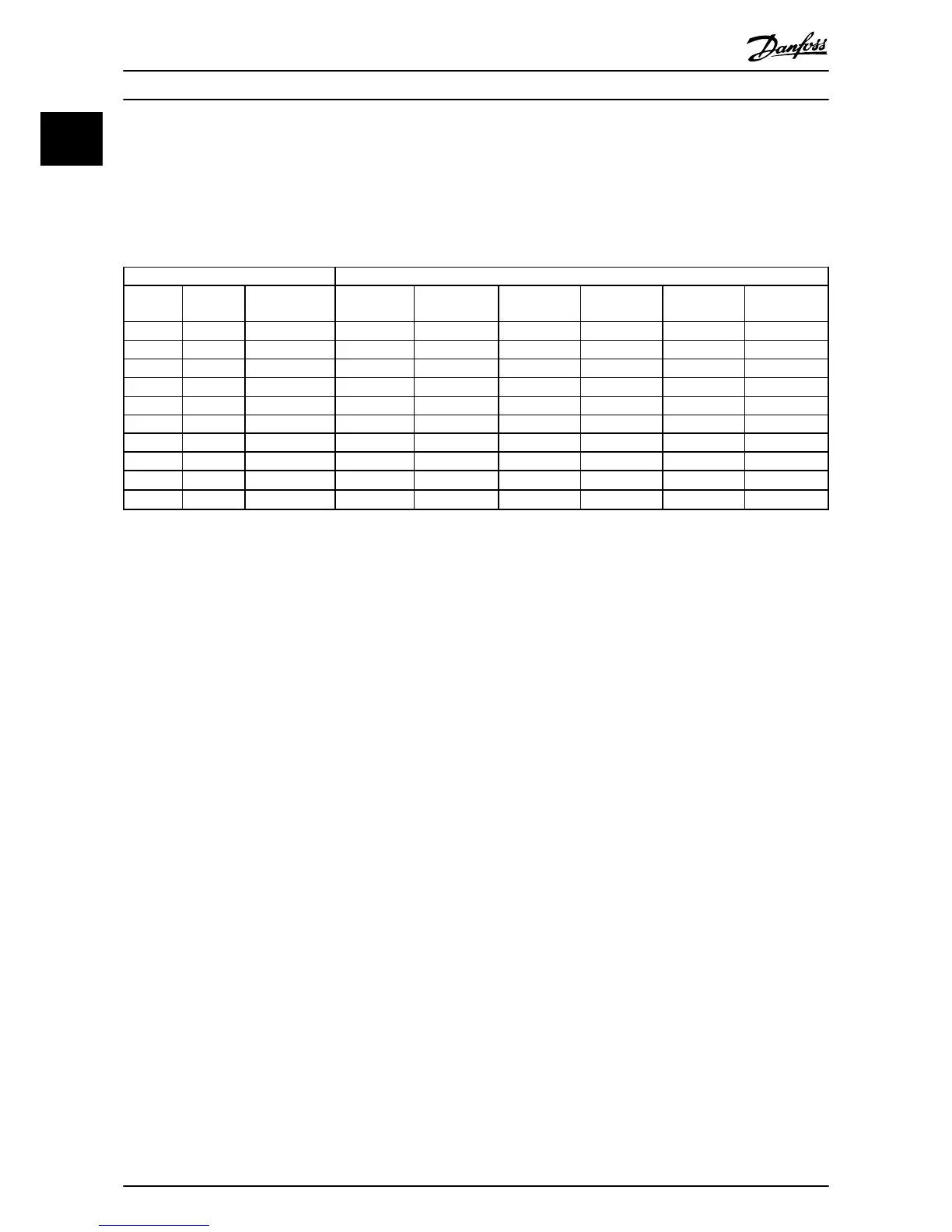

Power [kW] Torque [Nm]

Frame IP class 3x380-480 [V] Line Motor DC connection Control

terminals

Earth Relay

H1 IP20 0.37-1.5 1.4 0.8 0.8 0.5 0.8 0.5

H2 IP20 2.2-4 1.4 0.8 0.8 0.5 0.8 0.5

H3 IP20 5.5-7.5 1.4 0.8 0.8 0.5 0.8 0.5

H4 IP20 11-15 1.2 1.2 1.2 0.5 0.8 0.5

H5 IP20 18.5-22 1.2 1.2 1.2 0.5 0.8 0.5

H6 IP20 30-45 4.5 4.5 - 0.5 3 0.5

H7 IP20 55 10 10 - 0.5 3 0.5

H7 IP20 75 14 14 - 0.5 3 0.5

H8 IP20 90

14

1

14

1

- 0.5 3 0.5

H8 IP20 90

24

2

24

2

- 0.5 3 0.5

Table 1.8

1

Cable dimensions

≤

95 mm

2

2

Cable dimensions >95 mm

2

1.3.5 Connecting to Mains and Motor

The frequency converter is designed to operate all

standard three-phased asynchronous motors. For

maximum cross-section on wires, see 1.8.1 Mains Supply

3x380-480 V AC.

•

Use a shielded/armored motor cable to comply

with EMC emission specifications, and connect

this cable to both the decoupling plate and the

motor metal.

•

Keep motor cable as short as possible to reduce

the noise level and leakage currents.

•

For further details on mounting of the

decoupling plate, see instruction, FC 101

Mounting of decoupling plate for H1 and H2.

•

Also see EMC-Correct Installation in the Design

Guide.

1. Mount the earth wires to earth terminal.

2. Connect motor to terminals U, V and W.

3. Mount mains supply to terminals L1, L2 and L3

and tighten.

Quick Guide

VLT

®

HVAC Basic Drive Cascade Controller Quick Guide

6 MG18F402 - VLT

®

is a registered Danfoss trademark

11

Loading...

Loading...