48

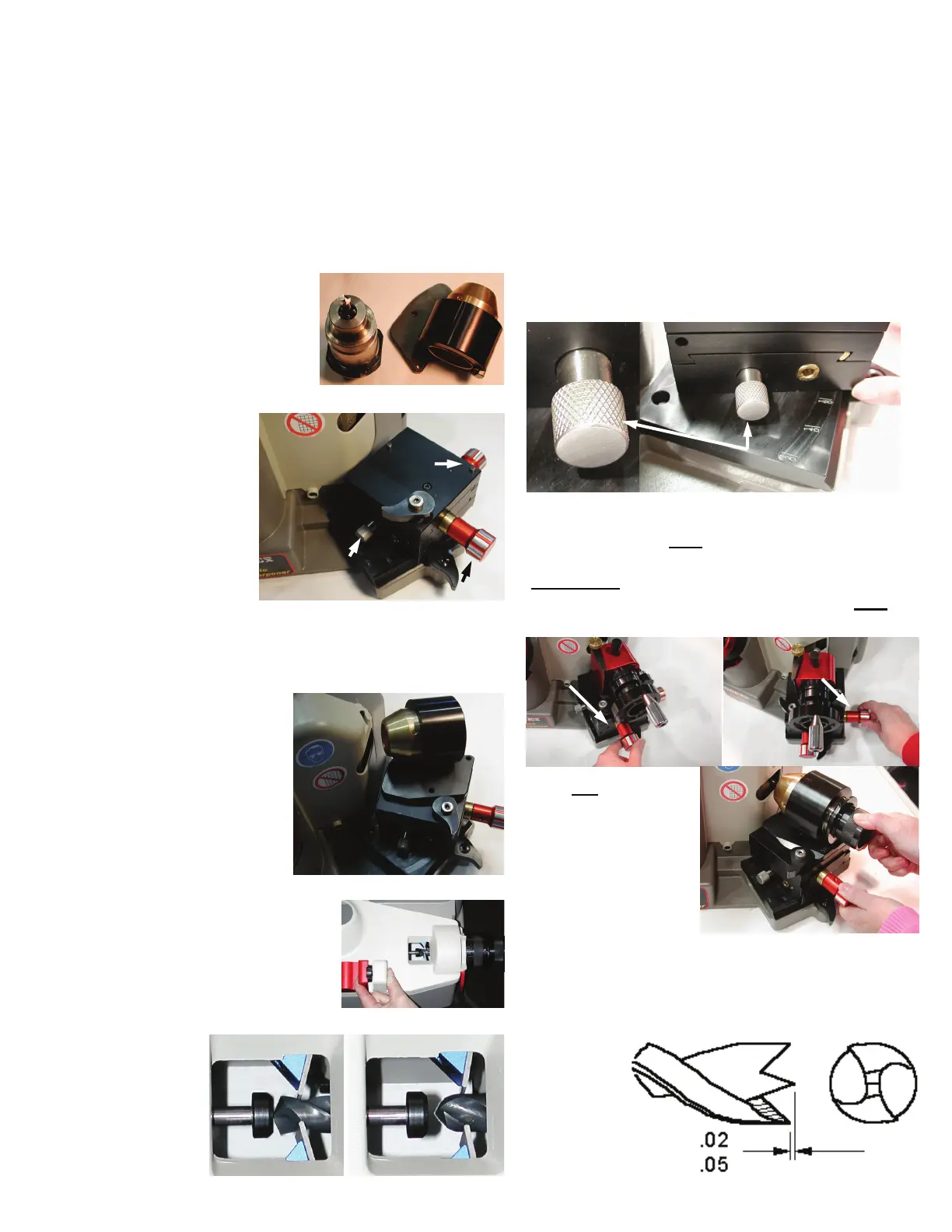

Congratulations on the purchase of the Darex XT-

3000 Brad point Attachment. (LEX200) This

attachment consists of 2 pieces, 1 Sharpening

Fixture, SA16900BA and 1 - 3mm – 12mm Chuck,

SA16916TA. (The 12mm – 21mm Chuck,

SA16918TA is available

as an optional accessory)

Both components are

laser marked with a Brad

Point icon to minimize

confusion with other XT-

3000 attachments.

SETTING UP:

To sharpen a

Brad Point, you

will have to

remove the

standard

sharpening fixture

and replace it

with the X-Y

Table (LEX100).

The Brad Point Attachment works in conjunction

with the X-Y Table. By now you are familiar with

the ‘quick’ disconnect feature or your XT-3000.

Begin by removing the

current sharpening

fixture and replacing it

with the X-Y Table.

Secure it in place by

rotating the Docking

Lever CW. In much

the same manner,

secure the Brad Point

Sharpening Fixture to

the X-Y Table.

ALIGNING THE DRILL:

The alignment of the drill

happens in the XT-300

0

Alignment Tube. Loosen the

Timing Tube Lock lever

and

position

the Tube

@ 118°.

Push the

lever down

to lock the

tube. Align

the drill as

you normally would.

SETTING UP THE X-Y TABLE:

Brad point drills are ground with the X-Y Table

positioned at approx. the 160° mark. Loosen the

Pivot Lock Knob and rotate the X-Y Table to 160°.

Lock the Table.

SHARPENING:

With the XT-3000

OFF

, place the Chuck in the

sharpening mechanism making sure the drill

DOES NOT

contact the grinding wheel. If it does,

use the X-Y axis knobs to position the drill

OFF

the wheel.

Turn

ON

your XT-

3000. Using the same

Axis Knobs, start to

move the drill into

the grinding wheel

while rotating the

Chuck. This fixture is

meant to re-sharpen

existing drills. During the sharpening process,

should you remove an

excessive amount of

material, due to damage, it will be necessary to

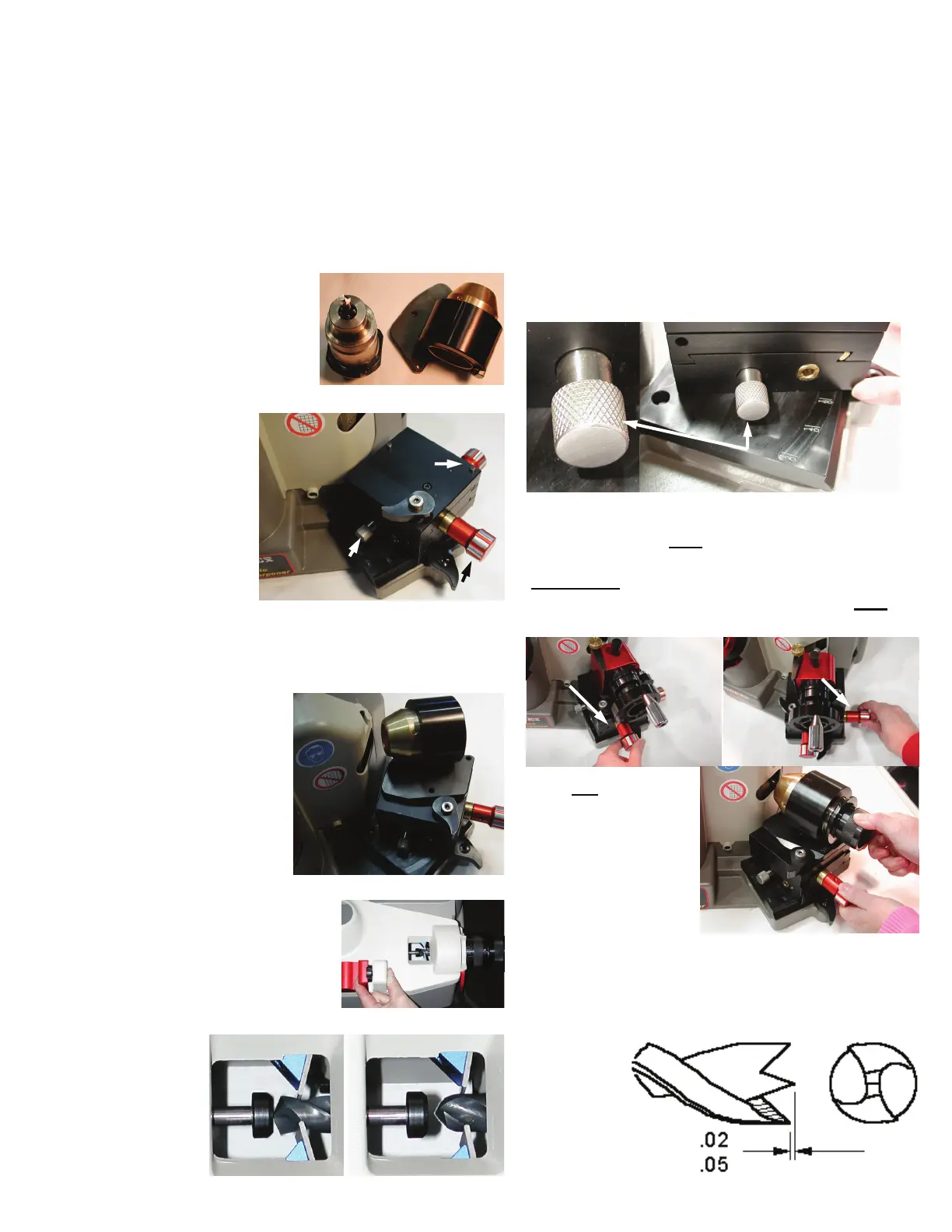

re-align the drill and sharpen again. Refer to the

diagram

below for

examples of

proper drill

geometry.

BRAD POINT ATTACHMENT

LEX200

CORRECT INCORRECT

Pivot Lock Knob

X-Axis Knob

Y-Axis Knob

Y-Axis Knob X-Axis Knob

Pivot Lock Knob

Loading...

Loading...