DX8200 Controller

Quick Reference Guide

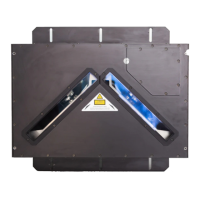

Figure A

Figure B

Control Panel

Product Label

Laser Output Windows

Mounting Rails

Laser Warning Label 1

2

3

4

5

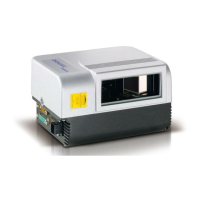

Figure C

Host Interface Connector

Reserved Connector

Lonworks Network Connector

RS232 Debug Connector

Ethernet connector

Power ON LED

Presence Sensor LED (N.A.)

Encoder LED

Good Read LED

TX Data LED

Network LED

1

5

6

7

8

9

10

11

2

3

4

VAC Power Panel (for VAC models only)

Fuses, Power Switch, Power Connector,

12

NOTE

For further details on product installation, see the complete Reference Manual. The DX8200

Controller can be configured through the Windows-based Genius™ software program available

on the CD-ROM included with this product.

10

2

1

7

8

9

1

2

3

4

5

6

11

12

4

5

3