L O O K

Operating instructions and warnings

only for qualified personnel

10

4.5 Instructions for risk-free operation

WARNING With not self-locking models, with same leaf

length, reduce of 1/3 the door admissible weight compared to

what indicated in “Length-weight” chart.

WARNING In case the leaf is more than 2 m long or in

case you use not self-locking models, an electric-lock must be

installed to hold the gate in closing position.

4.5.1 Installation, assembly and disassembly

The following operations are essential to the correct laying

of the product:

• Thecarefuldefinitionoftheentireautomaticopeninglayout

(see also “6 Complete Closing Assembly”); in particular,

after carefully assessing the characteristics of the supports

and the gate, the attachments must also be designed and

positioned according to the angle of opening desired (see

F2, F3 Page 38-39).

• Verify that any mechanicalfeature of the gate are in good

conditions and allows a safe automation. Moreover check the

balancing, gate has to correctly and freely move on its hinges

and once stopped in any position, it has to stay blocked.

The fastening of the attachments must be performed with

extra care on both pillars and gate, here are the dimensions

suggested by DEA SYSTEM (see F3 page 39). Pay extra at-

tention to the horizontal alignment between rear fastening

support and front one.

General considerations to establish the installing dimen-

sions:

• ThesumofA+Bfor90°openingsisequaltoCrodrun

• A+B<Ctoincreasetheopeningangle

• AandBlowerthanwhatsuggested,involveahigherdoor

tangential speed

• If A and B are 5 cm greater than what suggested, limit

switches (if foreseen) adjustment won’t be possible

To install the operator proceed as follows:

• Weldorscrewtherearfasteningsupporttothepillar,inpre-

fixed position

• ApplyLOOKtotherearfasteningsupport

• Executethemanualunlockingoperation(seefollowingpara-

graph) and take off completely the rod

• LockLOOKagainandturntherodhalfway

• FixthefrontalfasteningsupporttoLOOKrod

• Weldorscrewthefrontalfasteningsupporttothedoor(with

door completely closed), by keeping LOOK in an horizontal

position

• Unlock again and make a complete opening and closing

cycle, this is to check that gate moves freely and without any

hindrance (with cover rod)

WARNING In order to make the structure sufficiently strong,

reinforcement plates to be fixed to attachments may be ne-

cessary

WARNING Grease pins before assembly

• Forversionsthatforeseethecoverrod,adjustlimitswitches

while assembling (see page 34)

4.5.2 Starting and adjustment

WARNING During the connection phase, fasten the

electric cables with appropriate clamps near the terminal

boards and, when possible, unsheathe the cables to avoid

they are too long.

LOOK must be electrically connected to a DEA SYSTEM con-

trol panel; refer to the instructions provided for such device for

further information.

For LOOK wiring, proceed as follows (se also page 33):

24V/230V standard version

• RemovetheplasticcoverpositionedunderLOOK

• Openoneoffourshapedholesandchoosewherethecable

exit has to be

• Introducethecableclampandfixitbyitsnut

• Insertthepowersupplycableintotheclamp(comingfrom

the control panel): A quadrupole cable suitable for external

applicationswitha4x1mm²section(or2x1,5mm²for24V

operators)(minimum H05RN-F type) coming directly from

the control panel (without any connection and shunt box)

and supplied by the installer;

WARNING: do not remove too much outer insulation on the

power supply cables.

• Executemotorconnectionsasindicated:

24/230V version with limit switches

• Fortheoperatorpowersupplyconnectionfollowtheinstruc-

tions of the basic version.

• Openasecondholeintheplasticcoverandapplythese-

cond provided cable clamp (a reduced M16).

• Usea3x0,75mm²cable(notsupplied)andlookatthedia-

gram at page 11 for a correct limit switches wiring to the

control panel.

230V version with encoder

• Fortheoperatorpowersupplyconnectionfollowtheinstruc-

tions of the basic version.

• Openasecondholeintheplasticcoverandapplythesecond

provided cable clamp (a reduced M16).

• Usea 3x0,5mm² LiYY (DEAart.182021)to be ordereda

part) and follow the diagram on page 11 to correctly connect

the encoder to the control board.

• Usethecablewithpanduitconnectorsuppliedinthekittocon-

nect the previously used cable to the control board, by using the

clamp 3 “poli” inside the package.

WARNING: Maintain the ground conductor at a major length

respect the active conductors so that, if the cable exit from its

fixing housing, the active conductors tighten up as first.

WARNING: Respect the Phase-Neutral polarity of the tension as

explained by the instructions manual of the control panels

of LOOK.

• Re-assembletheplasticcoverensuringthatanycabledonot

touch moving parts of the operator

WARNING: LOOK limit switches have been exclusively foresaw

to directly connect their inputs to the control panel and so

they are submitted to a very safety low tension. Therefore

keep a proper distance between limit switches cables and

power supply cable of 230V operator.

WARNING: while installing, maintain a proper distance between

the power cable conductors and the operator

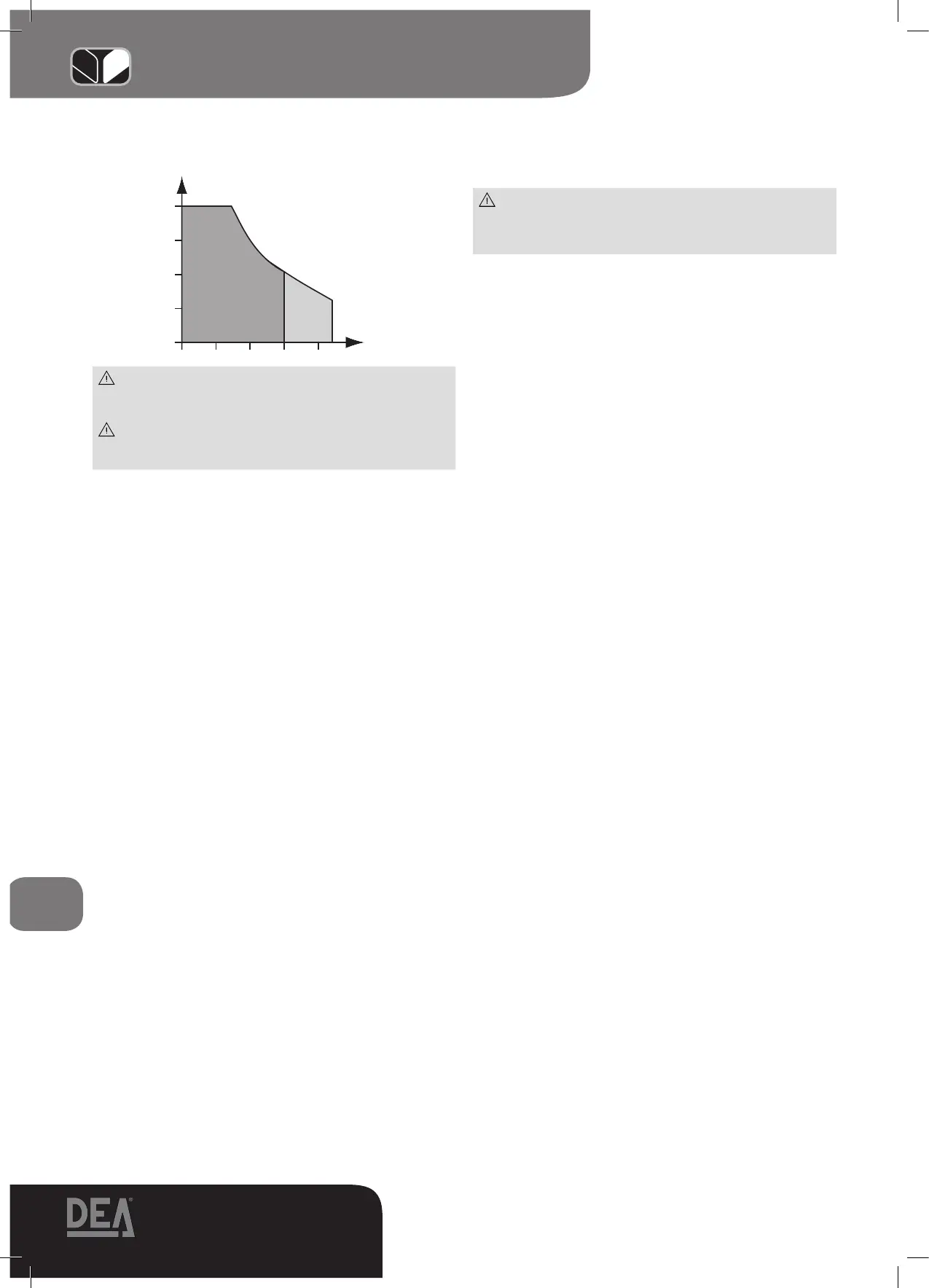

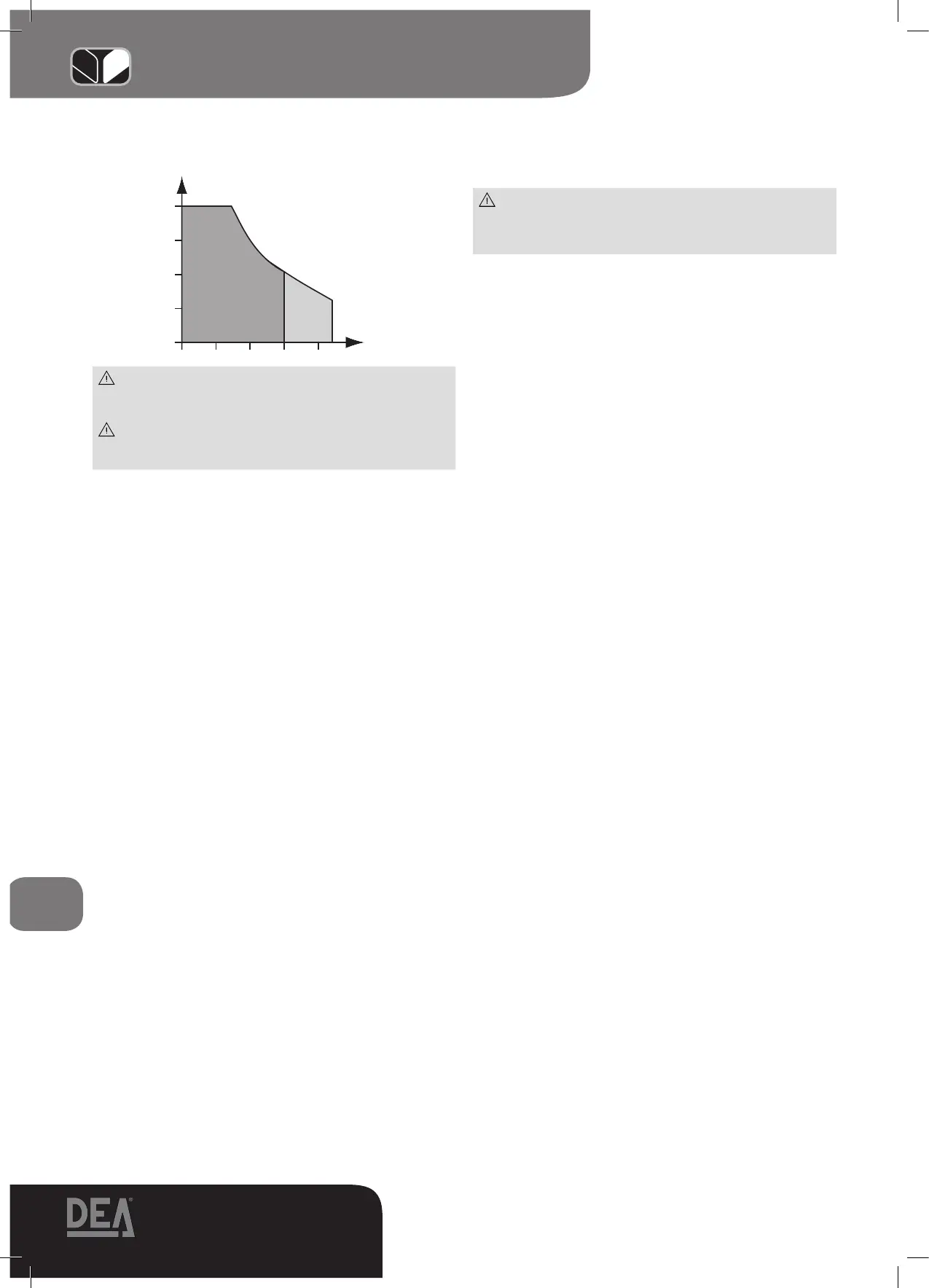

“LENGTH-WEIGHT” chart

1 2 3 4

800

600

400

200

m

350, 351, 352, 371, 372

Kg

355, 356

373, 374

Loading...

Loading...