MAN-PTS-GB, Revision 9, BSC, 15-FEB-2017 16/46

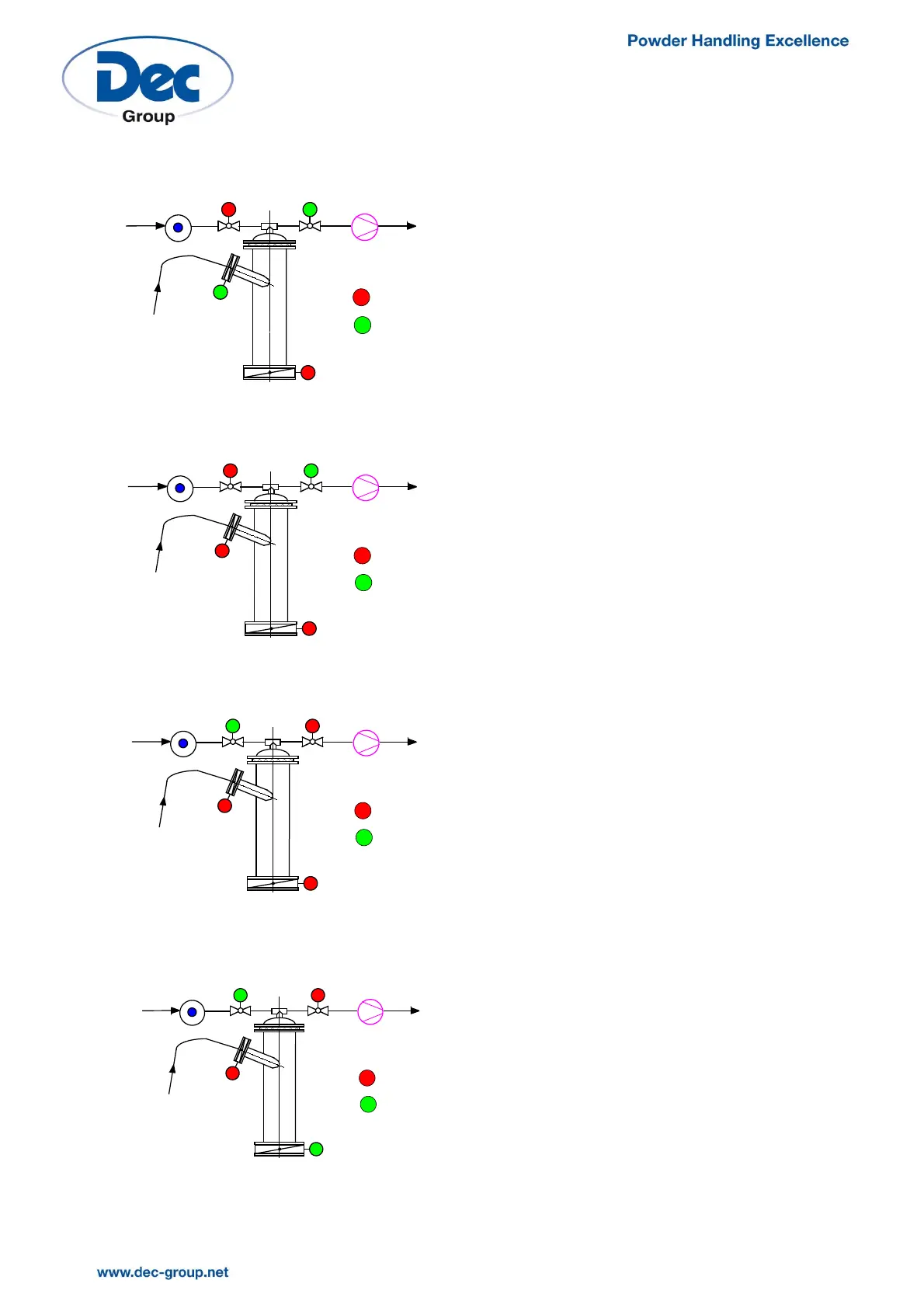

After a predetermined time, the inlet

valve V1 opens. The product is sucked

into the chamber with the vacuum

created by the vacuum pump.

After a given time, when sufficient

powder has been filled into the PTS

chamber, inlet valve V1 closes (the filling

rate is controlled by a timer).

The vacuum valve V3 remains open in

order to evacuate the residual air still

present in the chamber.

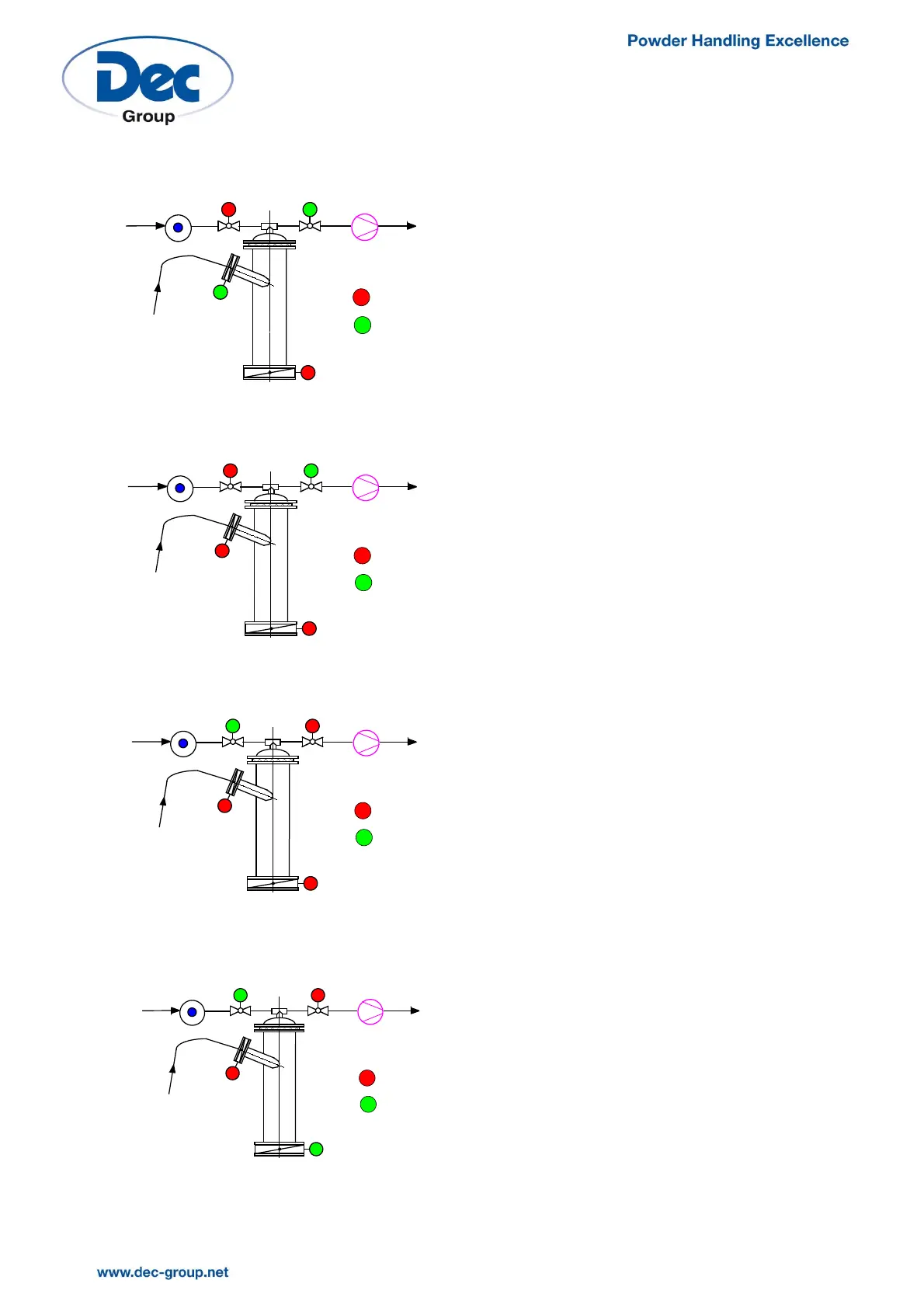

When the vacuum valve V3 closes, the

valve V4, which is connected to a

pressure source (compressed gas),

opens. The gas used for the system can

be selected according to the process

conditions. Compressed air or nitrogen is

used in most cases. The residual vacuum

is eliminated by opening the pressure

valve V4, and the chamber is put under

pressure.

The product outlet valve V2 can then

open. The chamber is emptied by the

pressure effect and the product is

introduced into the receiver. The filter is

cleaned in a countercurrent fashion

during the discharge cycle by the

stream of gas. This allows maintaining

the initial suction capacity for the next

cycle. The outlet and pressure valves V2

and V4 close after a given time.

VACUUM

PUMP

PRESSURE

POWDER

V1

Valve closed

Valve open

V2

V3

V4

VACUUM

PUMP

PRESSURE

POWDER

V1

Valve closed

Valve open

V2

V3

V4

VACUUM

PUMP

PRESSURE

POWDER

V1

Valve closed

Valve open

V2

V3

V4

VACUUM

PUMP

PRESSURE

POWDER

V1

Valve closed

Valve open

V2

V3

V4

Loading...

Loading...