MAINTENANCE NOTICE

NM-230 index 18

Page 36/55 September 2020

8 CHANGING SEALS AND REASSEMBLY

8.1

INTRODUCTION

Our valve components are listed and identified in this notice, together with all the

information you need to order your spare parts.

8.2

ASSEMBLING THE ACTUATOR

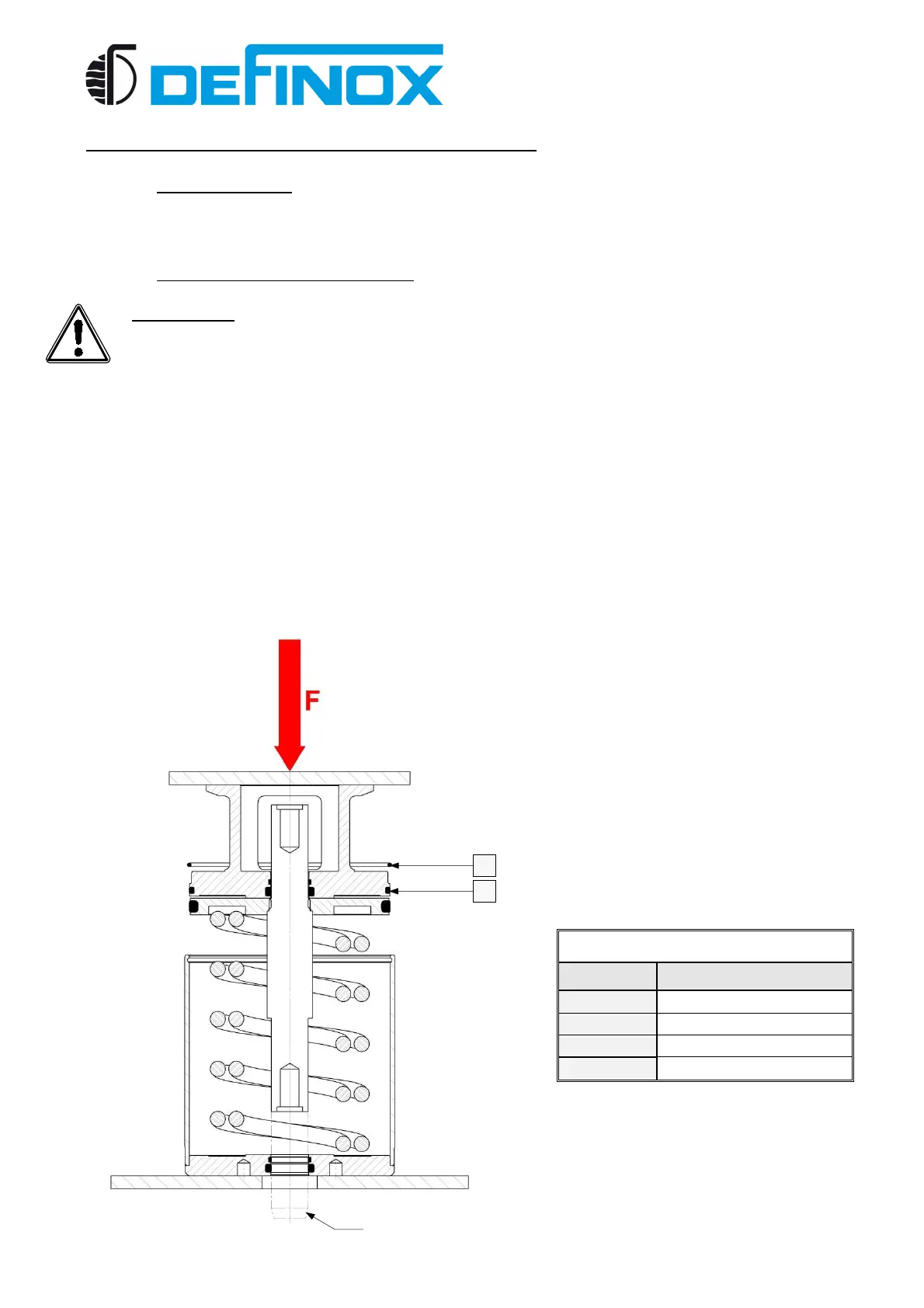

CAUTION: For changing the actuator configuration from NC (Normally Closed) to NO

(Normally Open), see the following chapter.

This procedure is performed in the reverse order to disassembly. However, it is necessary

to take into account the following information :

• A guide pin centred on the actuator stem ensures that the piston is properly centred in the

body. It also avoids the piston jumping if the spring(s) slip(s) sideways during compression.

• Before reassembling the parts, ensure that the assembly is lubricated with an appropriate

lubricant (water-resistant and temperature-resistant food grade grease → E.g., for information:

4025 H1 QUINPLEX by Lubrication Engineers, see § 9.10). Ensure that the grease used is

compatible with the elastomer seals.

• Take care not to damage the lantern seal [37] when fitting it with the press.

• Ensure that the snap-ring [31] is properly positioned in the recess of the body before releasing

pressure.

• Test operation of the actuator before continuing assembly.

Guide pin (CAUTION pin protrudes during assembly)

Guide pin No.

DN

references

31

37

Loading...

Loading...