Chapter 8 ParametersASDA-A2R Series

Revision December, 2014

8-199

Command code

000Eh

Perform E-Cam alignement immediately and write the

correction value into the specified PR.

Macro parameters

P5-93 = DCBA:UZYX (8 digits, HEX)

YX (PR number) = 0~0x3F, it is invalid when the value

is set to 0.

UZ (Max. alignment correction rate) = 0~0x64 (%)

A (Trigger the specified PR directly) = 1: On, 0: Off

DCB = has to be set to 0

P5-94 (DI delay time compensation) = -25000 ~

+25000; Unit: usec.

P5-95 (available forward rate) = 0 ~ 100 (%)

P5-96 (target position of alignement X); Unit: pulse

number of master axis = 0 ~ (P5-84/P5-83) – 1.

Monitor variable 062(3Eh): It displays the current engaged position of

master axis (X)

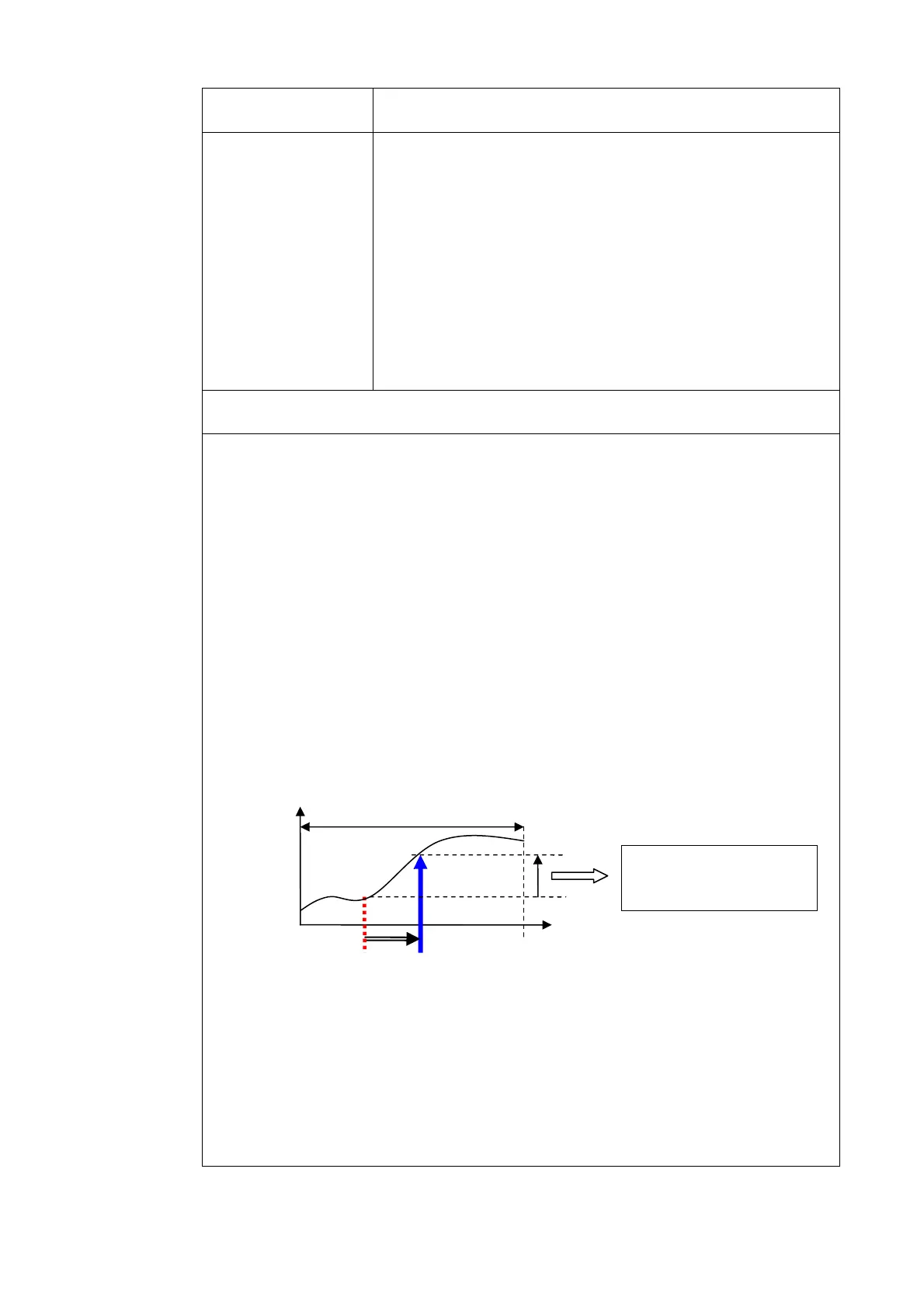

This macro command can move the engaged position to the alignment

target position (X) when E-Cam is engaged. And write the alignment

correction value into the specified PR.

During E-Cam operation (When E-Cam is engaged), if desire to quickly

align the E-cam position to the mechanical referral point, sensor can be

used to trigger DI.EVx to execute this macro command.

After E-Cam alignment is completed, the engaged position will move to the

new position. The excess or not enough moving distance after E-Cam

operates one cycle is called alignment correction value. It will be written into

PR specified by P5-93.YX. PR incremental command can be used to

compensate this value so that the slave axis position will remain and offset

the phase of E-Cam to align the referral position of machine. For some

applications, set value of P5-93.YX to 0 will do. Please note that PR can be

executed only when triggering the host controller.

*P5-93.UZ is able to limit the max. correction rate. The alignment target position

★ will be different from P5-96.

|alignment target position★ – current engaged position| / L <= P5-93.UZ %

*DI time delay compensation can be set via P5-94, it can correct the error caused

by different speed of motion.

Alignment target position

P5-96

Current engaged

position

Pulse number of master axis after rotating a cycle: (P5-84/P5-83) =

L

Master axis position (X)

Slave

axis

position

(Y)

lignment correction

value = Y_Diff

Loading...

Loading...