ASDA-M Chapter 7 Motion Control

Revision December, 2014 7-25

degrees. (Note 9)

DATA1 is the setting of arc starting angle. DATA2 is the setting of arc moving angle.

Note 9: The unit of angle is 0.5 degrees, which means the input value is two times of the

setting value. For example, if it is set to 90 degrees, the input value will be 180.

Command source: P6-02~P7-99 of the third axis, parameter DW1 (DATA-32BIT), 99 PR in

total.

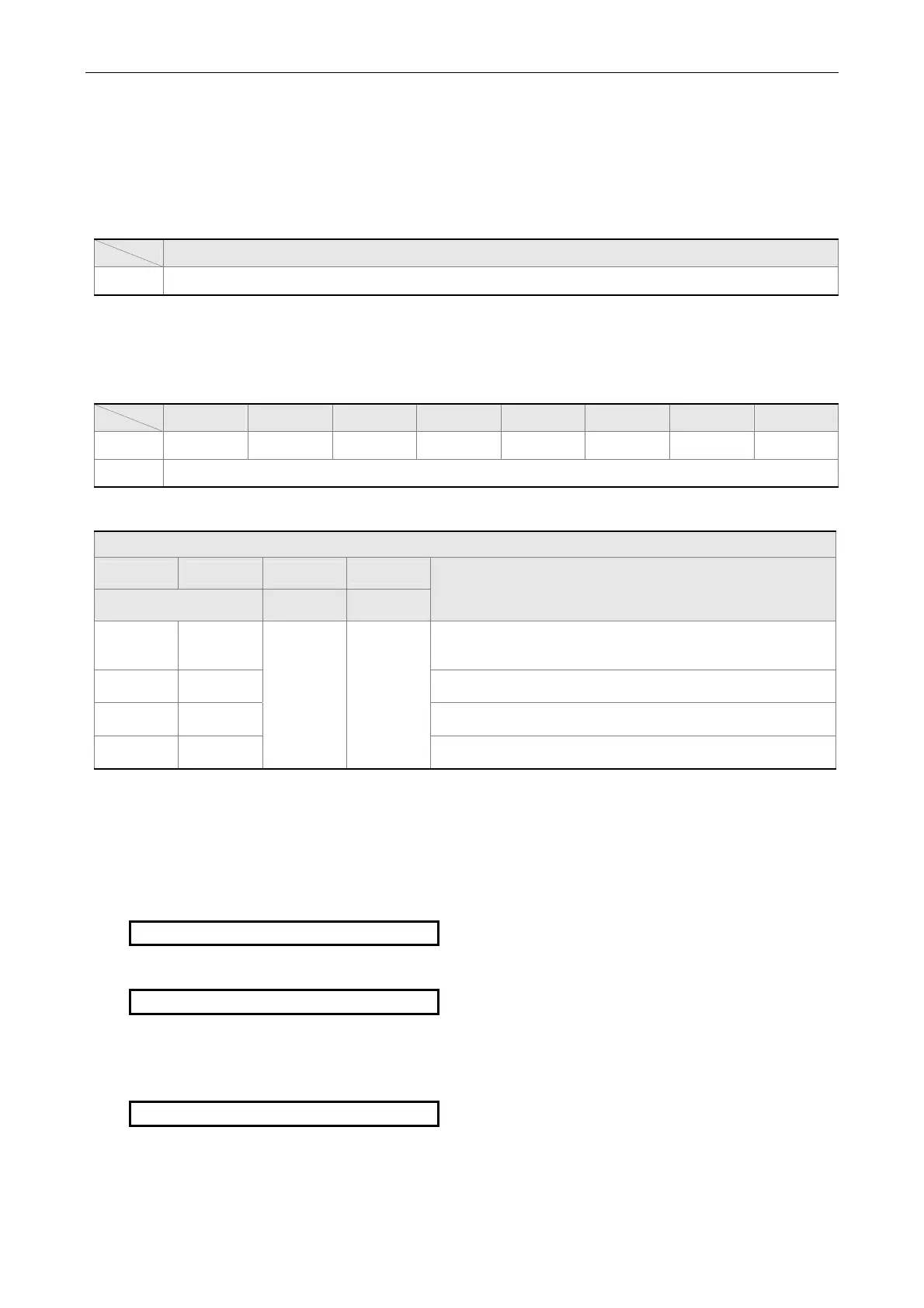

31 ~ 0 BIT

DW1 DATA (32 bit )

The source of X command is the setting of the height of helix. Unit: user unit (Pulse of User

Unit)

13) Two-axis circular interpolation: TYPE = F, execute the function of two-axis circular

interpolation

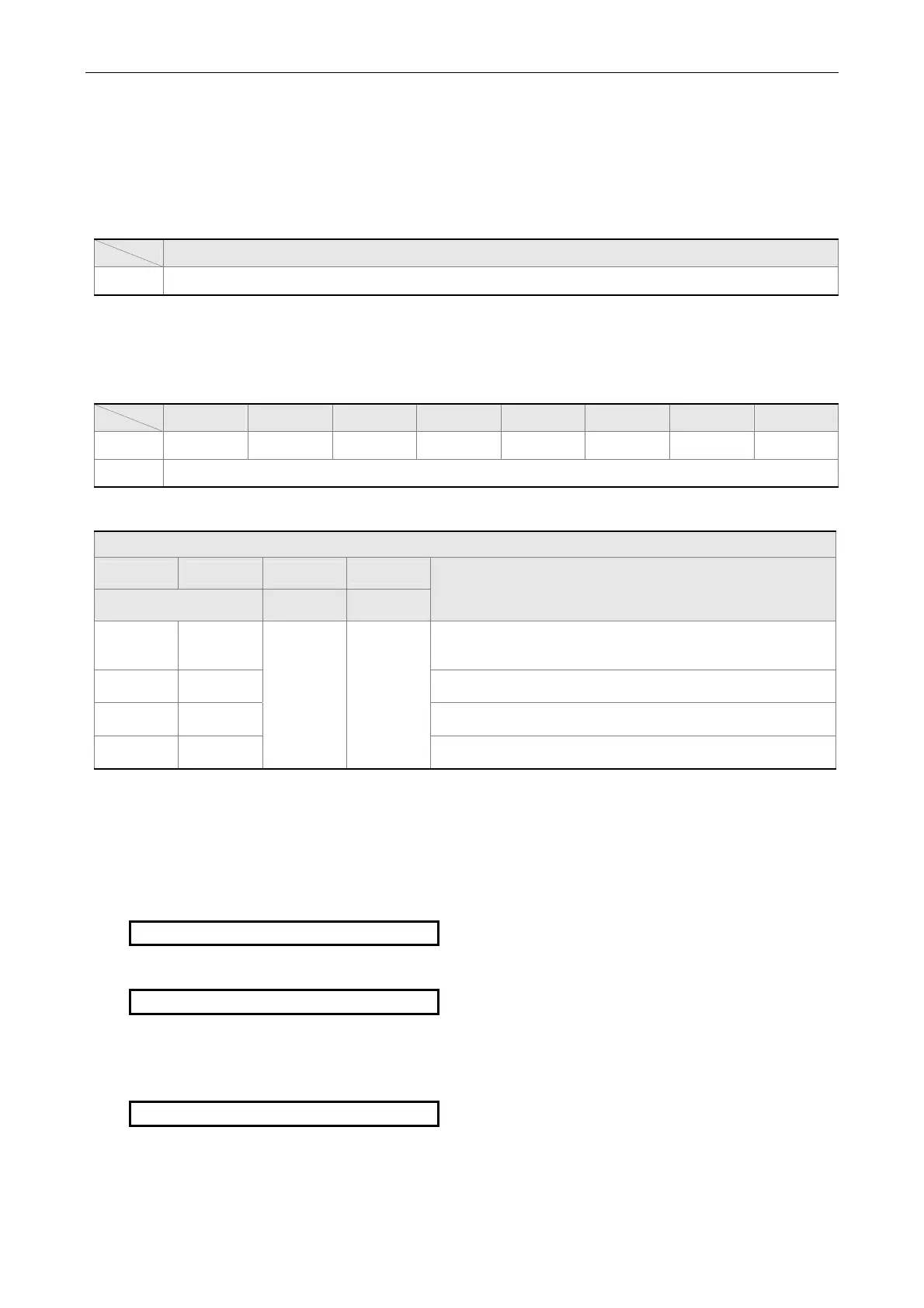

31 ~ 28 27 ~ 24 23 ~ 20 19 ~ 16 15 ~ 12 11 ~ 8 7 ~ 4 3 ~ 0 BIT

DW0 SEL OVLP DLY VSPD VDEC VACC OPT F

DW1 DATA (32 bit ): the setting is determined by different axis

OPT:

OPT Selection

7 6 5 4 BIT

Description

CMD OVLP AUTO

0 0

- -

ngle command: starting angle and moving

angle (Note 10)

1 0

Reserved

0 1

Reserved

- - Reserved

※DI.STP stop and software limit are acceptable.

OVLP: It is allowed to overlap the next PR. When overlapping, please set DLY to 0.

AUTO: Position reached and the next PR is loaded automatically.

CMD: The calculation of the position command termination (Cmd_E) is as follows:

Note 10: angle command – need to enter the starting angle and moving angle

VACC /VDEC: 0 ~ F, the number of vector acceleration/deceleration (4 BIT)

VACC / VDEC (4) Index P5-20 ~ P5-35

VSPD: 0 ~ F, the number of target vector speed (4 BIT)

VSPD (4) Index P5-60 ~ P5-75

DLY: 0 ~ F, delay time number (4 BIT). The delay after executing this PR. The external INS

is invalid.

DLY (4) Index P5-40 ~ P5-55

OVLP: 0 ~ F, overlap percentage selection (4 BIT) and the overlap percentage selection of

the next PR

Loading...

Loading...