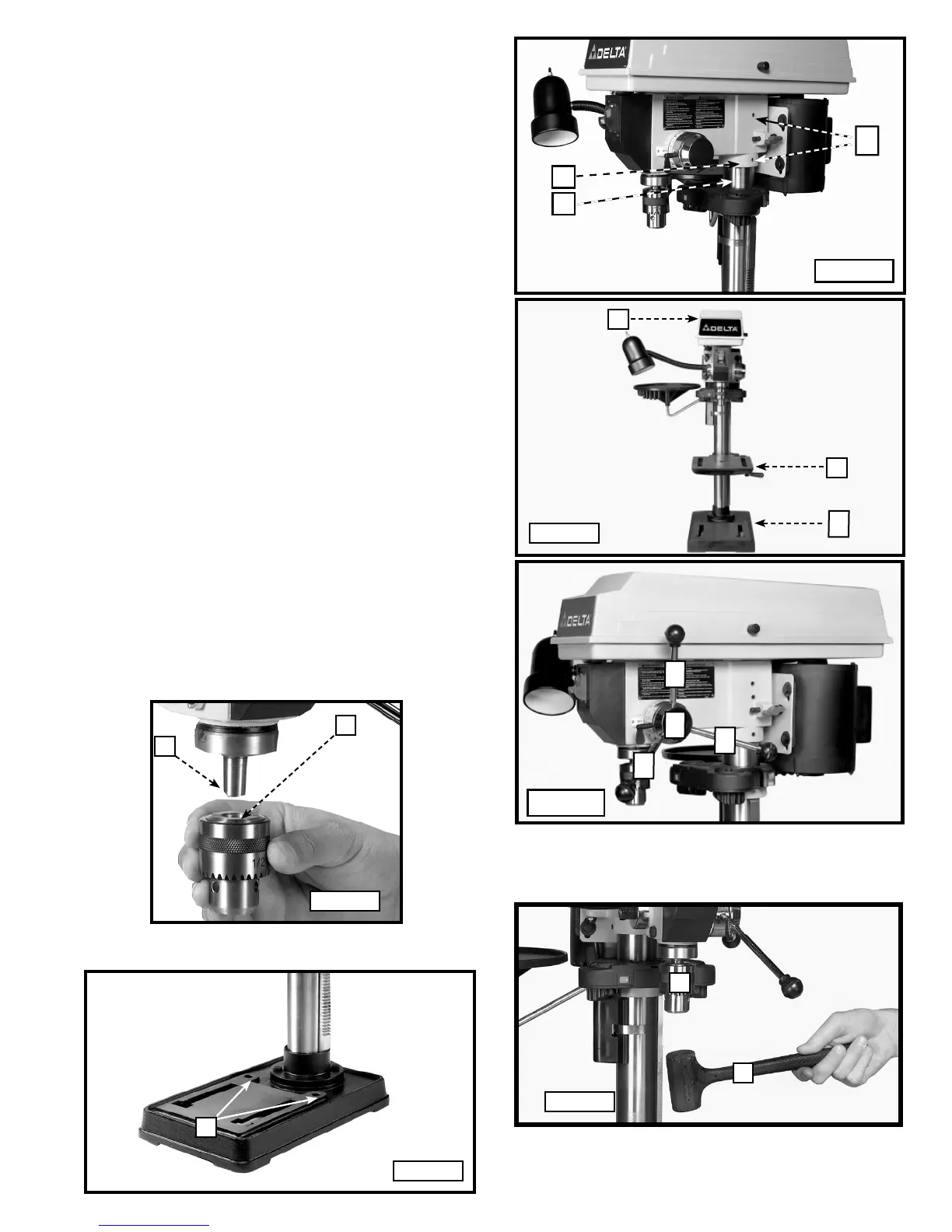

18. Seat the drill press head (N) Fig. 15 on the column

(U). Align the head (A) Fig. 15A, with the table (B) and

base (C). Tighten the two head locking screws (O)

Fig. 15 with the supplied wrench.

19. Thread the three pinion shaft handles (P) Fig. 16 in

the three tapped holes located in the pinion shaft

(S).

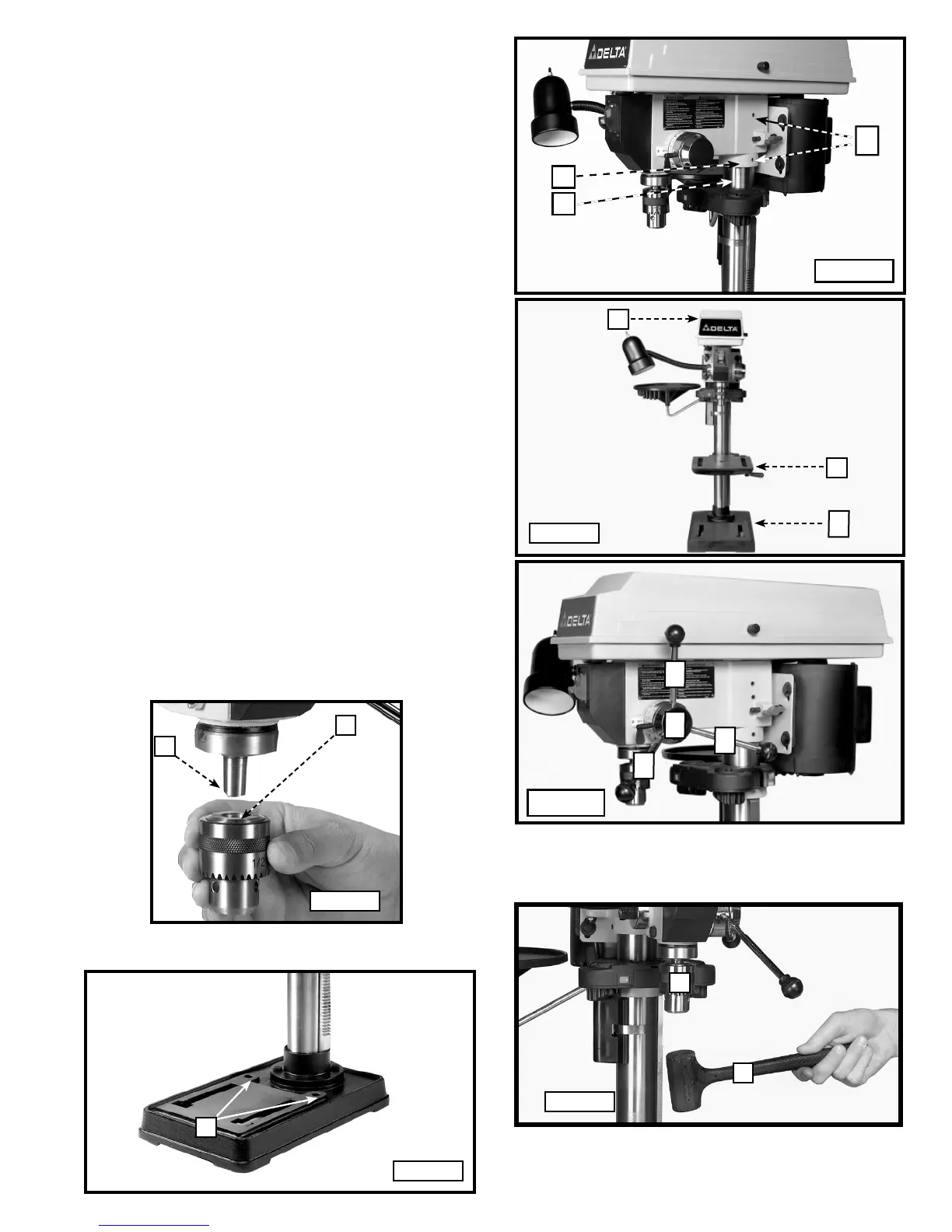

NOTE: Make certain that the spindle taper (Q) Fig. 17

and the tapered hole in the chuck (R) are clean and free

of grease, lacquer, or rust preventive coatings.

NOTE: Household oven cleaner can effectively remove

any substance from the spindle and chuck. Carefully

follow the manufacturer's safety rules concerning its

use.

20. Open the chuck jaws as wide as possible by

turning the chuck sleeve (N) Fig. 18. Hold the

chuck on the taper of the spindle and tap with a

rubber mallet (T) or a block of wood and hammer

to set the chuck (Fig. 18).

IMPORTANT: To avoid damage to the chuck, DO

NOT drive the chuck on the spindle with a metal

hammer.

Fig. 15A

Fig. 17

Fig. 18

Fig. 15

N

U

O

A

B

C

Q

R

N

T

Fig. 16

FASTENING DRILL PRESS TO

SUPPORTING SURFACE

If, during operation, the machine has a tendency to

tip over, slide, or walk on the supporting surface,

secure the machine base to the supporting surface with

an M8x1.25x125mm carriage head screw, 8.5mm flat

washer, 8.5mm lock washer, M8x1.25 hex nut through

the two holes (A) Fig. 19 located in the machine base.

Fig. 19

A

P

P

P

S

13

Loading...

Loading...