Recipe Setting Software Instruction

9

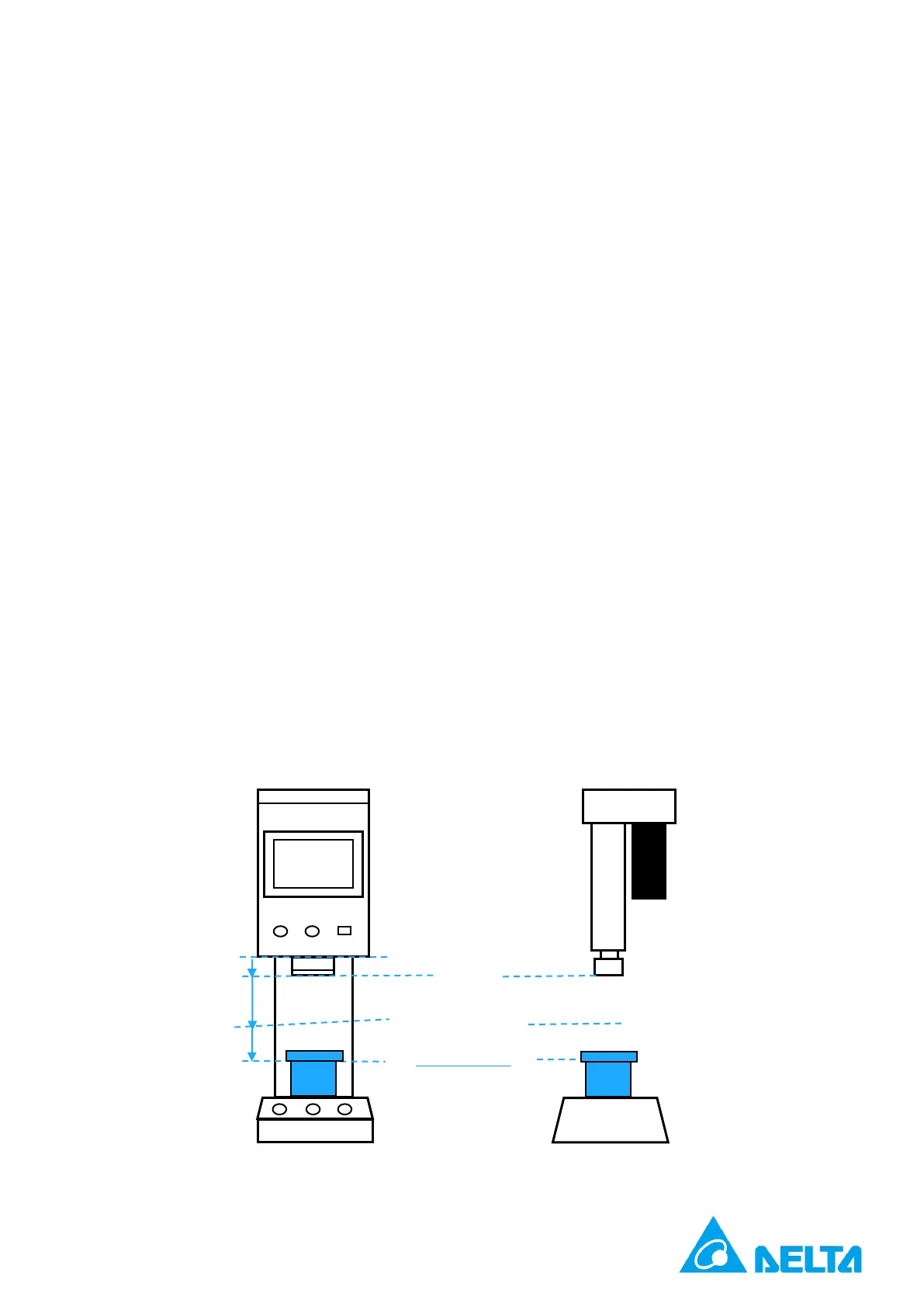

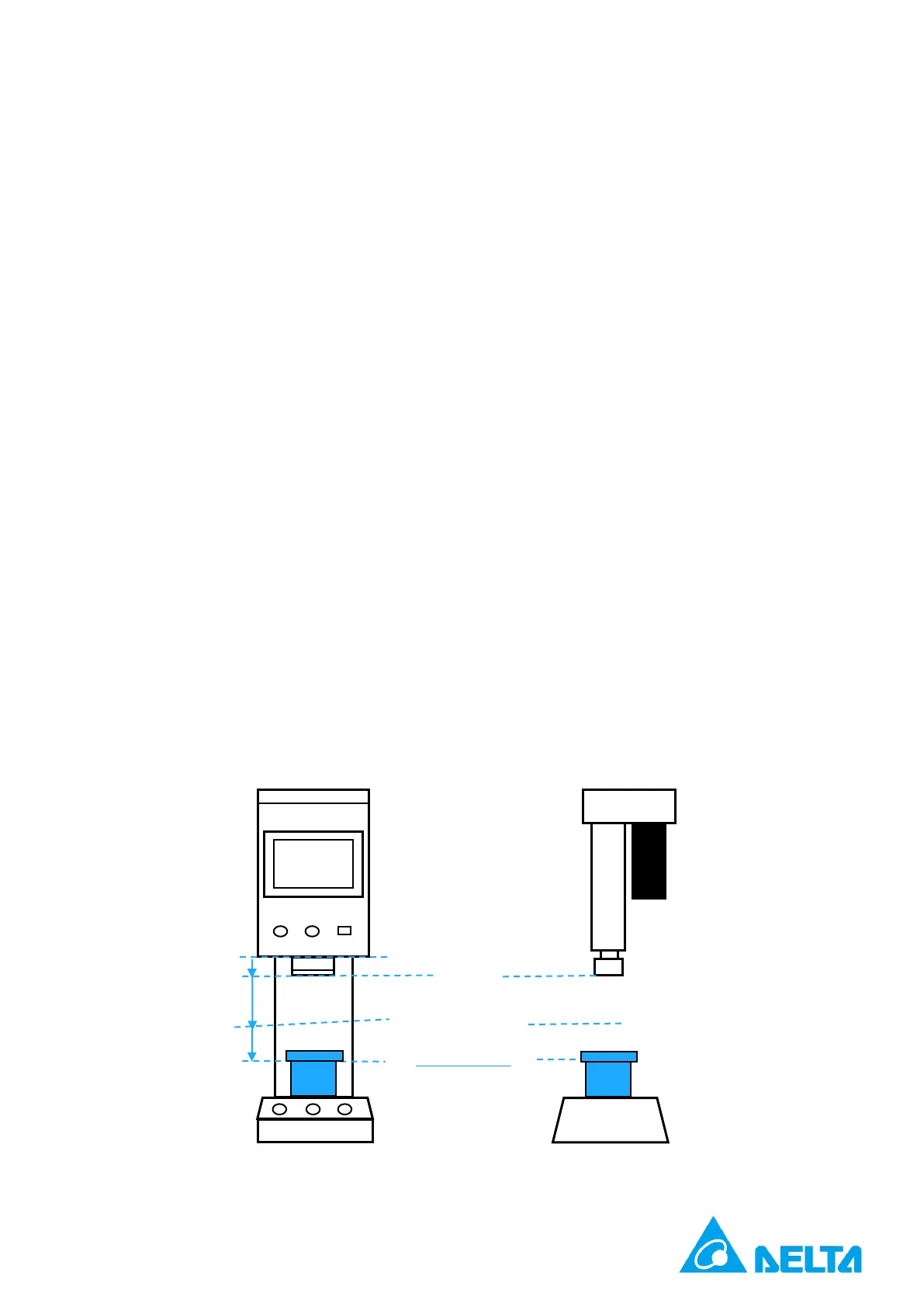

2.3.2 Position mode

Position mode is for clearly defining the end position of the pressing, in which the pressing action is

performed at a constant speed defined by the user during the pressing process.

Pressing conditions: In position mode, the spindle will press down to the [Pressing Position] at the

[Pressing Velocity], and after waiting for the [Pressing Time], execute the next step or return to the

[Working Origin].

Supplementary limiting conditions:

1. These conditions ensure that the force is not greater than the [Max. Force] during the entire

pressing process. If it becomes greater than the [Max. Force], the work piece will be deemed as

NG and the spindle will return to the [Working Origin].

2. If [Dynamic Force Limit] is not turned on, after the spindle reaches the [Pressing Position], the

servo press will check whether the force value is within the range of [Max. Force] and [Mini.

Force]. If it is, the work piece will be deemed as OK; if not, it is deemed as NG.

3. If [Dynamic Force Limit] is turned on, the servo press will automatically calculate the condition

slope for the interval between start and end conditions by the two set condition points. Forces not

within the condition range during pressing will be judged NG and the spindle will return to

[Working Origin].

Working

origin

standby time

Standby velocity

pressing time

Pressing velocity

Original velocity

Loading...

Loading...