Chapter 6 Optional Accessories | VFD-ED

Reactor Model *

1

Recommended Wire Size

Wiring

Method

Qty Applicable Motor Drives

RF008X00A

T60006L2040W453

≤ 8 AWG ≤ 8.37 mm

2

Fig. 6-32

Fig. 6-33

1

VFD022ED21S VFD037ED21S

VFD040ED23S VFD040ED43S

RF004X00A

T60006L2050W565

≤ 4 AWG ≤ 21.15 mm

2

Fig. 6-32

Fig. 6-33

1

VFD055ED23S VFD075ED23S

VFD110ED23S VFD055ED43S

VFD075ED43S VFD110ED43S

VFD150ED43S VFD185ED43S

RF002X00A

T60006L2160V066

≤ 2 AWG ≤ 33.62 mm

2

Fig. 6-32

Fig. 6-33

1

VFD150ED23S VFD185ED23S

VFD220ED23S VFD220ED43S

VFD300ED43S

RF300X00A

T60006L2160V066

≤ 300 MCM ≤ 152 mm

2

Fig. 6-32

Fig. 6-33

1

VFD300ED23S VFD370ED23S

VFD370ED43S VFD450ED43S

VFD550ED43S VFD750ED43S

*

1

: 600V insulated cable wire Table 6-36

Installation

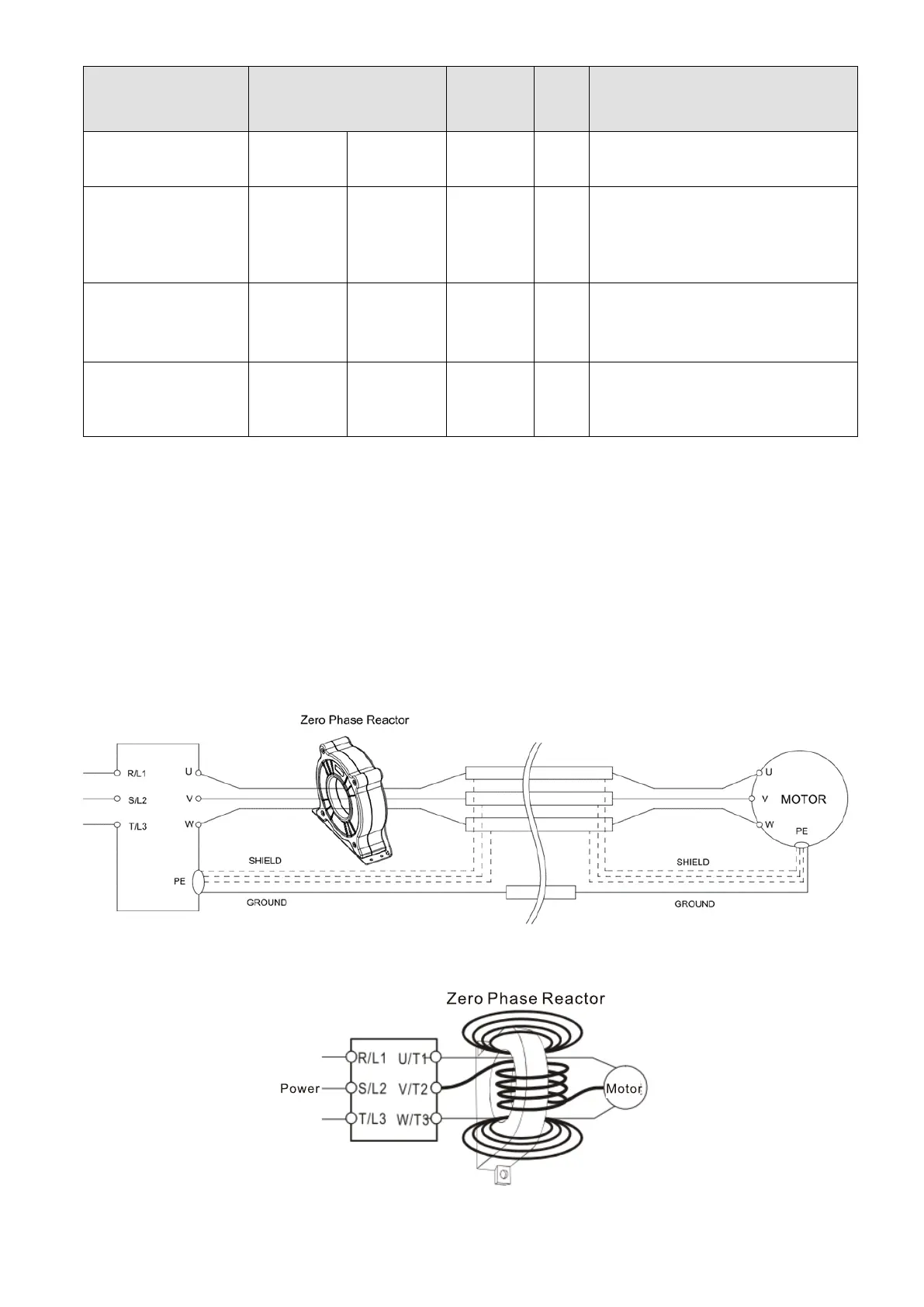

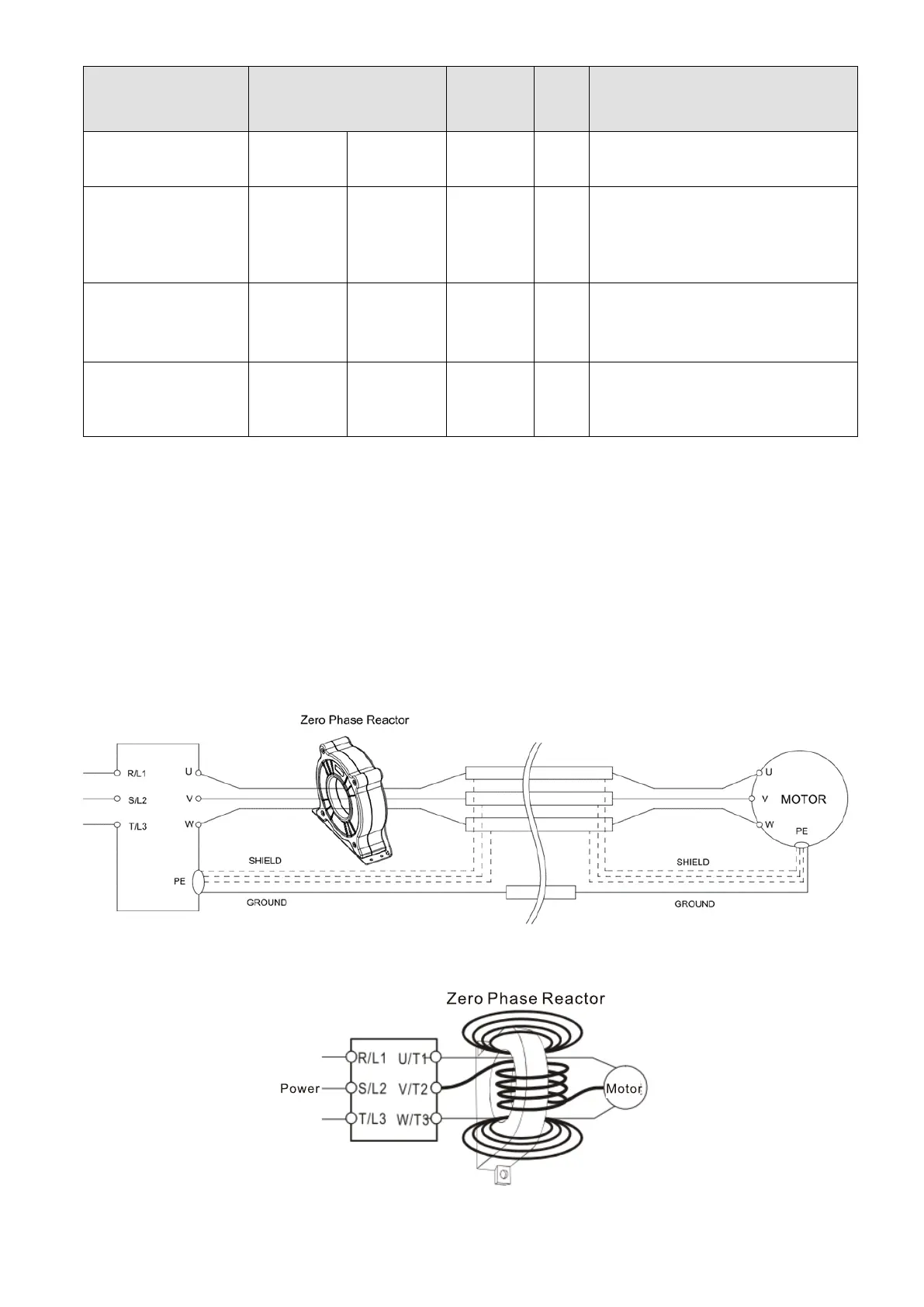

During installation, pass the cable through at least one zero phase reactor. Use a suitable cable type

(insulation class and wire section) so that the cable passes easily through the zero phase reactor. Do not

pass the grounding cable through the zero phase reactor; only pass the motor wire through the zero

phase reactor. With longer motor cables the zero-phase reactor can effectively reduce interference at the

motor output. Install the zero-phase reactor as close to the output of the drive as possible. Diagram A

shows the installation diagram for a single turn zero phase reactor. If the wire diameter allows several

turns, Diagram B shows the installation of a multi-turn zero phase reactor. The more turns, the better the

noise suppression effect.

Figure 6-32 Single turn wiring diagram for shielding wire with a zero phase reactor

Figure 6-33 Multi-turn zero phase reactor

Loading...

Loading...