Chapter 12 Description of Parameter SettingsMS300 (High Speed Model)

12-06-6

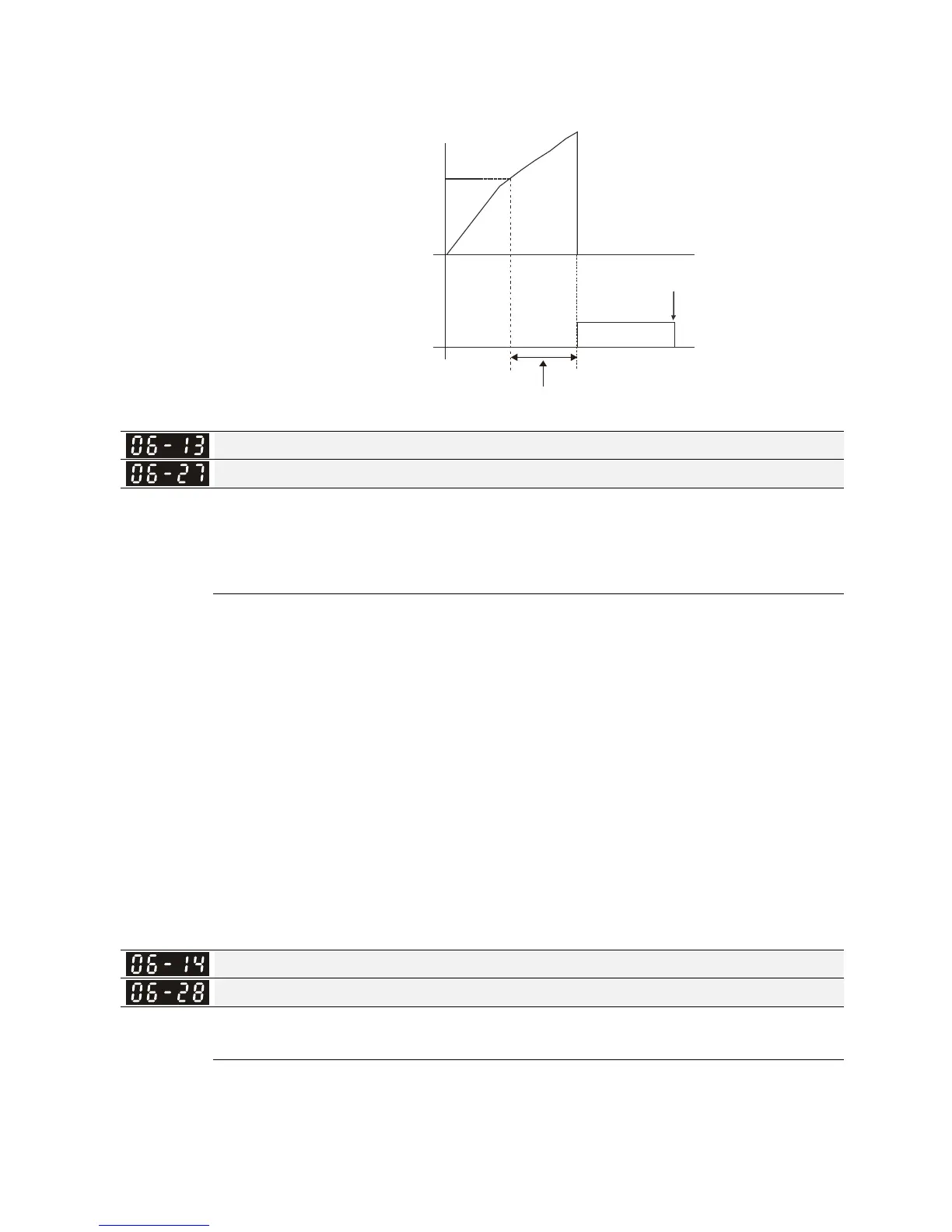

When Pr. 06-06 or Pr. 06-09 is set to 2 or 4, there will be ot1 / ot2 warning displayed and the drive

will stop running after over-torque detection. The drive will keep running after manually reset.

ON

Over-torque detection level

06-07 (06-10)

Output current

Multi-function output

terminal=7 or 8

Over-torque detection time

06-08 (06-11)

Manually reset

Electronic Thermal Relay Selection 1 (Motor 1)

Electronic Thermal Relay Selection 2 (Motor 2)

Factory Setting: 2

Settings 0: Inverter motor (with external forced cooling)

1: Standard motor (motor with fan on the shaft)

2: Disable

It is used to prevent self-cooled motor overheats under low speed. User can use electronic

thermal relay to limit the output power of drive.

Setting as 0 is suitable for Inverter motor (motor fan using independent power supply). For this

kind of motor, there is no significant

correlation between cooling capacity and motor speed.

Therefore the action of electronic thermal relay will remain stable in low speed to ensure the load

capability of motor in low speed.

Setting as 1 is suitable for standard motor (motor fan is fixed on the rotor shaft). For this kind of

motor, the cooling capacity is lower in low speed. Therefore the action of electronic thermal relay

will reduce the action time to ensure the life of motor.

When the power ON / OFF is switched frequently, if the power is switched OFF, the electronic

thermal relay protection will be reset. Therefore even setting as 0 or 1 may not protect the motor

well. If there are several motors connected to one drive, please install electronic thermal relay in

each motor respectively.

Electronic Thermal Relay Action Time 1 (Motor 1)

Electronic Thermal Relay Action Time 2 (Motor 2)

Factory Setting: 60.0

Settings 30.0~600.0 sec.

The parameter is set by 150 % of motor rated current and used with the setting of Pr. 06-14 and

Pr. 06-28 to prevent the motor from damage due to overheating. When it reaches the setting, the

drive will display “EoL1 / EoL2”, and the motor will be free running to stop.

Loading...

Loading...