TT-2000 Ticket Eater™ by Deltronic Labs February 2013

Blade Adjustment & Replacement

Stationary Blade Adjustment

The Ticket Eater blade is adjusted at the factory. As the blade wears, adjusting it so that

it is closer to the cutter will extend its life. To adjust the blade, follow these steps:

1. Make sure the POWER IS OFF and the cutter is not rotating.

2. Pull straight up to remove the cutter assembly from guide housing assembly

3. Set the cutter assembly on a spacer or the edge of your workbench so that you can

access the blade screws and turn the flywheel.

CAUTION: Even a dull blade is sharp enough to cut your fingers. Keep them

away from the cutter and the blade.

4. Use a 7/64 inch hex wrench to loosen the socket head attachment screws that hold

the stationary blade. Loosen them so that they can be turned with your bare

fingers, but do not remove them.

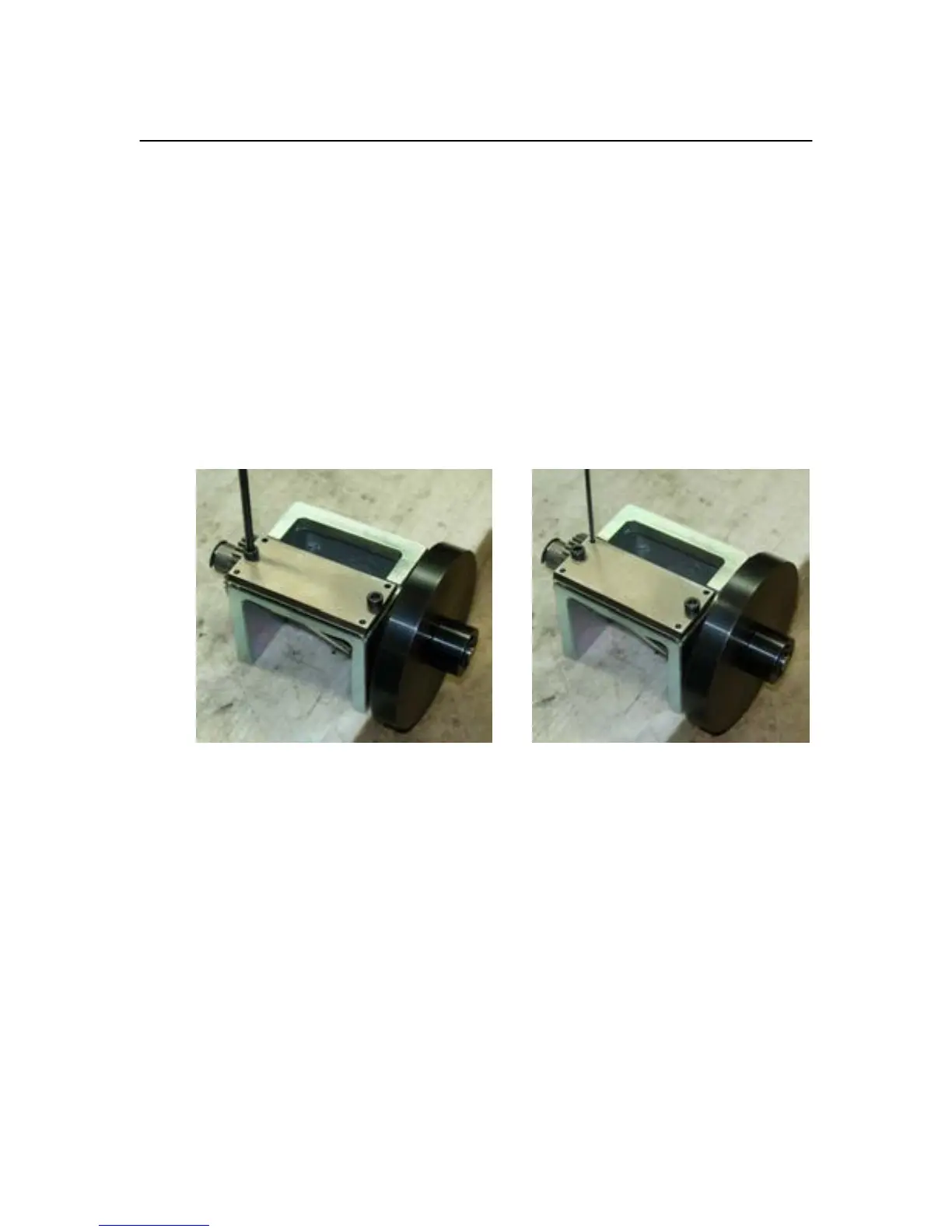

Socket Head Attachment Screw

Adjustment Set Screw

5. Insert a 1/16 inch hex wrench through the top clearance hole of the stationary

blade into the set screw.

6. Turning the set screw clockwise will move the blade closer to the cutter. Slowly

spin the flywheel while turning the set screw clockwise. As the blade nears the

cutter edge you will start to hear and feel the blade touch the cutter as you rotate

it. If you go too far the cutter will not turn freely. Adjust both the left and right

sides so that you get no contact and can see no light between the cutter and the

blade..

7. Slowly tighten the screws that hold the stationary blade while rotating the cutter

and checking the contact adjustment. As the screws are tightened they will pull

the blade away from the cutter. Use the adjustment screws to compensate.

8. Re-install the cutter assembly in the machine. Make sure that it is seated all the

way down so that its gear meshes correctly with the gear on the guide housing

assembly.

Loading...

Loading...