20

DEPA

®

Air Operated Diaphragm Pumps

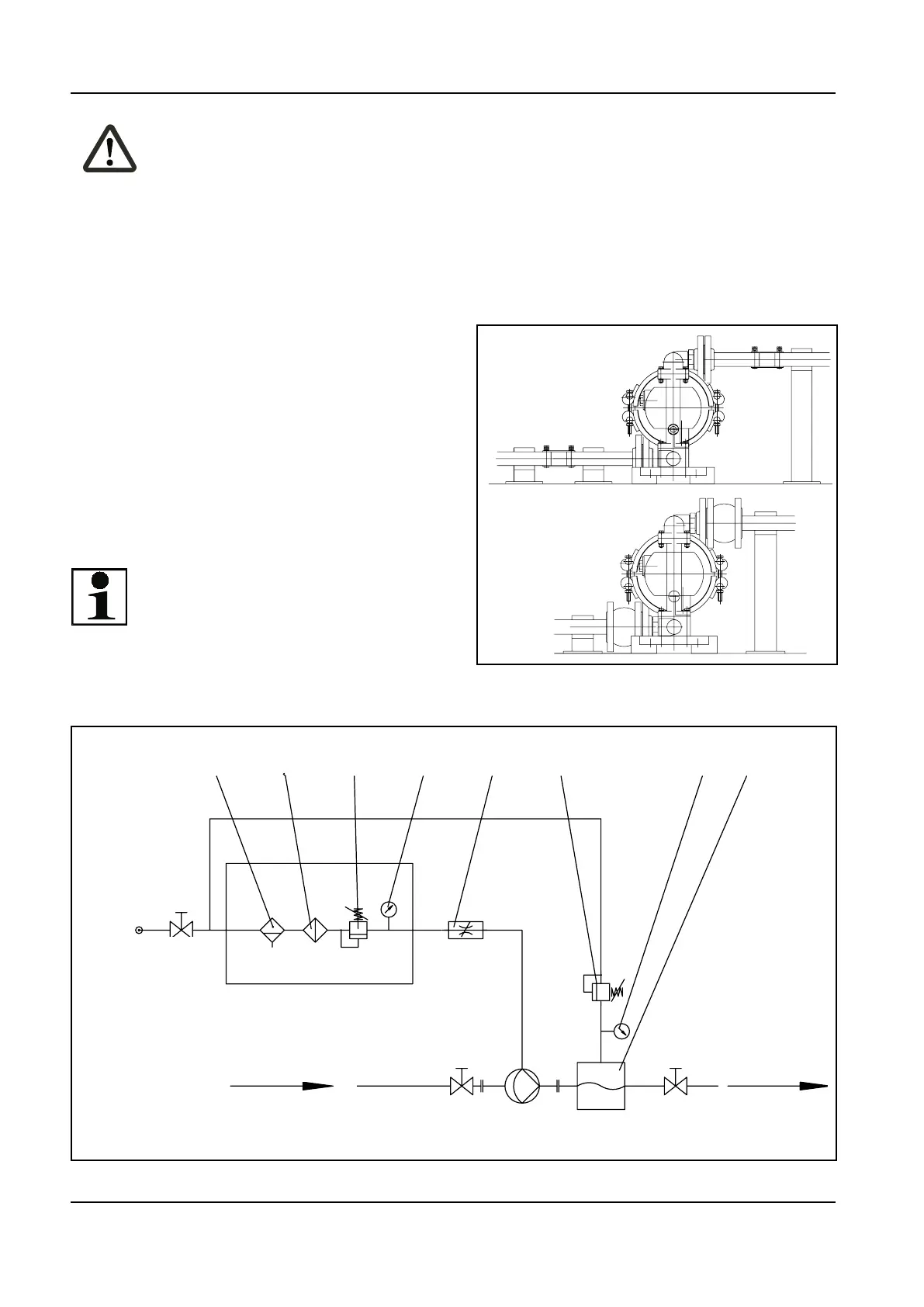

Fig. 3: Installation proposal for diaphragm pump

1

1

2

2

2

2

1. Compensators

2. Pipeline support

Pumping combustible liquids.

Experience has shown that

dangerous charges are not

likely at ow velocities > 7m/s

(TRGS 727).

The cross-section of the compressed

air supply must not be smaller then the

connection on the pump.

For simple removal of the pump a shut-

oelementeachmustbeinstalledinthe

suction and pressure sides.

■ The weight of the pipeline must be

taken up before the pump.

■

Elongation compensators must be

installed to compensate any elongation

of the pipes caused by temperature

increase.

Note:

It is recommended to

install flexible, shape and

pressure resistant hoses or

1

2

34

5

364

77

Luft-

versorgung

Einlass

Auslass

aktiver Pulsationsdämpfer

Nadelventil

Druckanzeige

Druckminderer

Filter

Abscheider

3

5

4

6

1

2

Saug- und druckseitige Absperrorgane

7

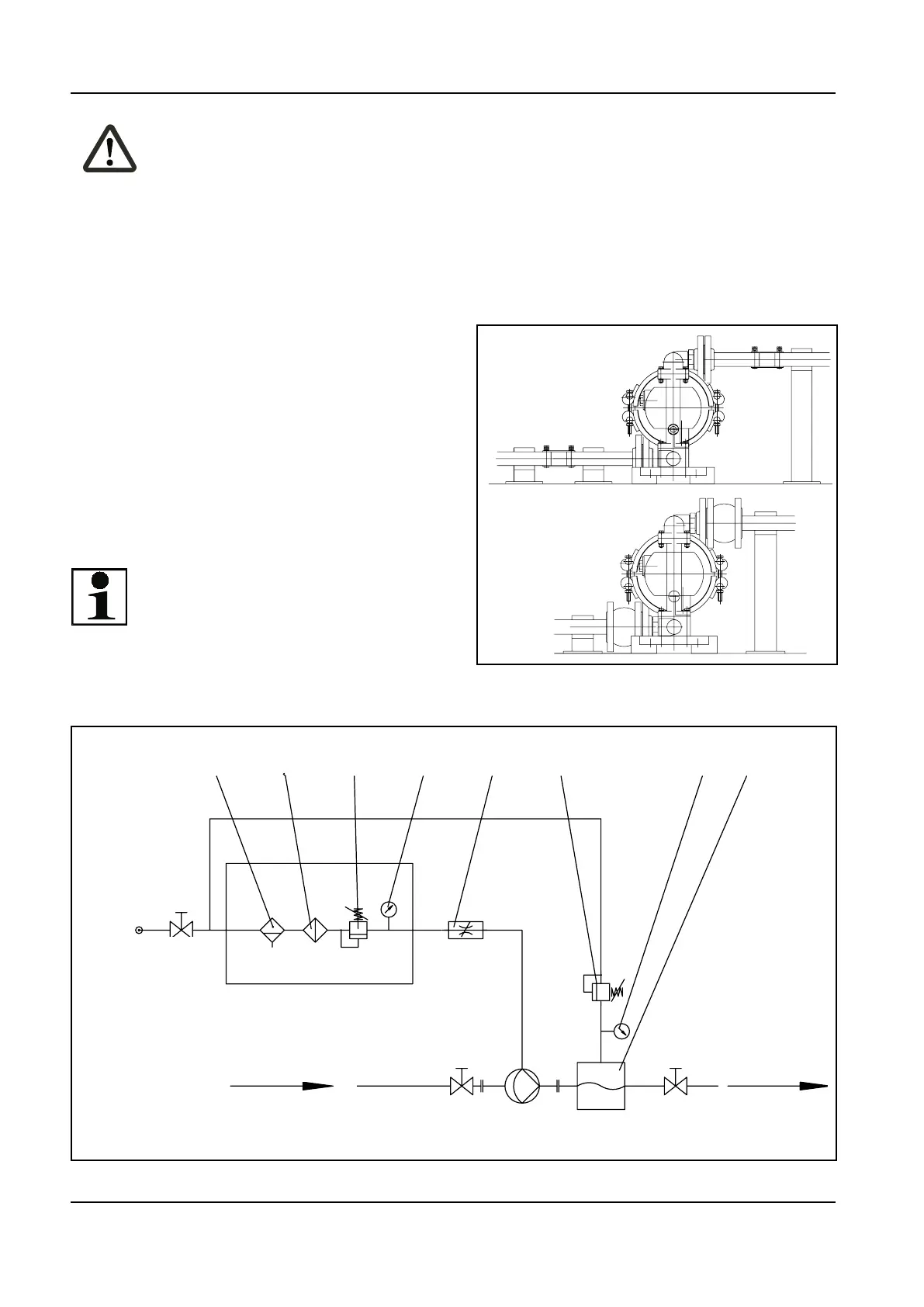

Inlet

Outlet

1. Water separator

2. Filter

3. Pressure reducer

4. Pressure gauge

5. Needle valve

6. Active pulsation dampener

7. Shut-off elements on suction and

pressure side

Fig. 4: Example of a pump installation

Air

supply

compensators at the suction

and pressure ports of the pump

(Fig. 3). This will prevent the

transfer of pulsation shocks

into the pump.

3.3 Placement and possible

installations of the pump

Loading...

Loading...