29

DEPA

®

Air Operated Diaphragm Pumps

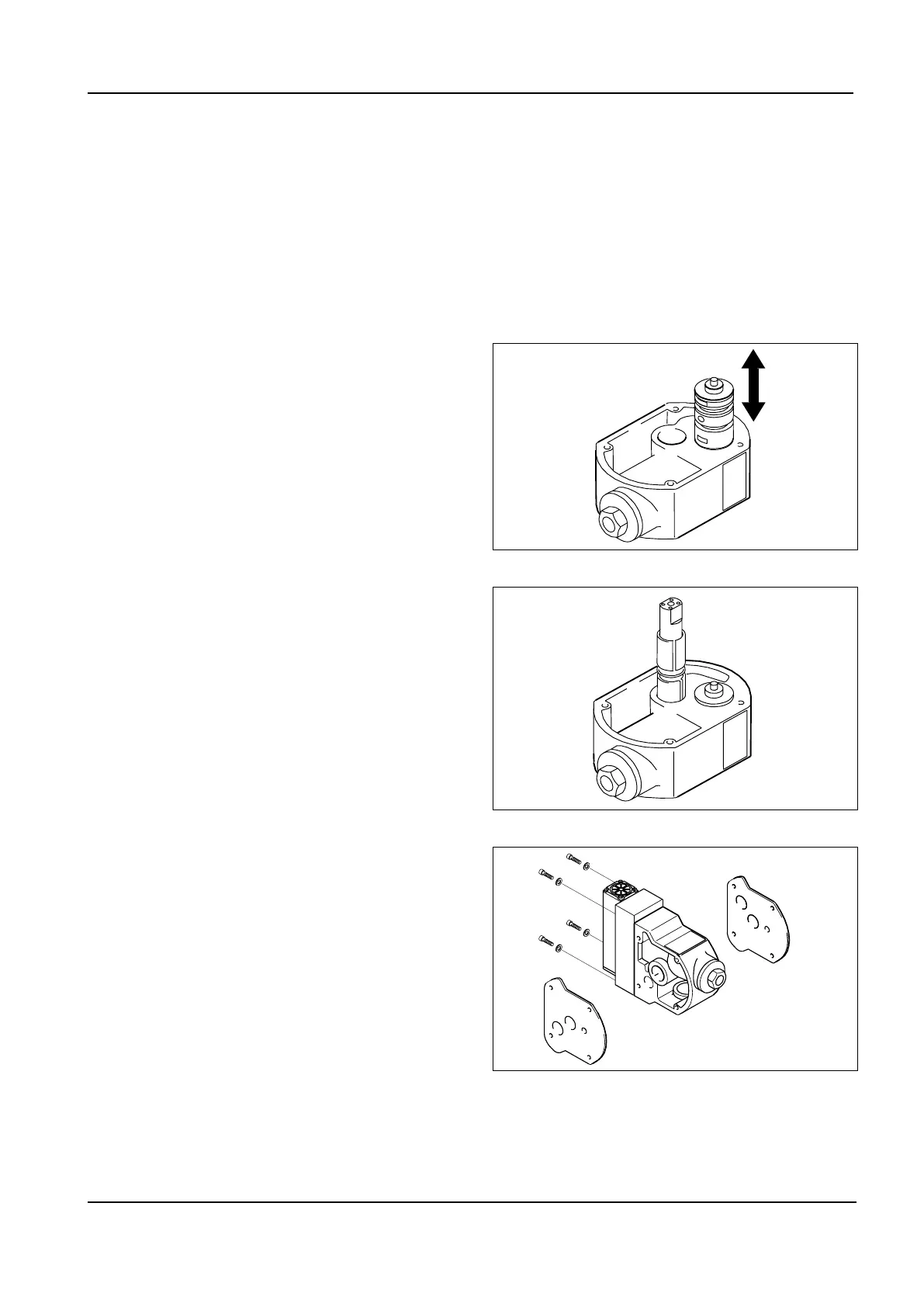

Fig. 17: Assembly of piston rod

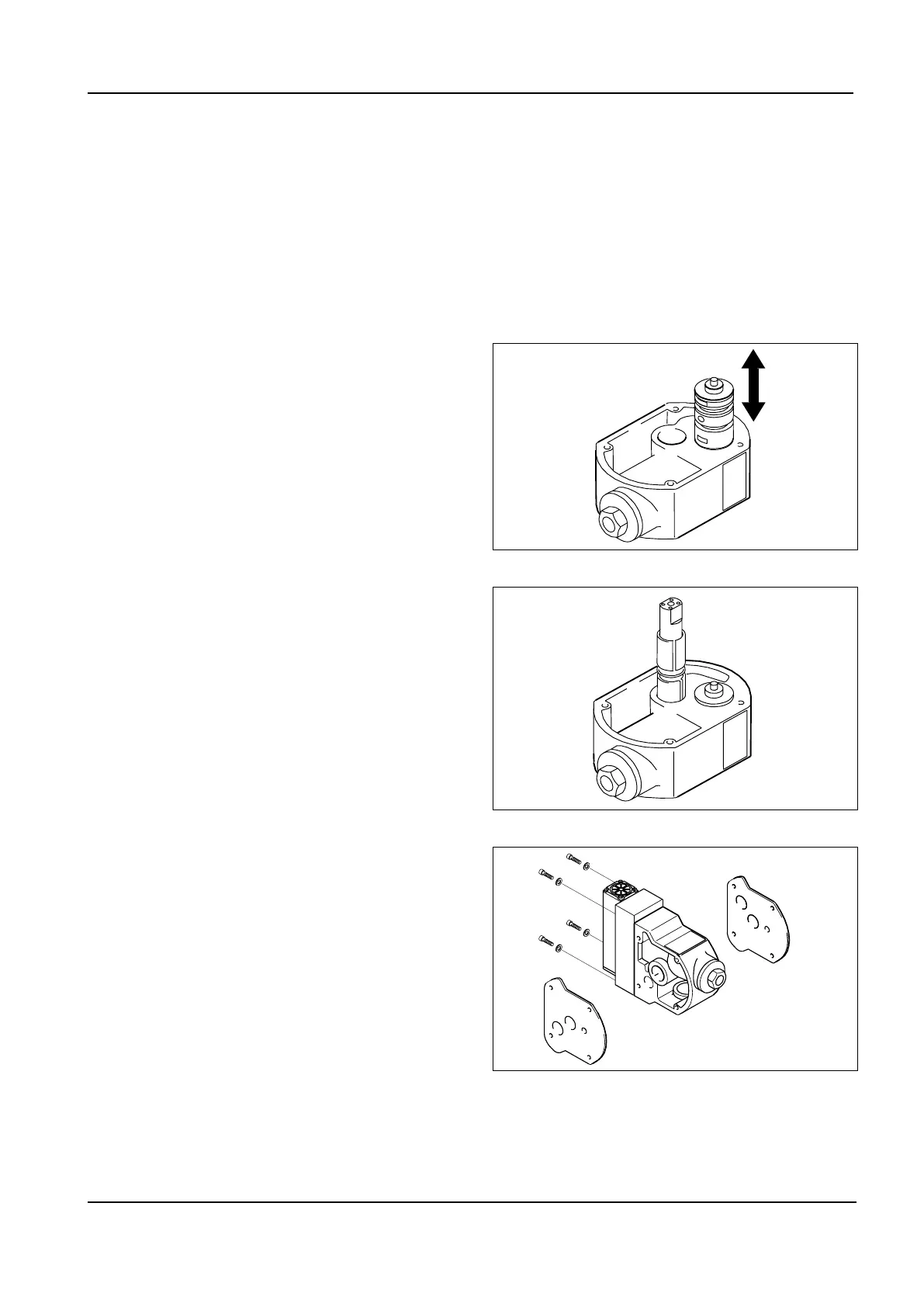

Fig. 16: Assembly of internal control valve

Fig. 18: Assembly of external control valve

ValveseatsforseriesPM(onlyone

O-ring or no O-ring) must be completely

replaced after each disassembly of the

ports.

On plastic pumps from DL25 the O-rings

in the outer diaphragm plate must be re-

placed after each disassembly.

■Assemble the ball lifter (optional acces-

sory), install a pressure-side valve seat

in the ball lifter

■Assemble new valve balls.

■

Tighten the fastening screws for suc-

tion and pressure ports with the correct

torque.

■

Pumps of series DH-TP/TPL are gener-

ally equipped with DEPA nopped E4

®

compound diaphragms. Installation of

the diaphragm takes place by means

ofindexingdiscandsetscrew,without

the diaphragm plate: After the set screw

is threaded, the diaphragm is to be

screwed onto the plunger and tightened

by hand.

5.3.1.4 Replacement of the internal

control valve

■Procedure as described under 5.3.1.

■

Unscrew the air chambers from the

central block (only on metal pumps,

exception:DBdiaphragmpumps,DH)

(Fig. 12).

■

Press the air control valve out of the

central block.

■

The air control valve is replaced as a

complete unit (Fig. 16).

■

To install the plain bearing bushings

and seal ring, we recommend using the

piston rod for guidance (see Fig. 17).

■

In contrast to the assembly instructions

for bearing bushings of pump series

DL25-DL80,whicharettedwithtwo

bearing bushings, the procedure for

pump size DL15 withkits single bearing

bushingisslightlydierent.

The bearing bushing has two grooves

to take up the outer O-rings. In order to

Loading...

Loading...