43

DEPA

®

Air Operated Diaphragm Pumps

wall clearances and flow velocities. It

is therefore essential to monitor the

pump during these processes. See

TRGS 727.

When using nopped E4

®

PTFE com-

pound diaphragms and PTFE dia-

phragms, in each case size 80, mi-

crofilters in the pump inlet are not

permitted. Multiphase insulating liq-

uids must not be pumped with DEPA

nopped E4

®

compound diaphragms

as well as PTFE diaphragms and PTFE

valve balls, in each case size 80.

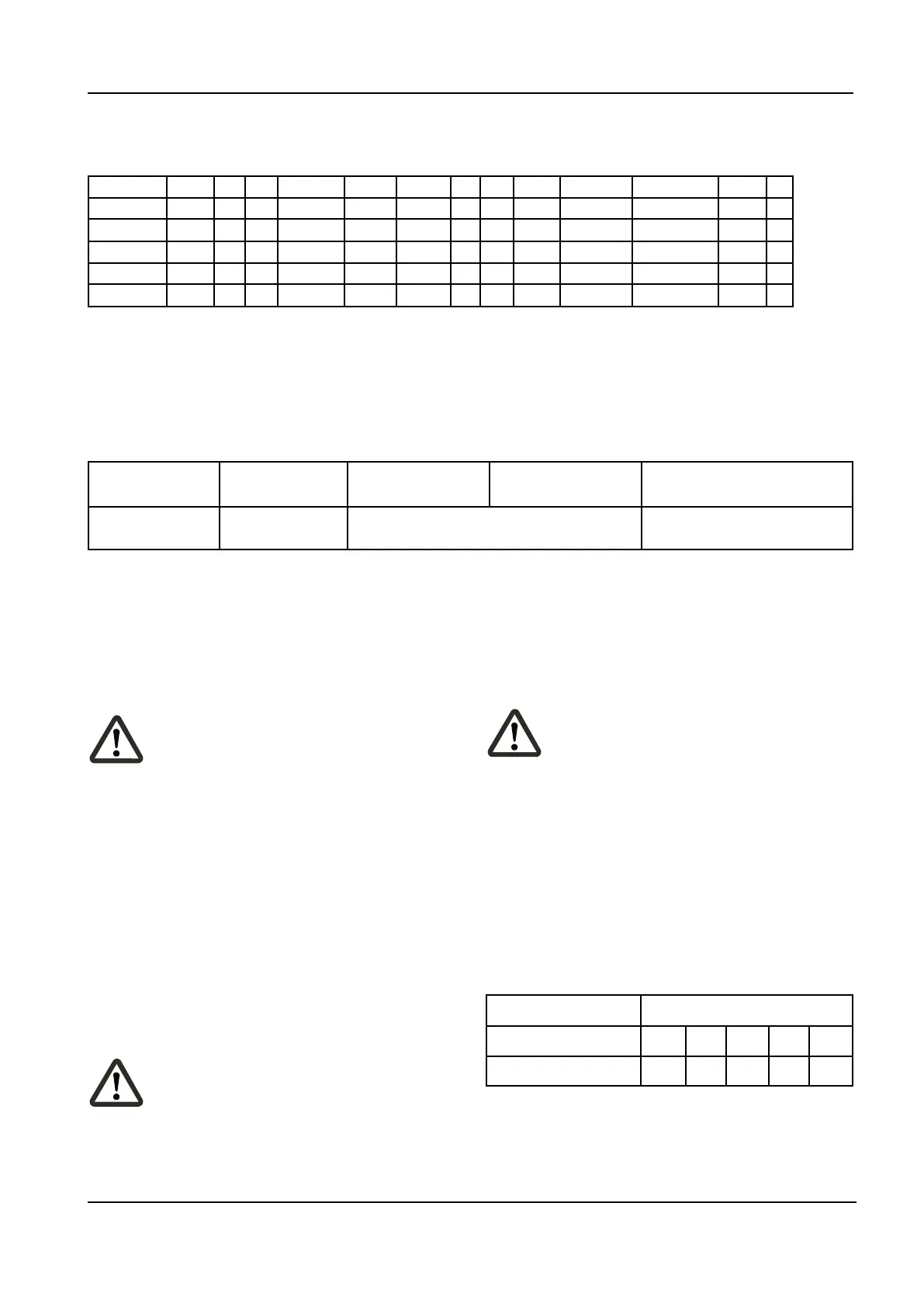

In order to ensure correct functioning of the pump

themaximumpumpedmediumparticlesizeslisted

inthefollowingtablemustnotbeexceeded.

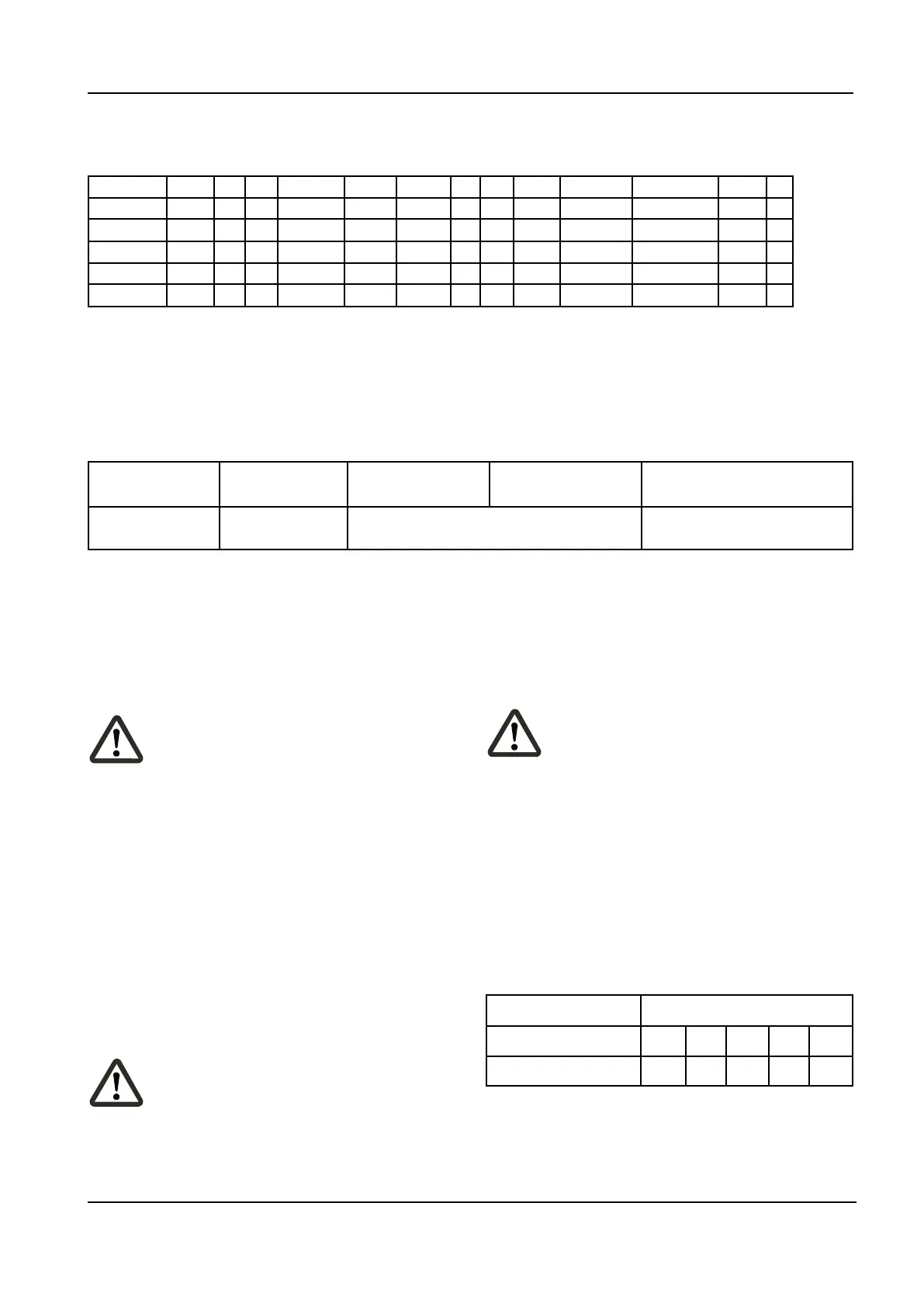

9.1 Pump weights in kg (for combinations with stainless steel seats or balls with core increase

the weight of the pump)

10.0 Category 1 and 2 equipment intended for use in potentially explosive environments

10.1 Equipment category 1

10.1.1 Design, housing and materials

*Max.operatingpressureforDHxx-SSoutsidezone0is8.6bar

Table 5 Materials and pump types

Material type

Pump type

code

Min (°C) Max (°C)

Max. operating pressure

(bar)

Stainless steel

DHxxSS

Temperature range is limited by interior

ttings

7 *

Table6:max.particlesizes

Pump size

Pump type DH SS

15 25 40 50 80

Particle size (mm)

5 8 11 13 18

10.1.2 Usage instructions

When using the pump in zone 0, only media with

a minimum conductivity of 10,000 pS/m (0.01

μS/m)maybepumped.

If substances penetrate the sealed

air valve through defective dia-

phragms (diaphragm rupture), pump

operation must be stopped immedi-

ately.

Inexplosiveenvironments,thepumpmustbe

monitoredinthecaseofincompletemedialling

(e.g.suctionandsnoremode),andifthereisuid

leakageattheexhaustoutlet(e.g.muer),the

pumpmustbeswitchedoandonlyputbackinto

operation further to being checked (see Section

6.0).

Themuerpermanentlydischargesrelieved

compressed air. This air can whirl up dust and

thusgenerateanexplosiveatmosphere.

When using the pump in zone 0,

start-up and pumping out proce-

dures are limited to a duration of <

0.5 minutes so that critical discharg-

es do not occur in the pump de-

pending on the size, corresponding

Pump size

DH-FA CA CX DL- SA/SF DH- SA DH- SS SX PM PP/PL DH-TP/TPL DL-SL/SU/UE DH-UE DB

15 2 - - 4,8 7 9,5 - 6 5 11,2 9 10 -

25 8,2 13 16 14 12 17 17 8,4 10 27 21 27 35

40 12 23 24 29 20 24 31 13 17 45,8 30 33 49

50 35,4 50 51 51 42 51 53 - 37 89 57 73 90

80 55 100 105 119 73 85 125 - 75 - 94 - -

Loading...

Loading...