25

DEPA

®

Air Operated Diaphragm Pumps

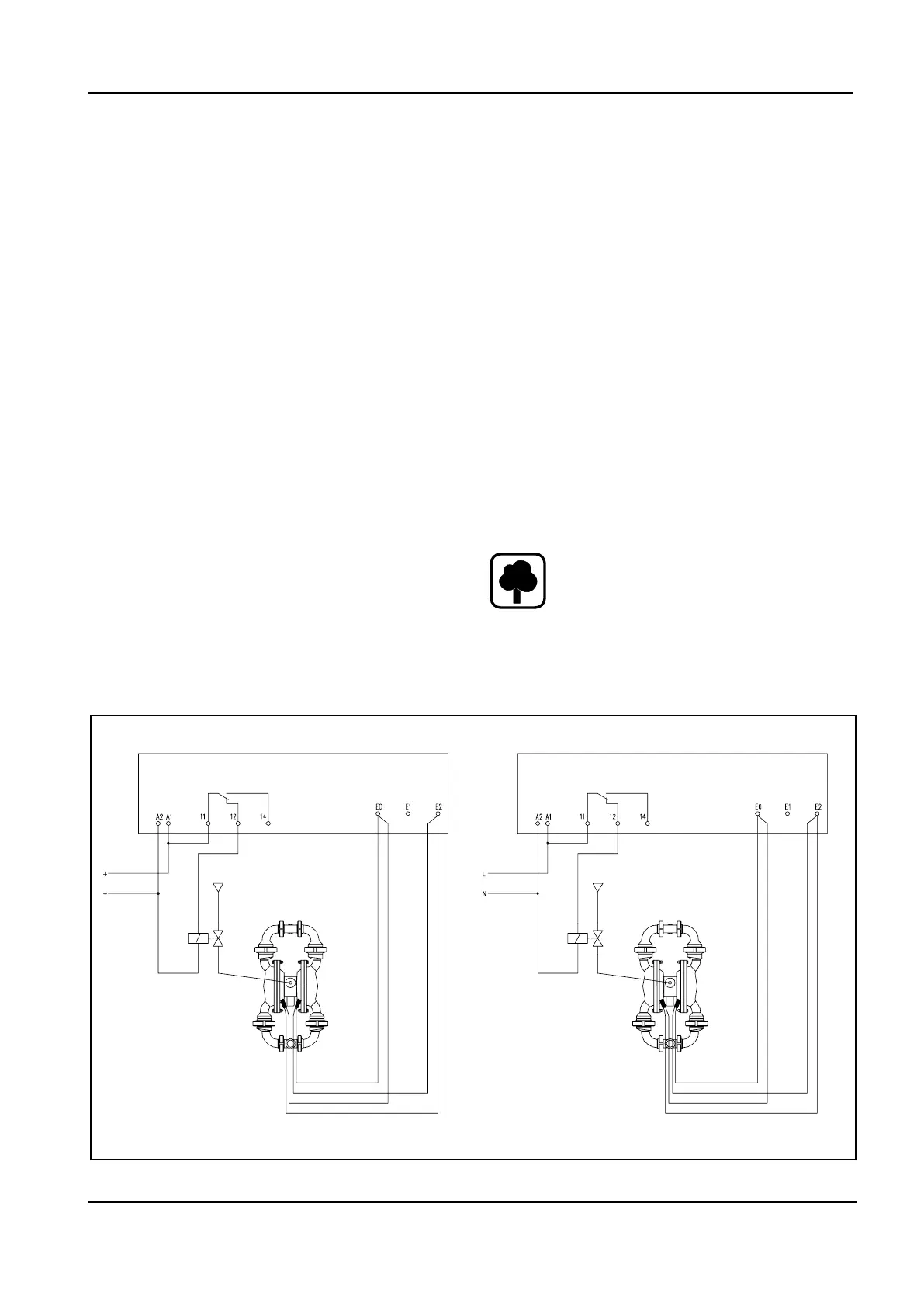

4.10 Diaphragm break sensors and

shut-down in the event of leaks

When using diaphragm break sensors, the

air supply may be interrupted if there is a

leak. For electrical connections please refer

to the wiring diagram on page 25 (Fig. 6.

4.11 Pulsation damping

Air operated diaphragm pumps are dou-

ble-acting, oscillating displacement pumps

andthusgenerateapulsatingow.Formin-

imizing this pulsationing we recommend the

use of pulsation dampeners. There are var-

ious designs available, active and passive,

made of metal or plastic, with and without

diaphragmsandinseveraldierentsizes.

Depending on the prevailing pressure condi-

tions they must be manually or automatically

adjusted in-situ. See Fig. 4 and Section 7.

4.12 Downtimes

After pumping product with solids, chem-

icals or oils the pump chambers must be

thoroughlyushedbeforeshuttingdown.

This prevents the settlement of soilds or

chemical attacks and thus the destruction of

the diaphragms when restarting.

4.13 Taking out of service

Thepumpstopswhencuttingotheair

supply. Since the valve balls in suction and

pressure sides act as non-return valves, the

rising part of the pressure line will always

remainlledwithproduct.Whendisassem-

bling the pump care must be taken, as the

pumpmaystillbelledwithproduct.The

pump itself can be partly emptied through

the plugs on the sides of the pump (option-

al).

4.14 Waste disposal after expiry of

the expected service life

The metal components used,

such as aluminium, grey cast

iron, high-grade steel and steel

can be returned for recycling.

Plastic parts cannot be reused

and must be disposed of as

residual waste.

Fig. 6: Wiring diagram leakage sensors

Air supply

Voltage

supply

24VDC

Diaphragm monitoring

Diaphragm monitoring

Voltage

supply

Air supply

Housing width 22.5 mm - suitable for

mountingon35mmopenboxsectionrail

Housing width 22.5 mm - suitable for

mountingon35mmopenboxsectionrail

Wiring diagram

115VAC

(230VAC)

Loading...

Loading...