15

MG6-OLVERT-3B Rev. 0 12/30/99

Belt - Replacement

(Refer to the Outfit Parts Manual for replacement

belt part number.)

SERIOUS INJURY OR DAMAGE MAY OCCUR IF

PARTS OF THE BODY OR LOOSE ITEMS GET

CAUGHT IN MOVING PARTS. NEVER OPERATE

THE OUTFIT WITH THE BELT GUARD REMOVED.

THE BELT GUARD SHOULD BE REMOVED ONLY

WHEN THE COMPRESSOR POWER IS DISCON-

NECTED.

1. Turn compressor off, lock out the power supply, and relieve

all air pressure from the tank.

2. Remove the clips, screws, and outer panel of belt guard.

3. Loosen the motor mounting hardware and slide the motor

toward the compressor.

4. Remove the belt and replace with a new one.

Safety Valve - Inspection and Replacement

IF THE SAFETY VALVE DOES NOT WORK PROP-

ERLY, OVER-PRESSURIZATION MAY OCCUR

CAUSING AIR TANK RUPTURE OR EXPLOSION.

OCCASIONALLY PULL THE RING ON THE SAFETY

VALVE TO MAKE SURE THAT THE SAFETY VALVE

OPERATES FREELY. IF THE VALVE IS STUCK OR

DOES NOT OPERATE SMOOTHLY, IT MUST BE

REPLACED WITH A VALVE HAVING THE SAME

PRESSURE RATING.

1. Remove and lock out power from the compressor. Release

any air pressure from the air tank.

2. Remove safety valve and replace with valve of the same

pressure rating.

3. Apply thread sealant to new safety valve and tighten. DO

NOT OVERTIGHTEN.

SAFETY VALVE

SERVICE INSTRUCTIONS (cont'd)

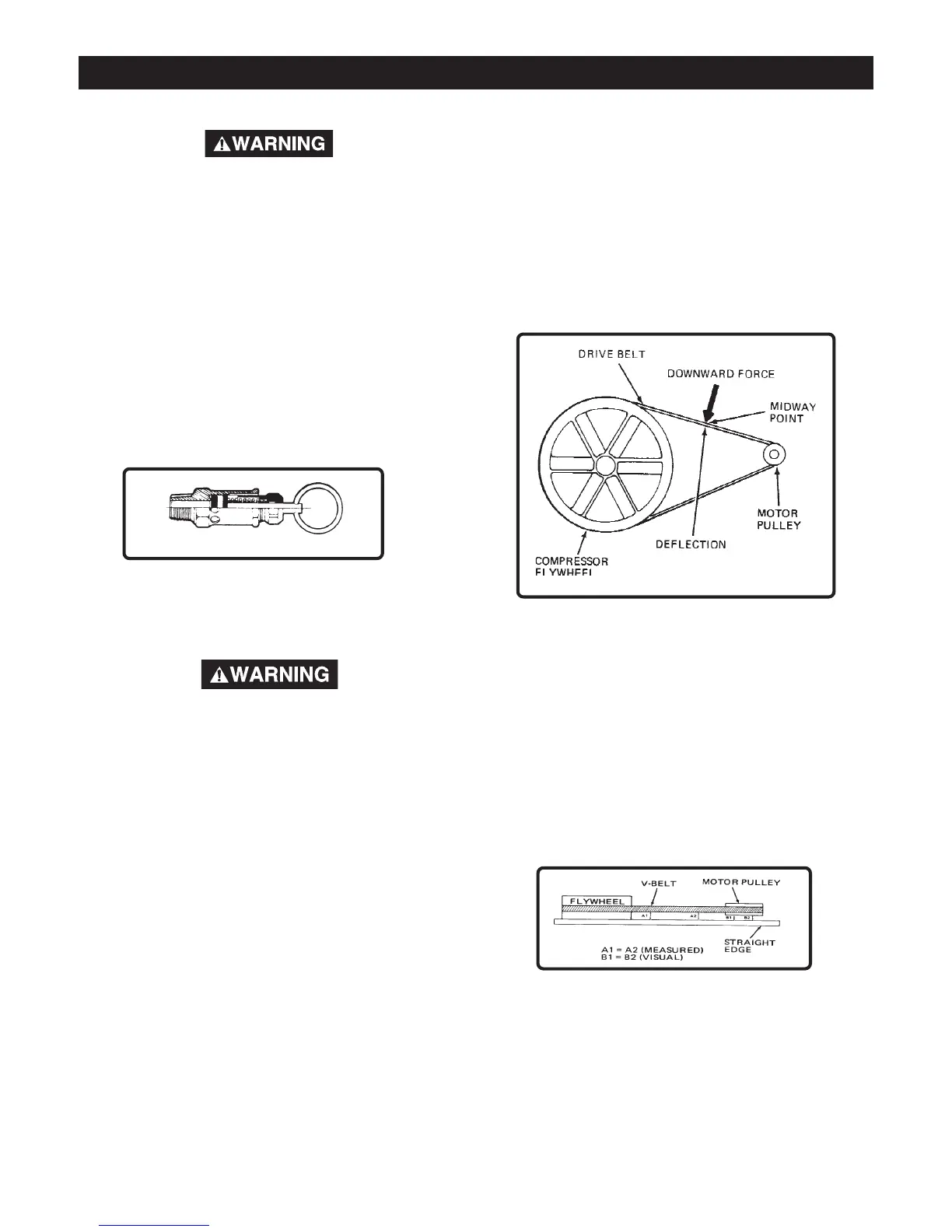

Adjusting Belt Tension

Adjust belt tension as described below:

1. Slide motor away from compressor until desired tension is

obtained.

The belt should deflect 3/16" at midway between the pulley

and the flywheel when a 5 pound weight is applied at the

midway point.

2. Tighten two outside cap screws enough to hold the motor

in place for checking pulley and flywheel alignment.

3. Once aligned, tighten all four cap screws. See Outfit Parts

Manual for correct torque specifications.

Motor Pulley and Flywheel Alignment

1. Place a straight edge along the outside face of the compres-

sor flywheel to check alignment of V-belt grooves. (See

figure below for proper alignment.)

2. If the belt grooves aren't aligned, continue with step 3 of this

procedure. If the belt grooves are aligned, continue with step

4 of this procedure.

3. Loosen pulley set screw and move the pulley until it is in

proper alignment.

4. Tighten pulley set screw. See Outfit Parts Manual for correct

torque specifications.

5. Reinstall belt guard.

Loading...

Loading...