17- ENG

D26805

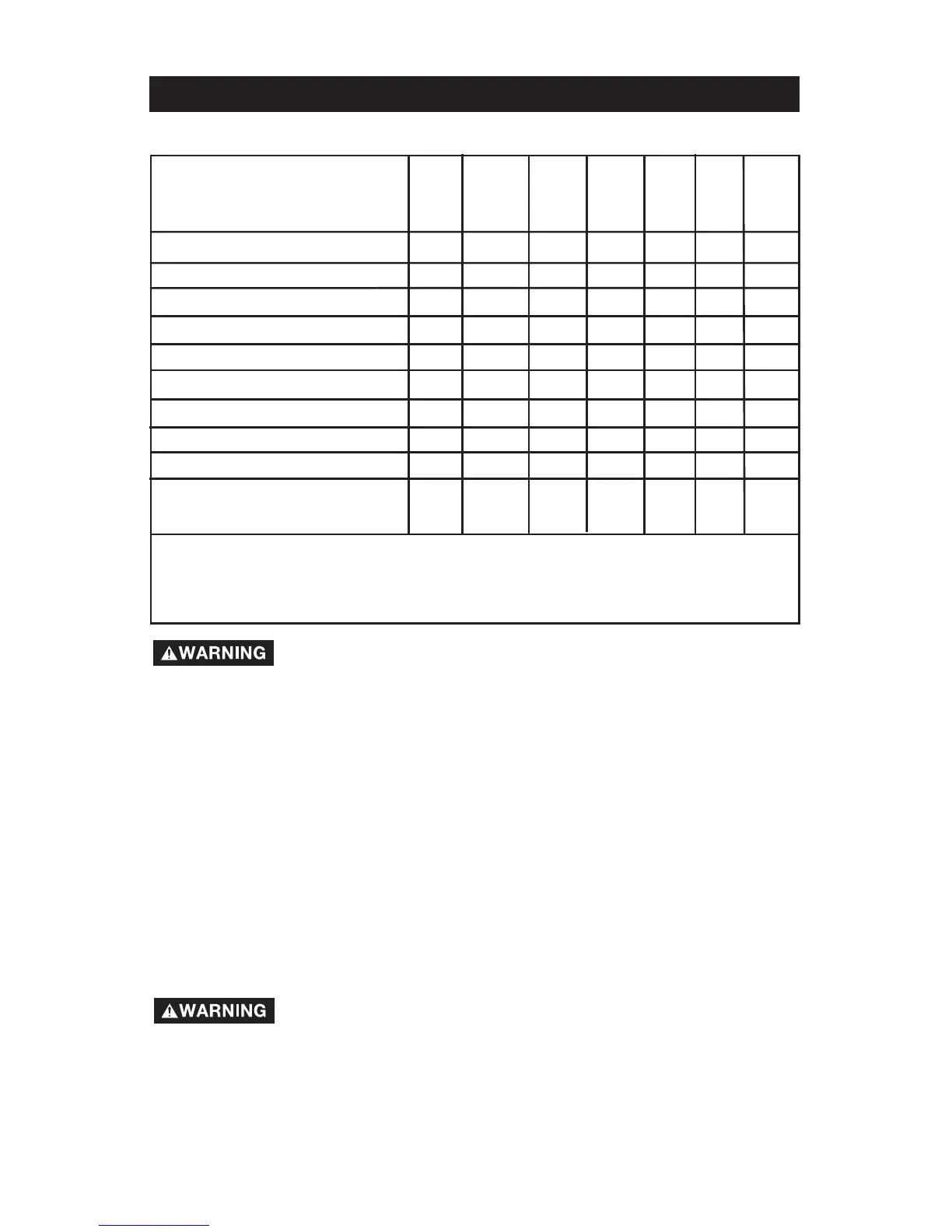

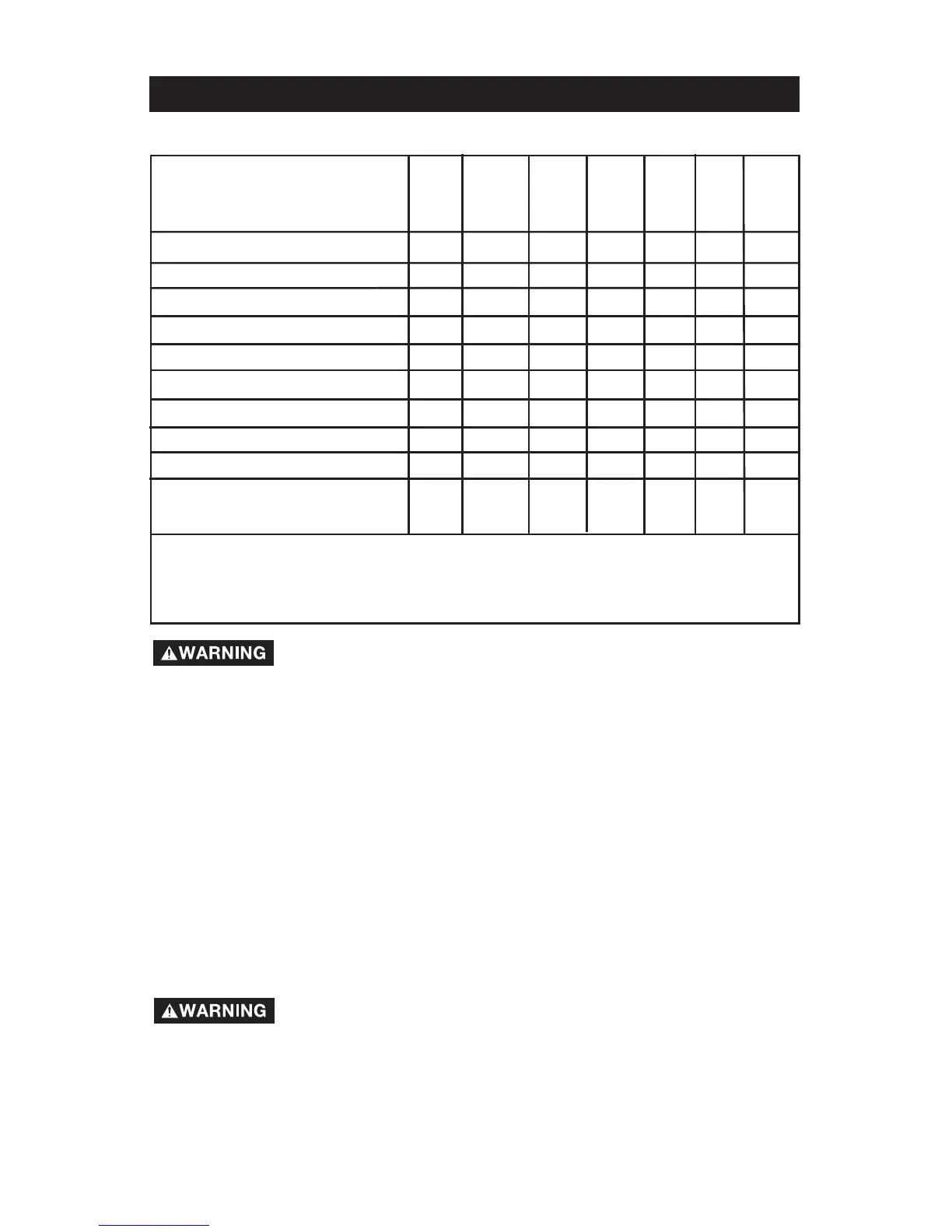

MAINTENANCE

Customer Responsibilities

Daily or

after

each

use

Before

each

use

●

●

●

●

Every

8

hours

Every

40

hours

Every

100

hours

Yearly

Every

160

hours

●

●

1

1- more frequent in dusty or humid conditions

Check Safety Valve

Drain Tank

Oil Leaks

Check Pump Oil

Change Pump Oil

Air Filter

NOTE: See "Operation"section for the location of controls.

To ensure efficient operation and longer life of the air compressor outfit, a

routine maintenance schedule should be prepared and followed. The following

routine maintenance schedule is geared to an outfit in a normal working

environment operating on a daily basis. If necessary, the schedule should be

modified to suit the conditions under which your compressor is used. The

modifications will depend upon the hours of operation and the working

environment. Compressor units in an extremely dirty and/or hostile environment

will require a greater frequency of all maintenance checks.

During maintenance, you could be exposed to compressed

air or moving parts. Personal injuries can occur. Before

doing any maintenance or repair, disconnect the spark plug wire to prevent

accidental starting, and relieve air tank pressure. Never operate the

compressor with the belt guard removed.

To Check Safety Valve

If the safety valve does not work properly, over-

pressurization may occur, causing air tank rupture or an

explosion.

1. Before starting compressor, pull the ring on the safety valve to make sure

that the safety valve operates freely. If the valve is stuck or does not

operate smoothly, it must be replaced with the same type of valve.

●

●

●

●

Drive Belt -Condition

Motor Pulley/Flywheel alignment

Air compressor pump intake

and exhaust valves

Unusual Noise and/or Vibration

Consult the Engine Owners Manual for the manufacturer's recommendations

for any and all engine maintenance.

Loading...

Loading...