18- ENG

D26805

Air Filter - Inspection and Replacement

Hot surfaces. Risk of burn. Compressor heads are

exposed when filter cover is removed. Allow compressor

to cool prior to servicing.

Keep the air filter clean at all times. Do not operate the air

compressor with the air filter removed.

A dirty air filter will not allow the compressor pump to operate at full

capacity. Before using the compressor pump, check the air filter to make

sure it is clean and in place.

Oil

Drain tank to release air pressure before removing the oil

fill cap or oil drain plug.

Checking

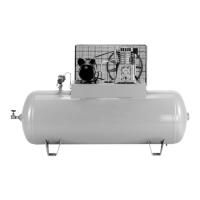

1. Remove the oil fill plug (A). The oil level should be even

with the top of the fill hole and no lower than 6 threads

from the top of fill hole.

2. If needed, slowly add oil until it reaches the top of fill hole.

NOTE: Use an oil specifically formulated for use in an air

compressor, such as Sears 9-16426 air compressor oil.

Changing

1. Remove the oil fill plug (A).

2. Remove the oil drain plug (B) and drain oil into a suitable container.

3. Replace the oil drain plug (B) and tighten securely

4. Slowly fill crankcase to the top of the fill hole. Crankcase capacity is 16

fluid ounces (473.2 ml).

A

B

To Drain Tank

1. Push down and hold engine stop lever until engine shuts off.

2. Remove the air tool or accessory.

3. Pull ring on safety valve allowing air to bleed from the tank until tank

pressure is approximately 20 psi. Release safety valve ring.

4. Drain water from air tank by opening drain valve (counter-clockwise) on

bottom of tank.

Water will condense in the air tank. If not drained, water

will corrode and weaken the air tank causing a risk of air

tank rupture.

5. After the water has been drained, close the drain valve (clockwise). The air

compressor can now be stored.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be

removed, cleaned, then reinstalled.

Overfilling with oil will cause premature compressor

failure. Do not overfill.

5. Replace oil fill plug (A) and tighten securely.

Loading...

Loading...