21- ENG

D26805

Pulley and Flywheel - Alignment

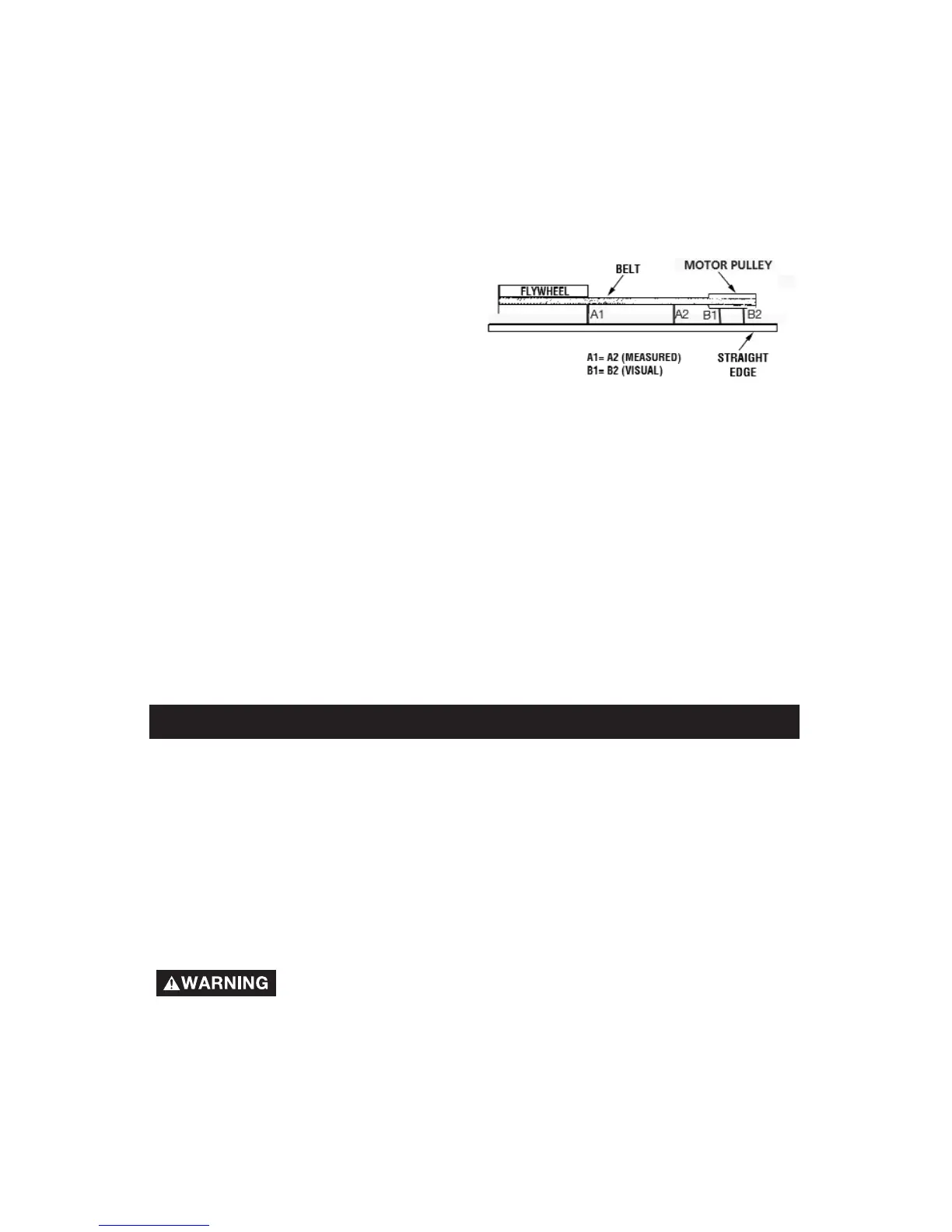

The air compressor flywheel and engine pulley must be in-line (in the same

plane) within 1/16" to assure belt retention within flywheel belt grooves. To

check alignment, perform the following steps:

1. Disconnect the spark plug wire on the engine and release all air tank

pressure.

2. Remove belt guard.

3. Place a straightedge against the

outside of the flywheel and the

engine drive pulley. Refer to Figure as

required.

4. Measure the distance between the

edge of the belt and the straightedge

at points A1 and A2 in Figure. The

difference between measurements

should be no more than 1/16".

5. If the difference is greater or less than 1/16", loosen the setscrew holding

the engine drive pulley to the shaft and adjust the pulley's position on the

shaft until the A1 and A2 measurements are within 1/16" of each other.

6. Tighten the engine drive pulley setscrew to 70-80 in.-lbs.

7. Visually inspect the engine drive pulley to verify that it is perpendicular to the

drive motor shaft. Points B1 and B2 of Figure should appear to be

equal. If they are not, loosen the setscrew of the engine drive pulley and

equalize B1 and B2, using care not to disturb the belt alignment performed

in step 2.

8. Retighten the engine drive pulley setscrew to 70-80 in.-lbs.

9. Reinstall belt guard.

10. Reconnect spark plug wire to spark plug on engine.

STORAGE

Before you store the air compressor, make sure you do the following:

1. Review the "Maintenance" section on the preceding pages and perform

scheduled maintenance as necessary.

2. Review the "Engine Manufacturer's Operating and Maintenance

Instructions".

3. Remove the air tool or accessory.

4. Pull ring on safety valve allowing air to bleed from the tank until tank

pressure is approximately 20 psi. Release safety valve ring.

5. Drain water from air tank by opening drain valve on bottom of tank.

Water will condense in the air tank. If not drained, water

will corrode and weaken the air tank causing a risk of air

tank rupture.

6. After the water has been drained, close the drain or drain valve.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be

removed, cleaned, then reinstalled.

7. Wind air hose around hose wrap and secure in place.

Store the air compressor in a clean and dry location.

Loading...

Loading...