Page 13SB-2-855-B

PARTS REPLACEMENT/MAINTENANCE

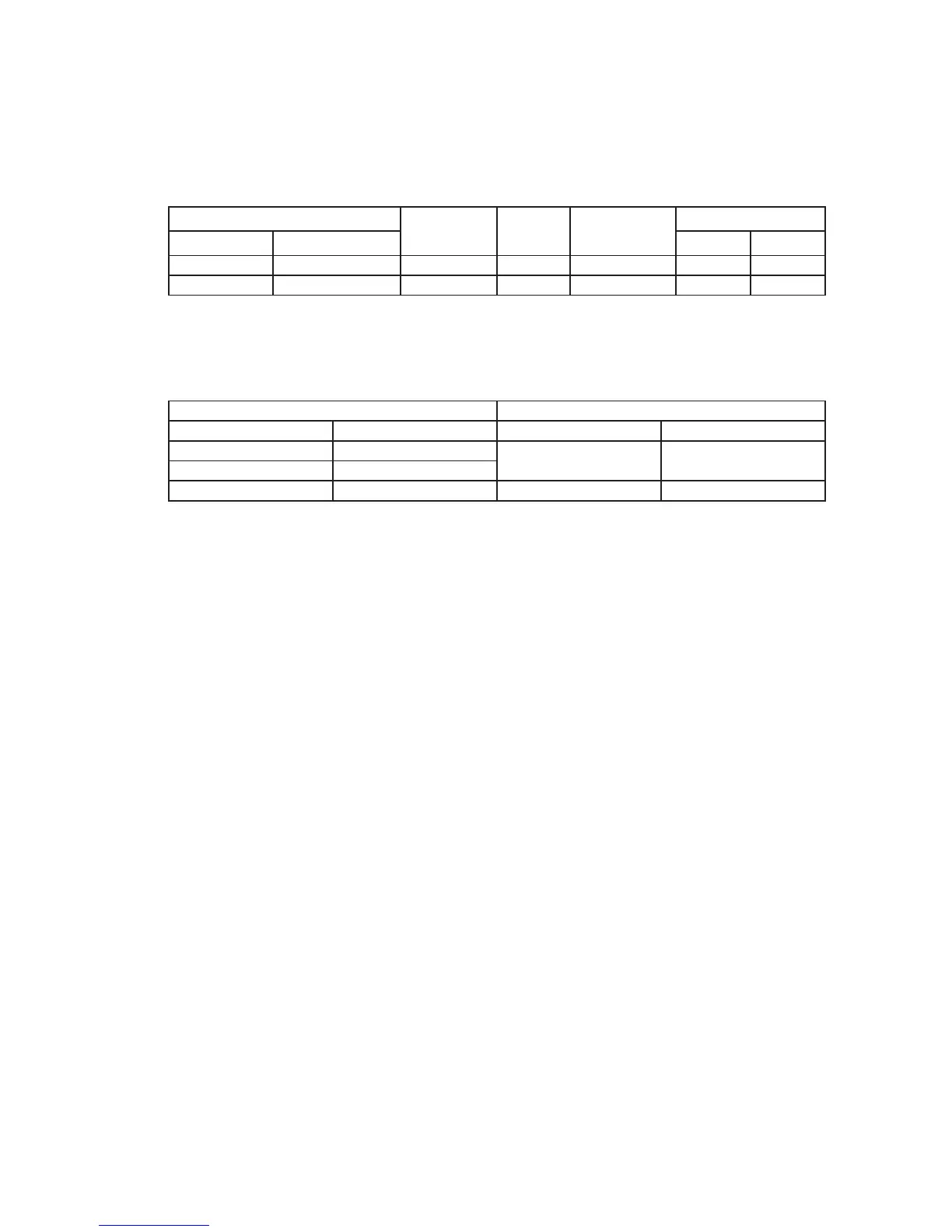

CHART 1 – AIR CAPS

AIR CAP & RING

TECHNOLOGY

MARKING

ON

AIR CAP

RECOMMENDED

INLET

PRESSURE

AIR FLOW

COMPUTER NO. PART NO. (L/min) (CFM)

803296 SRIPRO-101-HS1 HVLP HS1 29.0 psi (2.0 bar) 135 4.8

803297 SRIPRO-100-TS1 TRANS-TECH

®

TS1 29.0 psi (2.0 bar) 100 3.5

NOTE: When removing air cap from retaining ring, don’t remove the Slip Ring (2) or Retaining Ring Seal (5) from the

Retaining Ring. Damage to the parts may occur. Slip ring and Retaining Ring seal are not available as replacements.

Simply wipe parts clean and reassemble with new or clean air cap.

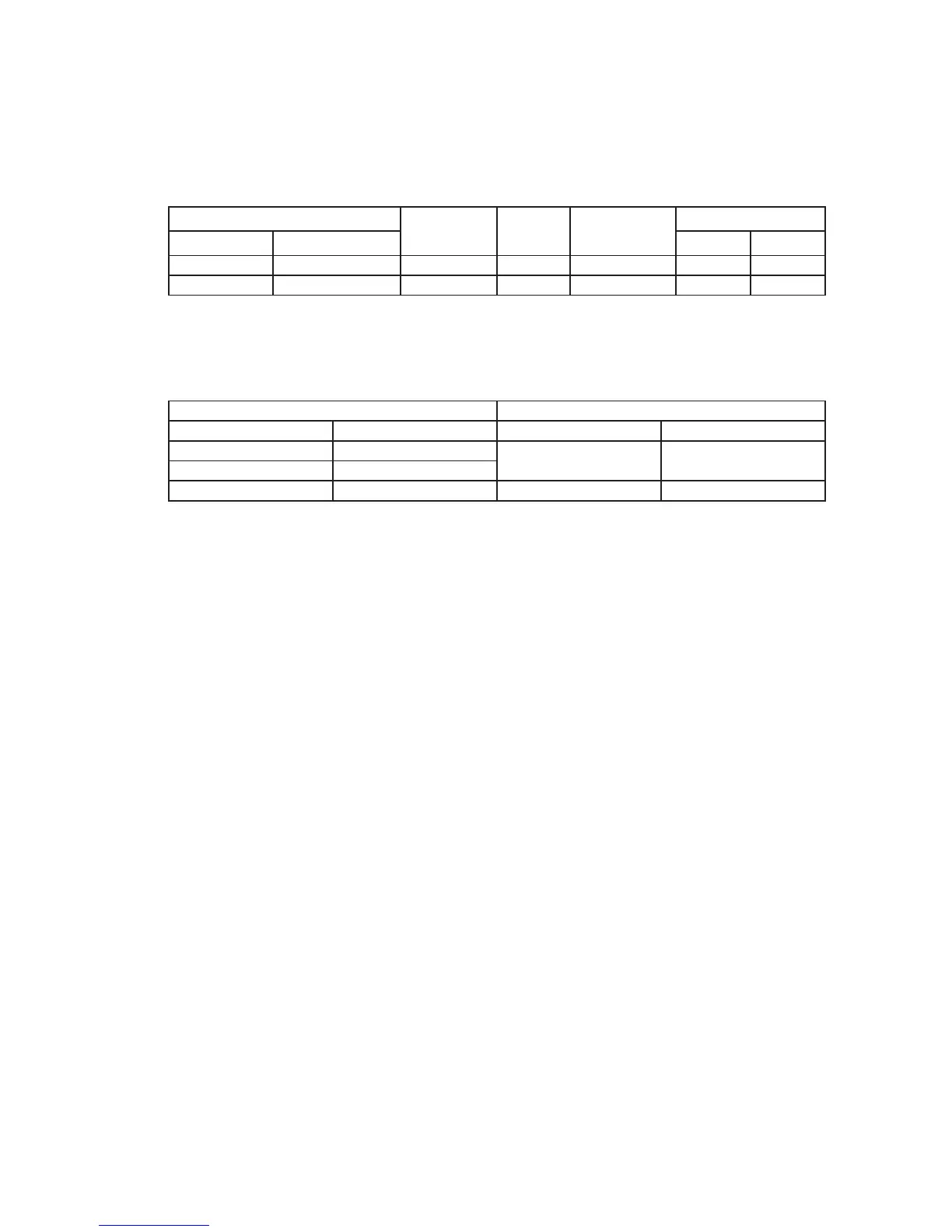

CHART 2 – FLUID NOZZLE RANGE & FLUID NEEDLE

FLUID NOZZLE FLUID NEEDLE

COMPUTER NO. PART NO. COMPUTER NO. PART NO.

803298* SRIPRO-200-08-K*

803302 SRIPRO-300-0810-K

803299* SRIPRO-200-10-K*

803300* SRIPRO-200-12-K* 803303 SRIPRO-300-1214-K

*Includes (1) SRIPRO-2 separator

NOTE: When replacing the fluid nozzle or fluid needle, replace both at the same time. Torque to 80-90 in-lbs (9-10 Nm).

Don’t over tighten the fluid nozzle. Use SRI-50 (6mm) wrench supplied with the gun and check with a torque wrench.

IMPORTANT NOTE: The SRI PRO and old SRI fluid nozzles and aircaps ARE NOT INTERCHANGEABLE between the

2 models. Any attempt to fit fluid nozzles or caps onto the wrong Spray Gun may cause damage to the parts or the

Spraygun body and invalidate the warranty.

Loading...

Loading...