10.

THE

VARIOUS

OPERATING

ADJUSTMENTS

OF

BASIC

MACHINE

The

numbers

in

bracki

10.1

Arm

Rotation

refer

to

those

in the

''Controls"

illustrations

on

page

2

The

radial

arm

rotates

to

right

or

left

for

mitre cuts.

Release

the

mitre clamp handle (18)

and the

mitre latch

(19).

Then swing

the arm (2)

right

or

left

to the

required

angle. Then lock

the

clamp

handle(18).

The

calibrated mitre scale

(1)

is

just below

the

elevating

handle

and

indicates

the

angle

of the arm

relative

to the

'0'

straight cross-cut position.

The

mitre latch

(15)

is

only used

to

locate

the arm in the

0° and 45°

positions

but

adopt

the

habit

of

using

the

mitre

clamp handle also

to

secure

the arm in

this,

as

well

as any

other,

position.

10.2

Blade

Height

The

Radial Arm,

and

hence also

the Saw

blade,

can be

raised

or

lowered

by

turning

the

elevating

handle

(6)

top

of the

column. Each complete rotation

of the

handle

moves

the

blade

up or

down

by

about 3mm.

10.3 Yoke

Assembly

Rotation

Changing from cross-cut

to the rip

position takes

only

seconds.

Release

the rip

slide

bar (4) and the

yoke clamp (10)

and

then

swing

the

yoke

to

right

or

left.

The

yoke locks

automatically

at the

four

90°

positions,

but

remember

to

always secure

the

yoke clamp also

to

maximise accuracy.

10.4

Blade

Tilting

Turn

the

elevating handle

to

raise

the

sawblade

well

above

the

table. Release bevel clamp (12)

and

bevel

latch

(1'

Tilt

the

motor

to the

desired

angle

on the

bevel

scale.

With

clamp released,

the

latch will automatically locate

in the

popular

0°. 45° and 90°

angle positions.

11.

MAKING

THE

BASIC

CUTS

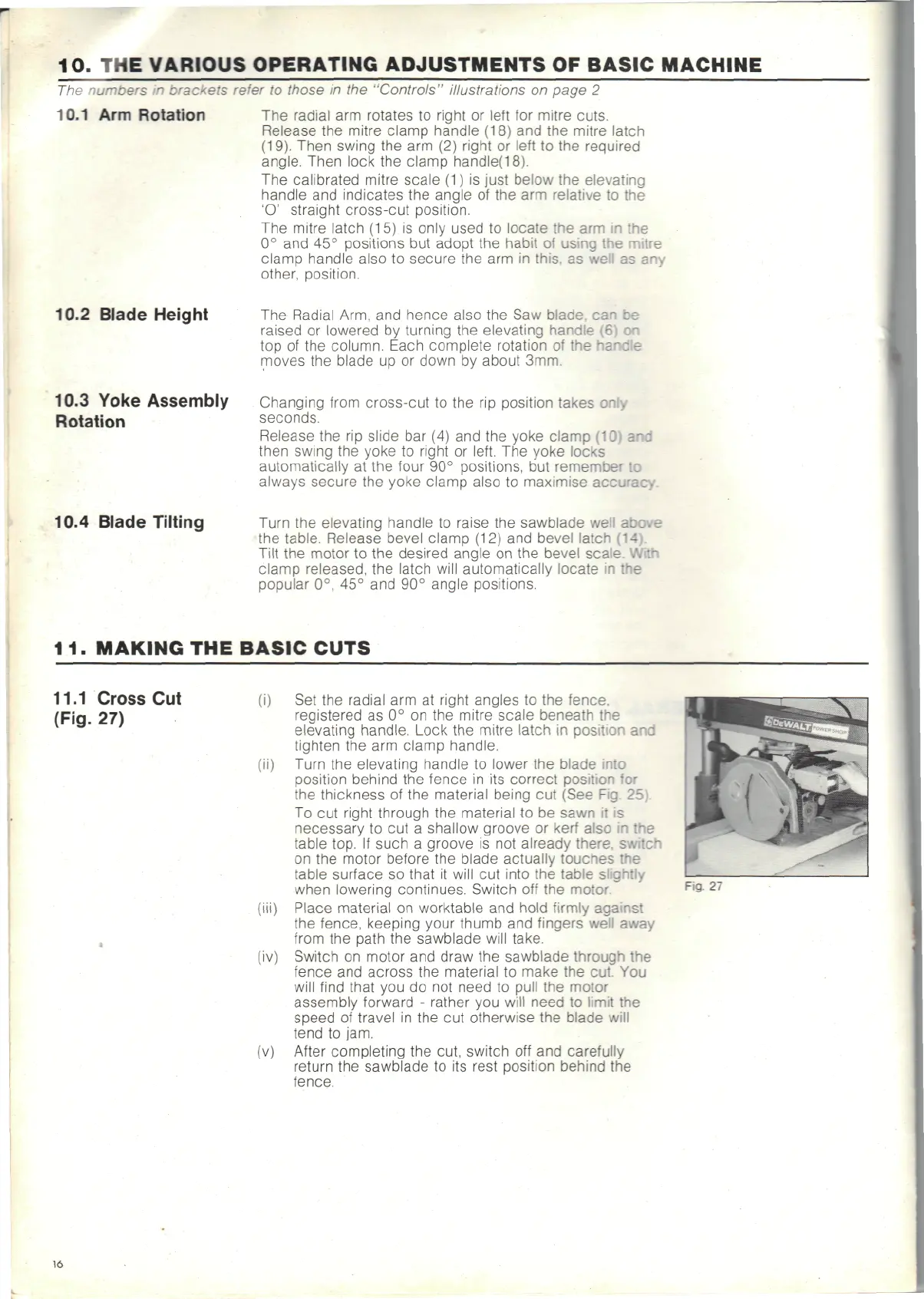

11.1

Cross

Cut

(Fig.

27)

(iii)

(v)

Set

the

radial

arm at

right angles

to the

fence.

registered

as 0° on the

mitre scale beneath

the

elevating

handle.

Lock

the

mitre

latch

in

position

and

tighten

the arm

clamp handle.

Turn

the

elevating handle

to

lower

the

blade

into

position

behind

the

fence

in its

correct

position

for

the

thickness

of the

material being

cut

(See Fig.

25)

To

cut

right through

the

material

to be

sawn

it is

necessary

to cut a

shallow groove

or

kerf

also

in the

table top.

If

such

a

groove

is not

already

there,

switch

on

the

motor before

the

blade actually

touches

the

table surface

so

that

it

will

cut

into

the

table

slightly

when lowering continues. Switch

off the

motor.

Place

material

on

worktable

and

hold

firmly

against

the

fence, keeping your thumb

and

fingers

well

away

from

the

path

the

sawblade will take.

Switch

on

motor

and

draw

the

sawblade

through

the

fence

and

across

the

material

to

make

the

cut.

You

will

find that

you do not

need

to

pull

the

motor

assembly forward

-

rather

you

will need

to

limit

the

speed

of

travel

in the cut

otherwise

the

blade

will

tend

to

jam.

After

completing

the

cut, switch

off and

carefully

return

the

sawblade

to its

rest position

behind

the

fence.

Fig.

27

16

Loading...

Loading...