Fig.

42

(v)

Now,

tilt

the

motor

to its 90°

position

on the

bevel

scale

so

that

the

Shaping

Head

is

horizontal.

(vi)

Before operating

the

machine

you

should

now

mount

the

special Shaping Head

guard

and

adjust

its

position depending

on the

depth

of

knife

profile

you

intend

to use

(Fig. 39).

Position

the

yoke assembly

on the arm so

that only

the

amount

of

knife profile required

extends

in

front

of

the

fence.

The

height

of the

Shaping

Head

above

the

table will depend

on the

height

of

your

material

and

the

position

the

moulding

is to

trace

on it. If the

Shaping Head needs

to be in a

position

otherwise

obstructed

by the

fence,

you

have

the

following

two

options:

EITHER

A. Cut

away

a

section

of the

existing

fence

to

provide sufficient space

for the

block

and

guard

to

protrude through it*.

OR

B.

Position

two

pieces

of

timber

(of the

same

thickness

as the

fence provided)

in the

fence position,

one on

either side

of the

moulding

block.

"Note:-

If you

choose option

A, it is

recommended that

you

replace

the

modified fence with

a

complete

new

fence

for

normal sawing operations.

(viii)

Having locked

the

yoke assembly into position

on the

arm

with

the rip

lock

and

positioned

the

guard

so

that

it

just clears

the

material, feed

the

material firmly

and

evenly

along

the

fence from

the

right into

the

shaper

cutters. Maintain positive pressure.

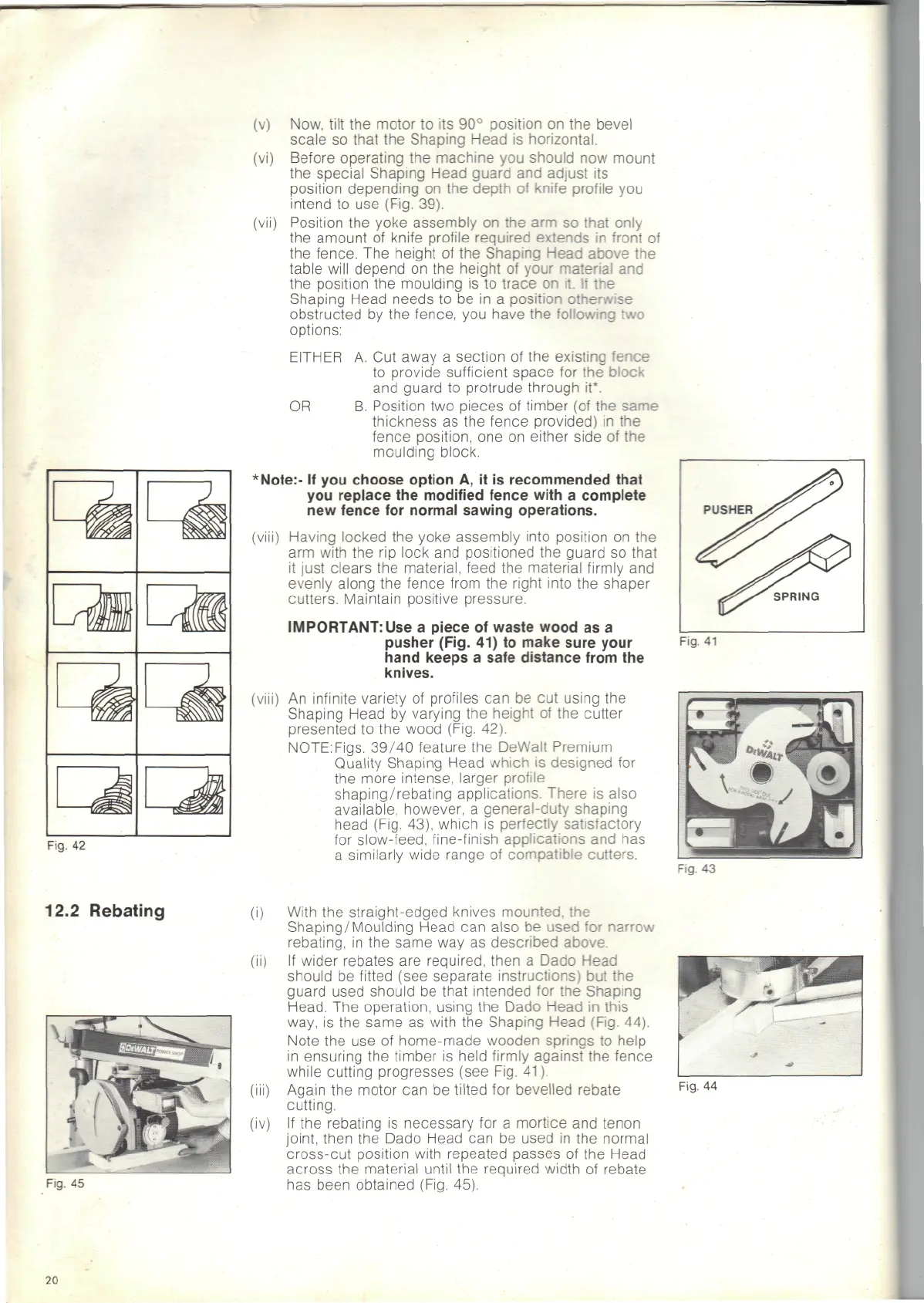

IMPORTANT:Use

a

piece

of

waste wood

as a

pusher (Fig.

41) to

make sure your

hand keeps

a

safe distance from

the

knives.

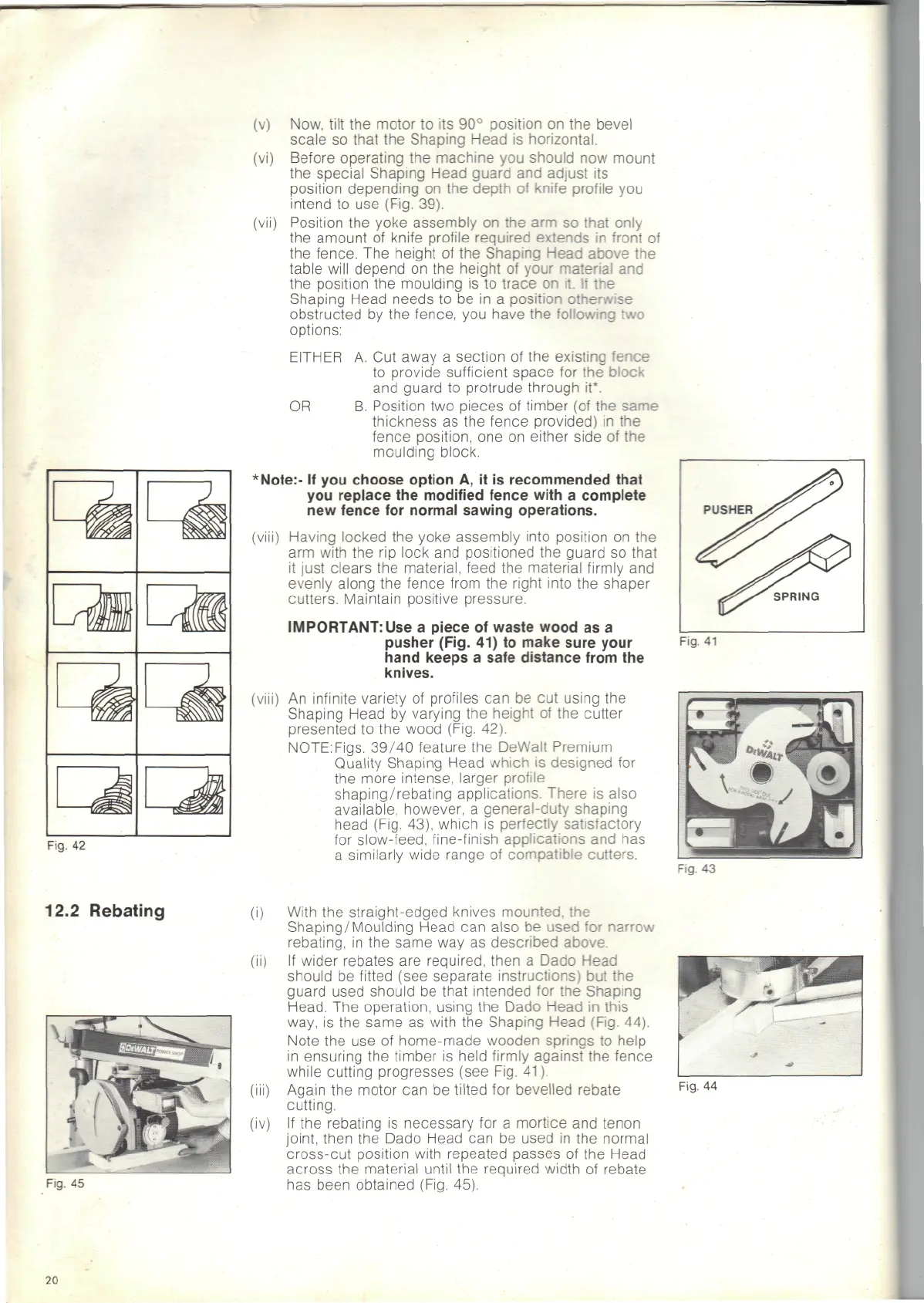

(viii)

An

infinite variety

of

profiles

can be cut

using

the

Shaping Head

by

varying

the

height

of the

cutter

presented

to the

wood (Fig. 42).

NOTE:Figs.

39/40

feature

the

DeWalt

Premium

Quality Shaping

Head

which

is

designed

for

the

more intense, larger

profile

shaping/rebating applications.

There

is

also

available,

however,

a

general-duty

shaping

head (Fig. 43), which

is

perfectly satisfactory

for

slow-feed,

fine-finish

applications

and has

a

similarly wide range

of

compatible

cutters.

PUSHER

SPRING

Fig.

41

Fig.

43

12.2 Rebating

Fig.

45

(i)

With

the

straight-edged knives

mounted,

the

Shaping/Moulding

Head

can

also

be

used

for

narrow

rebating,

in the

same

way as

described

above.

(ii)

If

wider rebates

are

required, then

a

Dado Head

should

be

fitted (see separate instructions)

but the

guard used should

be

that intended

for the

Shaping

Head.

The

operation,

using

the

Dado

Head

in

this

way,

is the

same

as

with

the

Shaping Head (Fig. 44).

Note

the use of

home-made wooden springs

to

help

in

ensuring

the

timber

is

held firmly against

the

fence

while cutting progresses (see Fig.

41).

(iii)

Again

the

motor

can be

tilted

for

bevelled

rebate

cutting.

(iv)

If the

rebating

is

necessary

for a

mortice

and

tenon

joint,

then

the

Dado Head

can be

used

in the

normal

cross-cut position with repeated passes

of the

Head

across

the

material until

the

required

width

of

rebate

has

been obtained (Fig. 45).

Fig.

44

20

Loading...

Loading...