12.8 Drilling/Boring

Fig.

69

12.9 Special Mitre

Fences

Fig.

70

12.10 Automatic

Safety

Return

12.11 Legstands

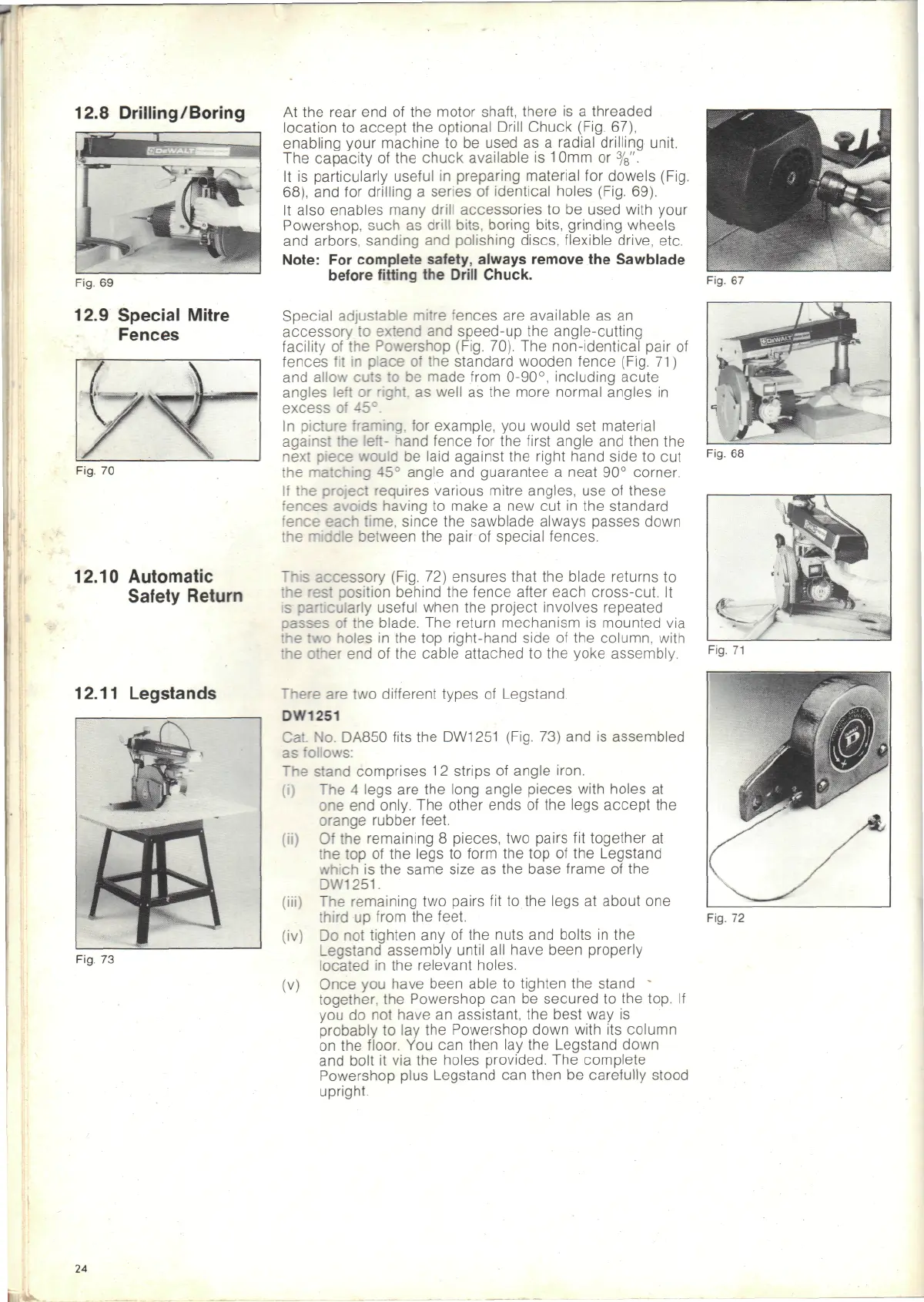

Fig.

73

At

the

rear

end of the

motor

shaft,

there

is a

threaded

location

to

accept

the

optional Drill Chuck (Fig. 67),

enabling your machine

to be

used

as a

radial

drilling

unit.

The

capacity

of the

chuck

available

is

10mm

or

%".

It

is

particularly useful

in

preparing material

for

dowels (Fig.

68),

and for

drilling

a

series

of

identical holes (Fig. 69).

It

also enables many

drill

accessories

to be

used with your

Powershop,

such

as

drill

bits,

boring

bits,

grinding

wheels

and

arbors, sanding

and

polishing discs, flexible drive, etc.

Note:

For

complete

safety,

always remove

the

Sawblade

before

fitting

the

Drill Chuck.

Special adjustable mitre fences

are

available

as an

accessory

to

extend

and

speed-up

the

angle-cutting

facility

of the

Powershop (Fig. 70).

The

non-identical pair

of

fences

fit in

place

of the

standard wooden fence (Fig.

71)

and

allow

cuts

to be

made from 0-90°, including acute

angles left

or

right,

as

well

as the

more normal angles

in

excess

of

45°.

In

picture

framing,

for

example,

you

would

set

material

against

the

left-

hand

fence

for the

first

angle

and

then

the

next

piece

would

be

laid against

the

right

hand side

to cut

the

matching

45°

angle

and

guarantee

a

neat

90°

corner.

If the

project

requires various mitre angles,

use of

these

fences

avoids

having

to

make

a new cut in the

standard

fence

each

time,

since

the

sawblade always passes down

the

middle

between

the

pair

of

special fences.

This

accessory

(Fig.

72)

ensures that

the

blade returns

to

the

rest

position behind

the

fence after each cross-cut.

It

is

particularly

useful when

the

project involves repeated

passes

of the

blade.

The

return mechanism

is

mounted

via

the two

holes

in the top

right-hand side

of the

column, with

the

other

end of the

cable attached

to the

yoke assembly.

There

are two

different types

of

Legstand.

DW1251

Cat.

No.

DA850

fits

the

DW1251

(Fig.

73) and is

assembled

as

follows:

The

stand

comprises

12

strips

of

angle iron.

(i) The 4

legs

are the

long angle pieces with holes

at

one end

only.

The

other ends

of the

legs

accept

the

orange rubber feet.

(ii)

Of the

remaining

8

pieces,

two

pairs

fit

together

at

the top of the

legs

to

form

the top of the

Legstand

which

is the

same size

as the

base frame

of the

DW1251.

(iii)

The

remaining

two

pairs

fit to the

legs

at

about

one

third

up

from

the

feet.

(iv)

Do not

tighten

any of the

nuts

and

bolts

in the

Legstand assembly

until

all

have been properly

located

in the

relevant holes.

(v)

Once

you

have been able

to

tighten

the

stand

'

together,

the

Powershop

can be

secured

to the

top.

If

you

do not

have

an

assistant,

the

best

way is

probably

to lay the

Powershop down with

its

column

on

the

floor.

You can

then

lay the

Legstand down

and

bolt

it via the

holes provided.

The

complete

Powershop plus Legstand

can

then

be

carefully stood

upright.

Fig.

67

Fig.

68

Fig.

71

Fig.

72

24

Loading...

Loading...