11.9

Circle

Cutting

(Fig.

38)

Although

a

circular

saw is

normally thought

of as

only able

to

make straight

cuts,

cutting

perfect circles

is

also quite

straightforward

on

your radial

arm saw

using only

the

standard

circular

saw

blade.

Cramp

a

false table

to the

main one,

or

substitute

a

strip

as

thick

as the

table

itself

in

place

of the

fence.

Use a

woodscrew

as a pin and

screw this part

way

into

the

chosen

aid,

and

then

saw the

head off. Make

a

hole

in the

underside

of the

wood, from

which

the

circle

is to be

formed,

and

then

fit to the

pin.

Lower

the

blade just clear

of

the

wood,

and

lock

the

carriage

at a

tangent

to the

proposed

circular

cut.

Hold

the

wood firmly

and

lower

the

arm by

half

a

turn. Then using both hands rotate

the

wood

on the pin in a

clockwise direction against

the

blade.

After

each

revolution

lower

the arm by

half

a

turn

until

all the

waste

is cut

away,

and the

circular piece

is

formed.

Fig.

38

12.

OPERATION

OF THE

MACHINE WITH OPTIONAL ATTACHMENTS

AND

ACCESSORIES

Even

in its

standard form with

the

basic general purpose

sawblade,

the

Powershop

is

already more versatile than

any

other type

of

sawing system.

The

range

of

optional attachments, however,

add a

further

dimension

to

your woodworking potential. They

will

turn

your

Powershop into

a

complete workshop.

You

will

find

the

optional

TCT saw

blades prove

advantageous, particularly when cutting hardwoods

and

man-made

materials.

TCT

blades require less frequent

'sharpening

and

have

a

much longer

life

than ordinary steel

blades.

Note:

Never

use

blades larger than 250mm diameter

—

an

imperial

10"

blade

measures 254mm diameter

and is

therefore

too

large.

Before

mounting

or

changing

any

attachments

or

accessories,

disconnect your Powershop from

the

mains

power supply.

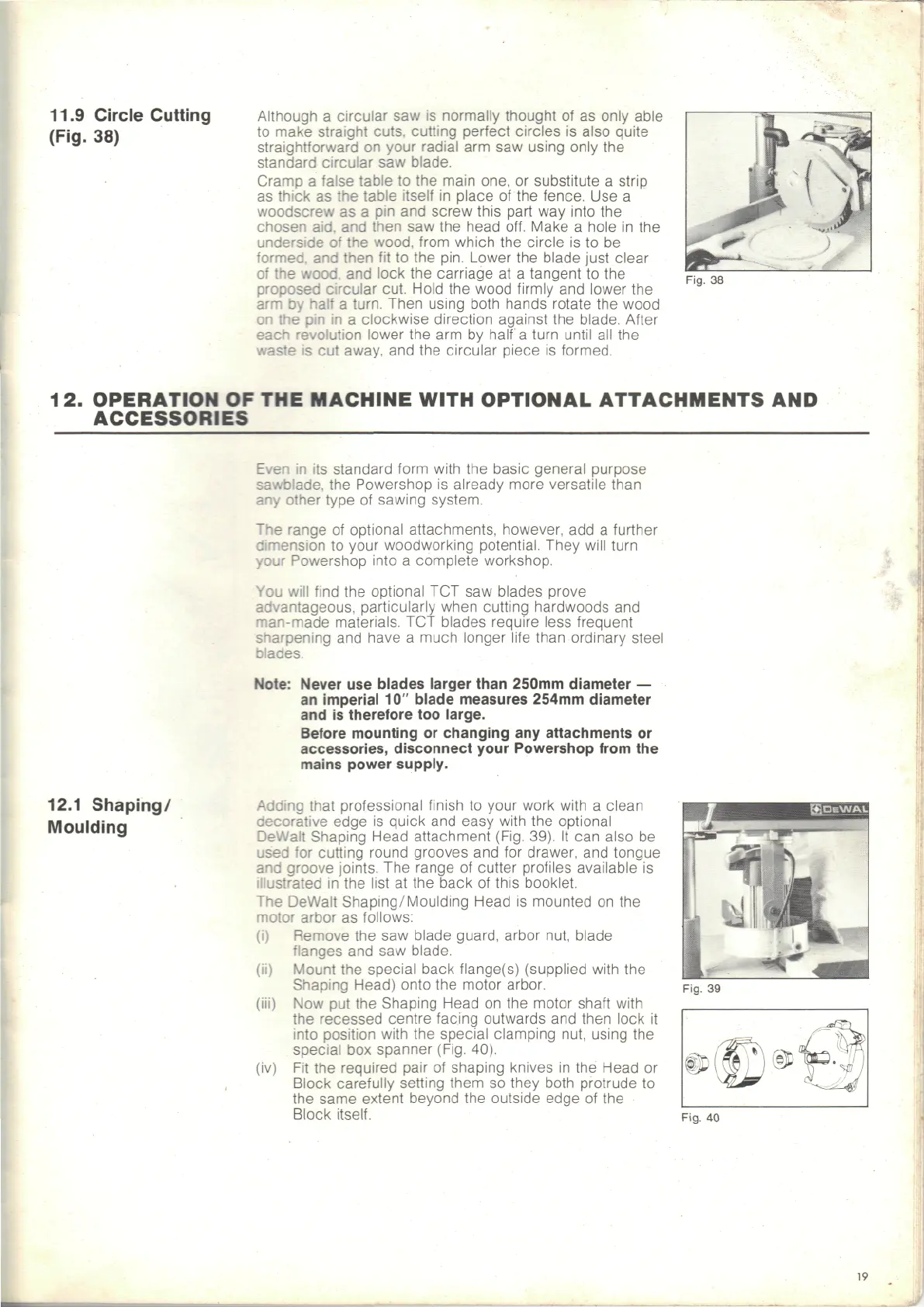

12.1

Shaping/

Moulding

Adding

that

professional

finish

to

your work with

a

clean

decorative

edge

is

quick

and

easy with

the

optional

DeWalt Shaping Head

attachment

(Fig.

39).

It can

also

be

used

for

cutting

round grooves

and for

drawer,

and

tongue

and

groove joints.

The

range

of

cutter profiles available

is

illustrated

in the

list

at the

back

of

this booklet.

The

DeWalt Shaping/Moulding Head

is

mounted

on the

motor arbor

as

follows:

(i)

Remove

the saw

blade guard, arbor

nut,

blade

flanges

and saw

blade.

(ii) Mount

the

special back flange(s) (supplied with

the

Shaping Head) onto

the

motor arbor.

(iii)

Now put the

Shaping Head

on the

motor

shaft

with

the

recessed centre facing outwards

and

then lock

it

into position with

the

special clamping

nut,

using

the

special

box

spanner (Fig. 40).

(iv)

Fit the

required pair

of

shaping knives

in the

Head

or

Block

carefully setting them

so

they both protrude

to

the

same extent beyond

the

outside edge

of the

Block

itself.

Fig.

39

Fig.

40

19

Loading...

Loading...