PPC2 AF OPERATION AND MAINTENANCE MANUAL

© 1998 DH Instruments, Inc. Page 122

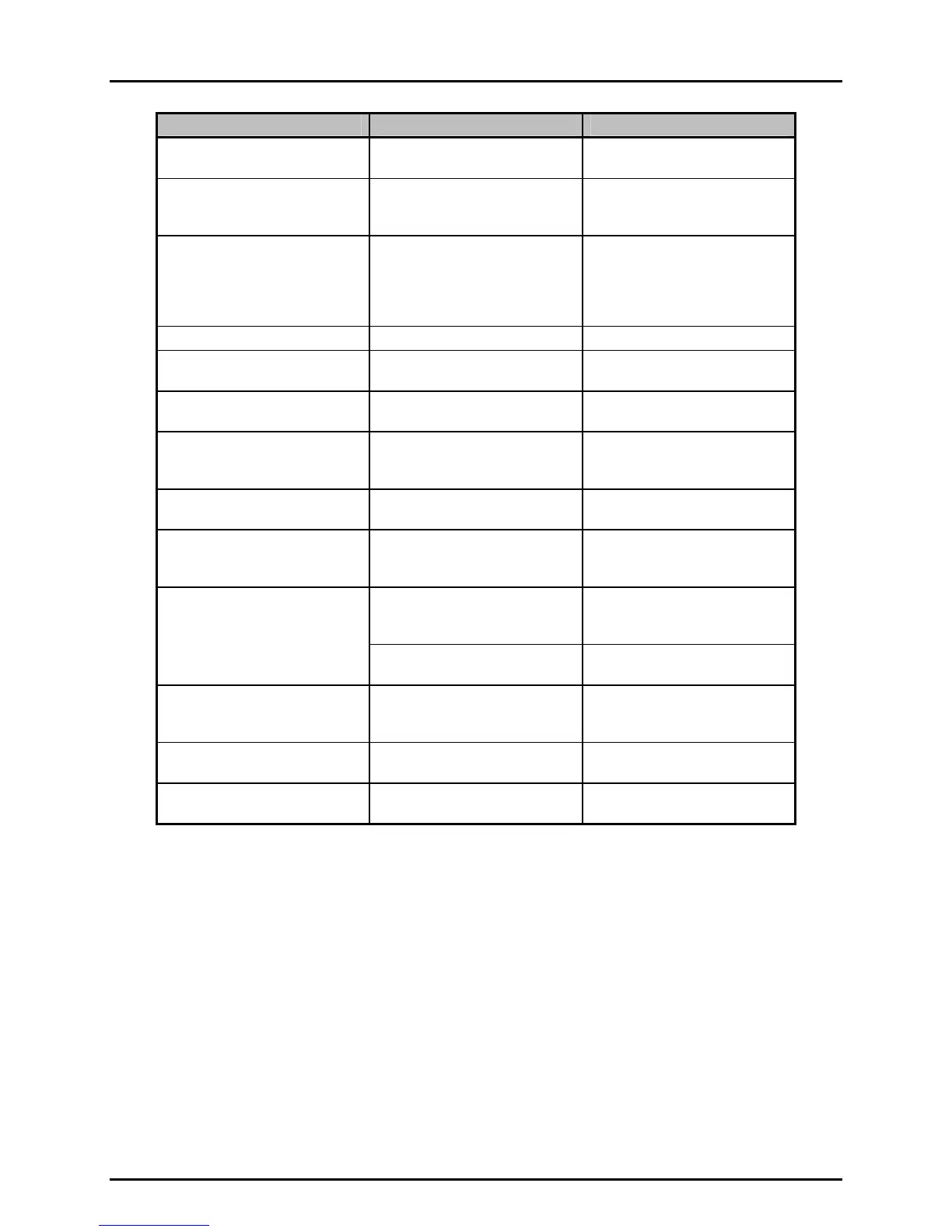

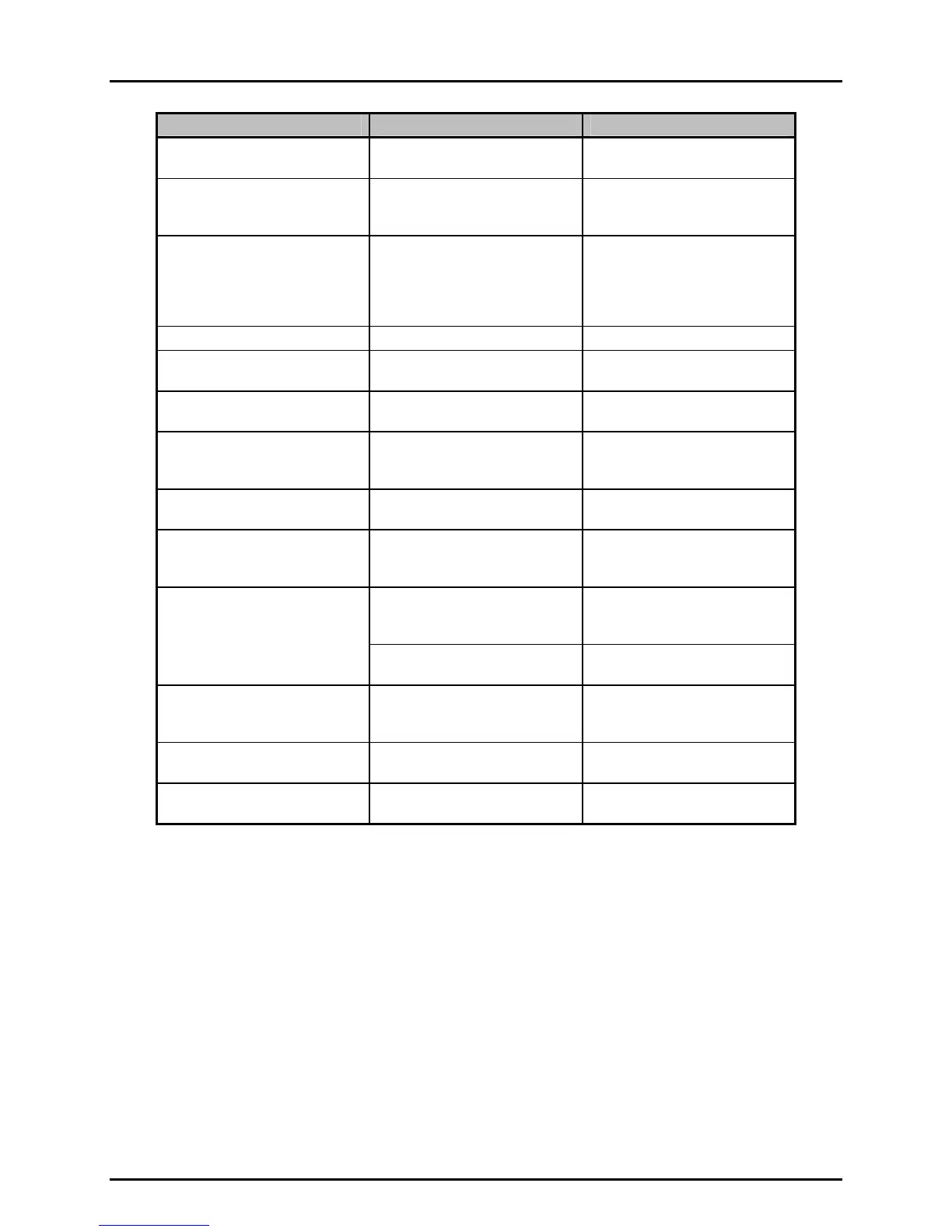

SYMPTOM POSSIBLE CAUSE SOLUTION

Will not set pressure.

Pressure and/or vacuum supply

incorrectly connected or not adequate.

Correct pressure and/or vacuum

supply (2.3.3, 2.3.4).

Disagreement between Hi and Lo

reference transducer or between

transducer ranges appears excessive.

Difference is actually in tolerance and

represents “natural” disagreement..

Compare differences observed to

tolerances on reference transducer

measurements (1.3.2)

Disagreement between

measurements made by different

ranges at the same pressure is not

zero but an autozero routine was just

executed.

Readings by different ranges at the

same pressure can disagree even

after a valid autozero.

Check that disagreement between

ranges is within tolerance (1.3.2, 5.2).

Will not set pressure. Target exceeds UL range. Check UL (3.2.4) and range (3.2.1).

Will not set pressure.

There is a very large leak in the test

system or TEST port is not connected.

Correct leak.

Poor pressure control at low

pressures.

ControlRef not properly set to reflect

pressure conditions at EXHAUST port.

Set ControlRef properly (3.3.1).

Poor pressure control at pressures

under atmosphere or inability to reach

pressures under atmosphere.

Vacuum supply is incorrectly

connected, is not low enough or is

unstable.

Correct vacuum supply (2.3.4, 3.3.1).

Poor pressure control characterized

by "hunting" around target.

Pneumatic control module needs to be

reconfigured.

Reconfigure control module (5.1.1)

Poor pressure control characterized

by control stopping completely near

the target pressure.

Control mode is set to static rather

than dynamic.

Set control mode to dynamic (3.1.2.3,

3.2.3)

There is a restriction in the test

connection between the PPC2 AF and

the test.

Remove the restriction to allow free

flow between the PPC2 AF and the

test.

Poor pressure control characterized

by excessive overshooting and/or

undershooting, inability to "lock-on"

target.

A filter in the PPC2 AF, the SPLT or an

accessory is dirty and causing a restriction.

Clean and dry or replace the filter

element (5.1.3).

Poor pressure control characterized

by excessive pressure noise at control

point and/or hunting around target.

Excessive leak present in system.

Correct internal or external leak (3.2.8,

5.1.2).

Poor pressure control characterized

by minor overshooting.

Some overshooting is part of normal

operation to speed up operation.

Check whether overshooting is within

normal limits (3.1.2.3).

Poor pressure control characterized

by very slow slew rate.

Test volume is beyond normal limits.

Reduce test volume if slew rate is

unacceptable (1.3.3)

Loading...

Loading...