CROSS5E CROSS5EH CROSS7E CROSS7EH CROSS8E

Power supply 230 V~ / 50 Hz 230 V~ / 50-60 Hz 230 V~ / 50 Hz 230 V~ / 50-60 Hz 230 V~ / 50 Hz

Absorption 1,5 A 1,2 A 2 A 1,5 A 3 A

Thrust 500 N 400 N 700 N 600 N 800 N

Condenser 12,5 µF - 16 µF - 22 µF

Max run 20 m 20 m 20 m 20 m 20 m

Door speed 0,18 m/s 0,09 - 0,21 m/s 0,18 m/s 0,12 ÷ 0,20 m/s 0,18 m/s

Max door weight 400 kg 450 kg 600 kg 600 kg 800 kg

Service class 3 - FREQUENT 4 - INTENSIVE 4 - INTENSIVE 4 - INTENSIVE 4 - INTENSIVE

Min number of

consecutive cycles

20 50 30 50 30

Intermittence

S2 = 15 min

S3 = 25%

S2 = 30 min

S3 = 50%

S2 = 20 min

S3 = 50%

S2 = 30 min

S3 = 50%

S2 = 20 min

S3 = 50%

Temperature -20 °C/+55 °C -20 °C/+55 °C -20 °C/+55 °C -20 °C/+55 °C -20 °C/+55 °C

Degree of protection IP24D IP24D IP24D IP24D IP24D

Control panel E1 73RM E1A 73RG E1A

2. REFERENCE TO ILLUSTRATIONS

The given operating and performance features can only be

guaranteed with the use of DITEC accessories and safety

devices.

2.1 Standard installation references (fig. 1)

[1] Radio

[2] Flashing light

[3] Key selector

[4] Geared motor + control panel

[5] Photocells

[6] Rubber edge - sensitive edge

[7] Opening and closing stop

[8] Connect power supply to an type-approved omnipole

switch with a contact opening gap of no less that 3 mm

(not supplied by us)

Connection to the grid is made with independent channels

and separated from the connections to the control and

safety devices.

2.2 Geared motor references (fig. 3)

[9] Motor

[10] Casing

[11]

Manual release

[12] Control panel

[13] Limit-switch spring

[14] Pinion

[15] Internal photocell

[16] Courtesy light (optional)

[17]

BATK7 battery kit (optional, only CROSS5EH-7EH)

3. INSTALLATION

Unless otherwise specified, all measurements are expressed

in millimetres (mm).

3.1 Preliminary checks

Check the stability of the wing (derailing and lateral falls) and

the sliding wheels and that the upper guides do not cause any

friction.

The sliding guide must be securely fixed to the ground for the

full length within the doorway and must have no irregularities

that could hinder the movement of the gate.

The opening and closing stops must be fitted.

Note: make sure that the gate can not exit the sliding guides

and fall.

If the gate has slits, make sure they are covered to prevent

shearing points.

Safety device should be installed at the end of the wing to reduce

the collision force.

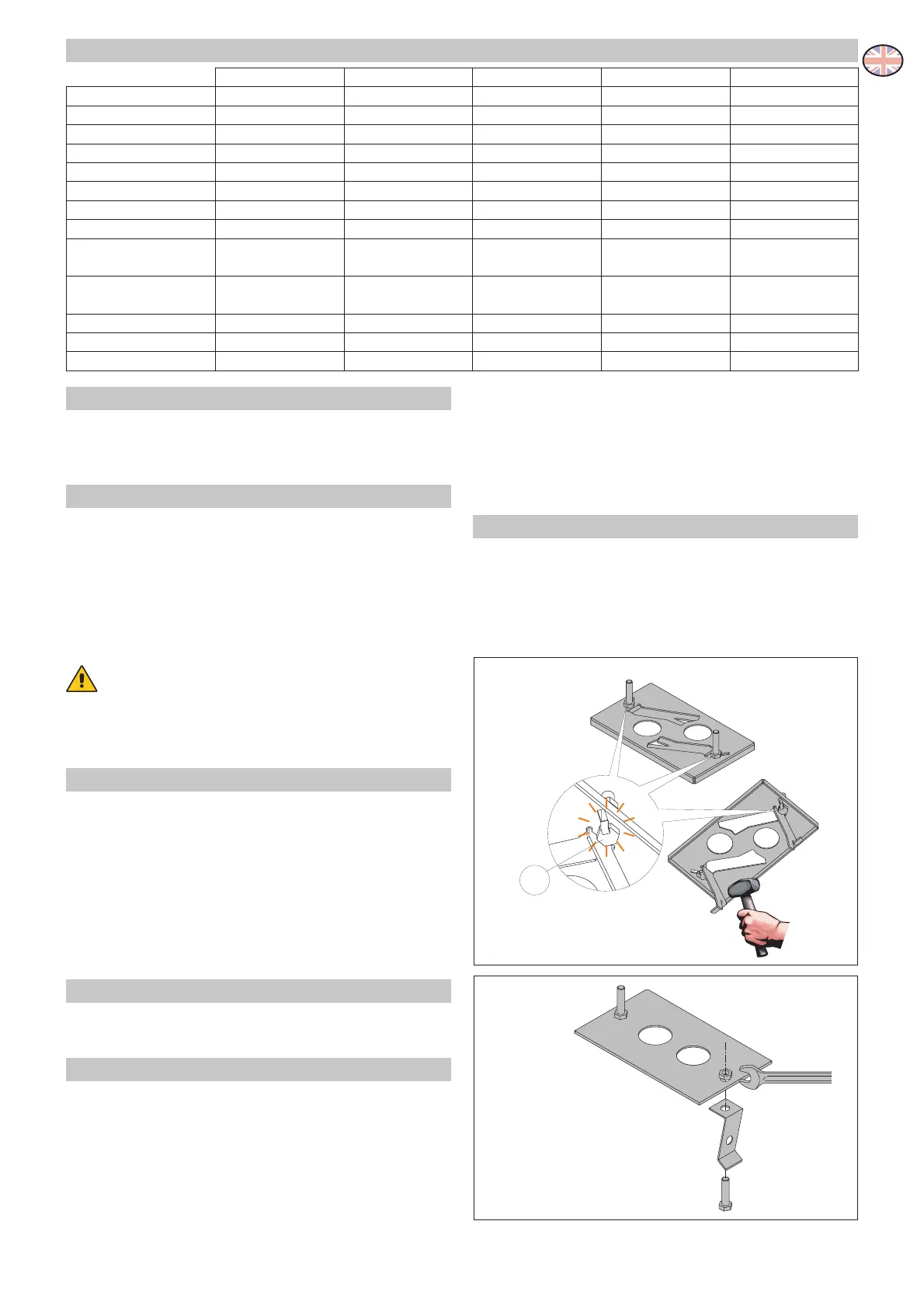

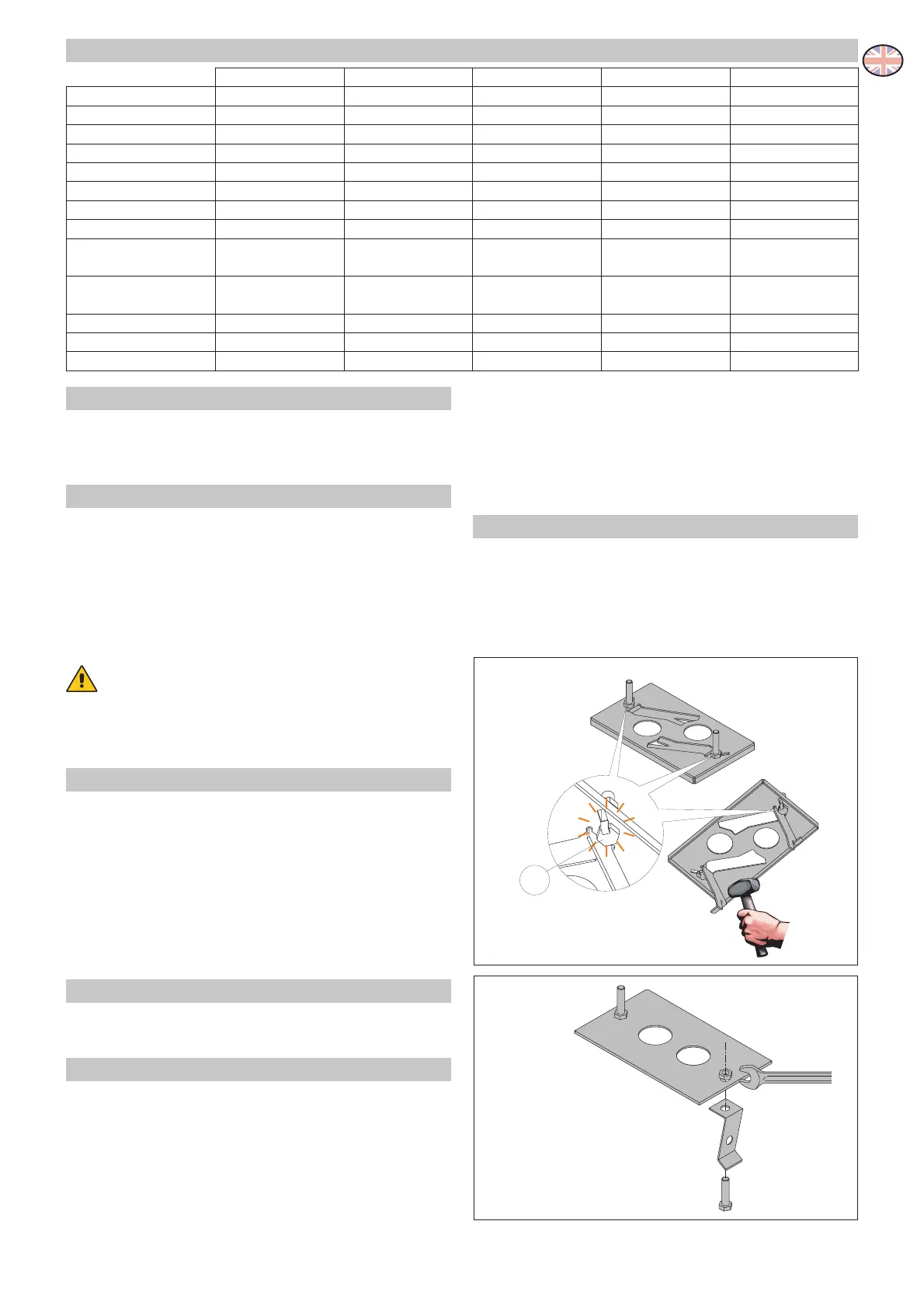

3.2 Base plate position

- First, insert the screws into the base plate blocking them

with a low nut [P], then, fold the tang to avoid displace-

ment.

- Take out the preformed wall anchors with a downward

movement and with the help of a hammer to ensure proper

anchorage to the concrete.

Loading...

Loading...