21

3. ASSEMBLY

ENGLISH

Fig. 5

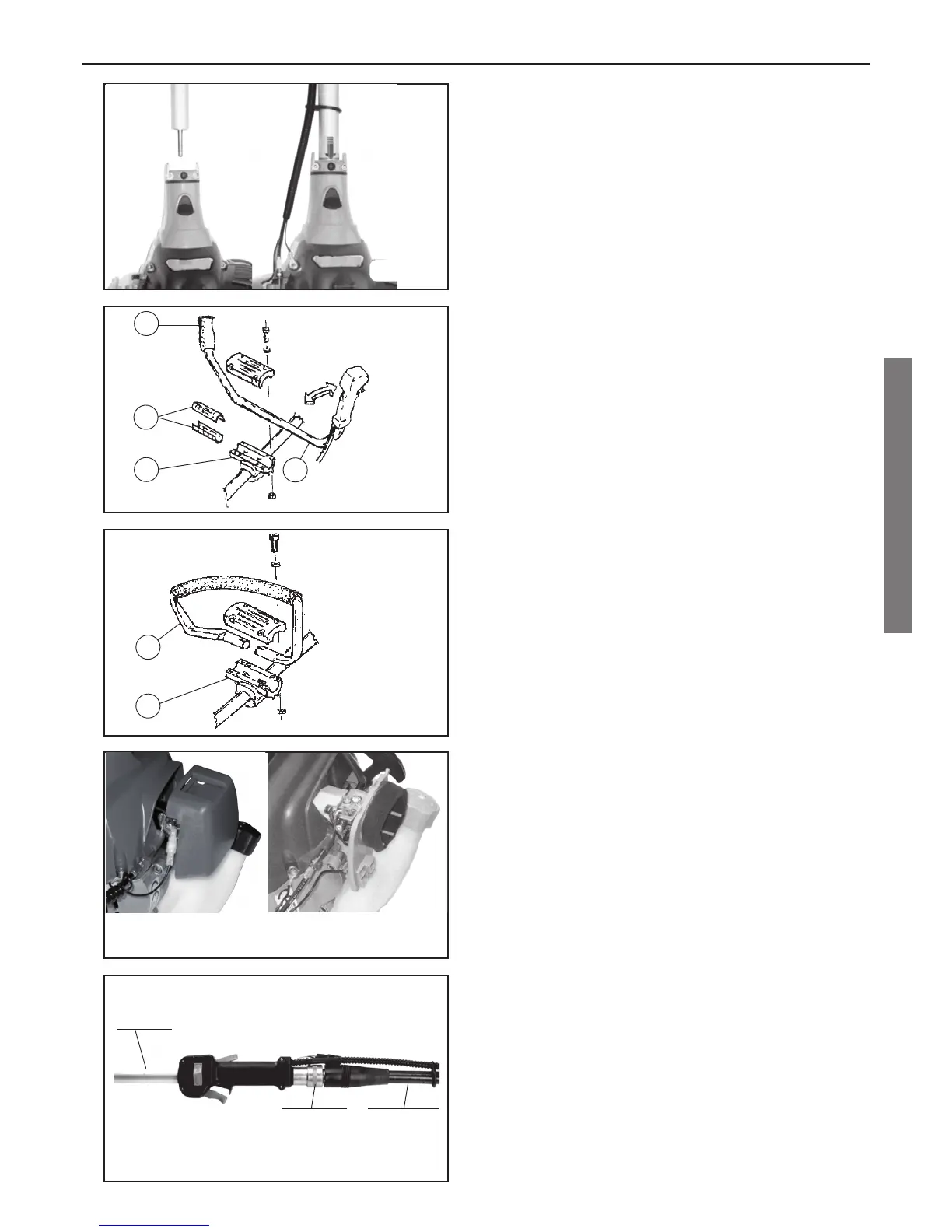

Fig. 6

Fig. 7

Fig. 4

A

C

B

D

E

F

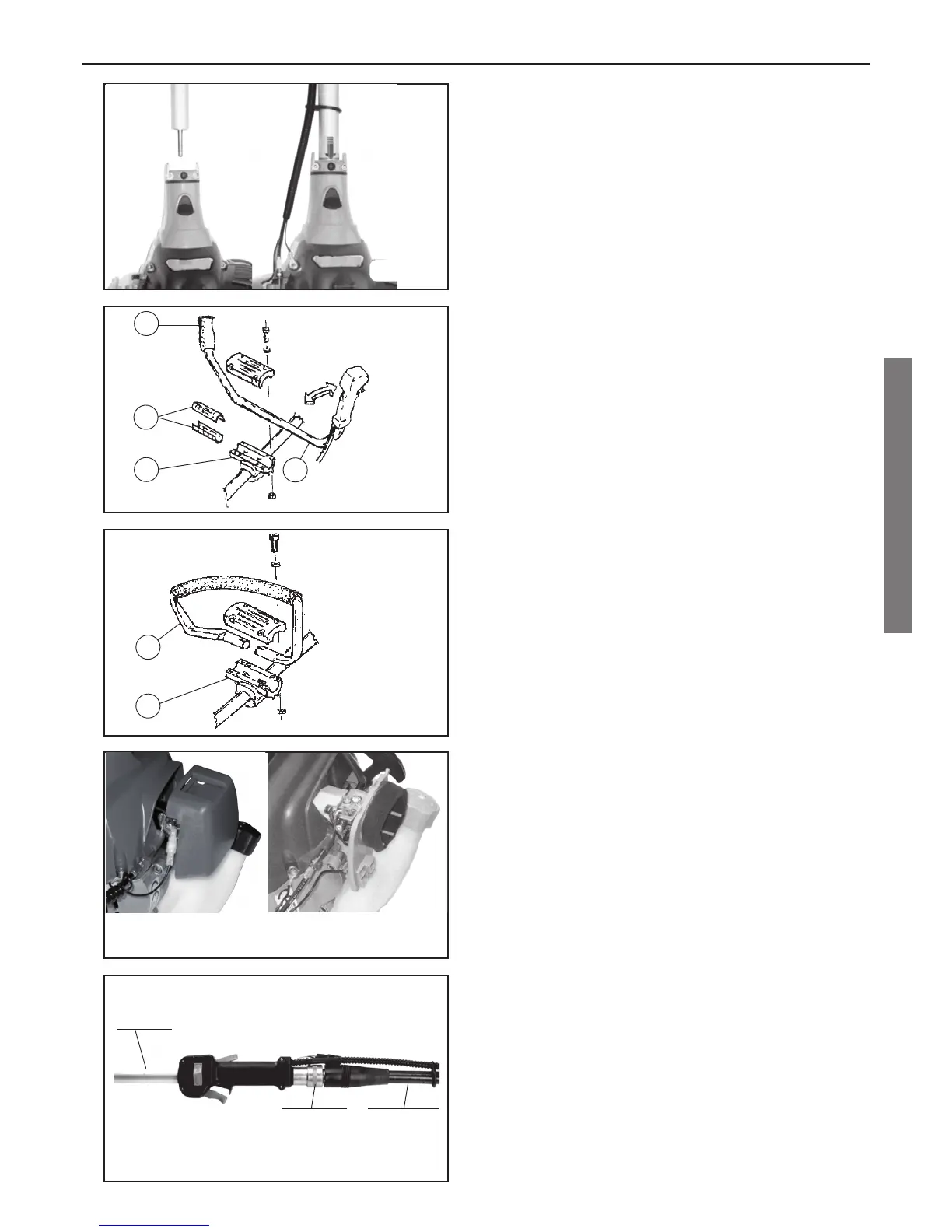

Fig. 8

Asta rigida

Long shaft

Attacco rapido

Quick coupling

Albero fl es si bi le

Flexible shaft

3. ASSEMBLY

3.1 Assembly

Make sure that all parts have been assembled cor rect ly

before start ing to work.

3.1.1 Models with rigid shaft

Rod-engine: (Fig. 4). After orienting the rod, connect it

to the en gine by inserting it in the hole in the clutch case.

In order to make sure that the rod has been in sert ed

correctly, check that the red line on the label lines up

with the profi le of the rod retainer jaws.

At this point, lock the rod in place in such way that it

cannot be removed from the engine and screw down

the two screws in the jaws.

Handle-bar: (Fig. 5). Proceed as follows to lock the

handle-bar securely to the rod: insert the two drilled

plate half-bearings A be tween the handle-bar support C

and the handle-bar pipe B, then take the handle-bar B

and position it so that it can be gripped with the con trol

handle with the accelerator cable in your right hand and

the simple grip D in your left hand. After positioning the

handle-bar B on the cross C, lock it in place with the

cross cover and the four respective fi xing screws.

Before fi xing the handle-bar in place, make sure it is

fastened so that your arms and wrists are fl exed slight ly

in normal work position. If you work in such way that

only your wrists are fl exed and your arms are straight,

the force required may be ex ces sive, es pe cial ly on your

right hand, which is un der constant strain by the need

to continuously work the accelerator trig ger.

Vibration-damping grip: (Fig. 6). Position the vi bra tion-

damping grip E in the cross F by keeping the long er

part facing left (this serves as a protective barrier dur ing

operation that prevents in vol un tary contact of your body

with the cutting accessory). Before de fi n i tive ly tight en ing

the fi xing screws, adjust it in a position that per mits the

ergonomic use of the machine.

Then defi nitively screw down the fi xing screws.

Connection of the gas control acceleration cable for

models with rigid shaft: (Fig. 7). There is a gas control

cable that leaves the accelerator handle. This cable has

a threaded terminal at its end, and there are two nuts

screwed into the terminal. Take the gas con trol cable

and insert one end into the swivel for the con trol of the

carburetor butterfl y valve. Then position the thread ed

ter mi nal into the respective housing in the nylon cylinder

cover, mak ing sure to pass the steel ca ble be neath the

respective track. Then fasten the thread ed ter mi nal to

the cylinder cover by work ing on the nuts. Then adjust

the threaded terminal in order to elim i nate all slack be-

tween the cable and the sheath in order to en sure cor rect

and progressive acceleration. This threaded ter mi nal

has been built to CE standards and serves to prevent

un de sired acceleration of the machine if the control is

ever ac ci den tal ly contacted. Then connect the ground

cable’s eyelet terminal to one of the four fi xing screws

on the cyl in der cover that sup ports the clutch case and

connect the ground cable’s female faston to the male

faston com ing from the coil. In models equipped with

handle-bars, pass the gas control cable unit inside the

re spec tive lat er al housings in the cross, and the two

cable guides po si tioned on the rod in order to make

sure that the gas con trol unit is fi tted as closely to the

machine as possible.

Loading...

Loading...