4. STARTING

24

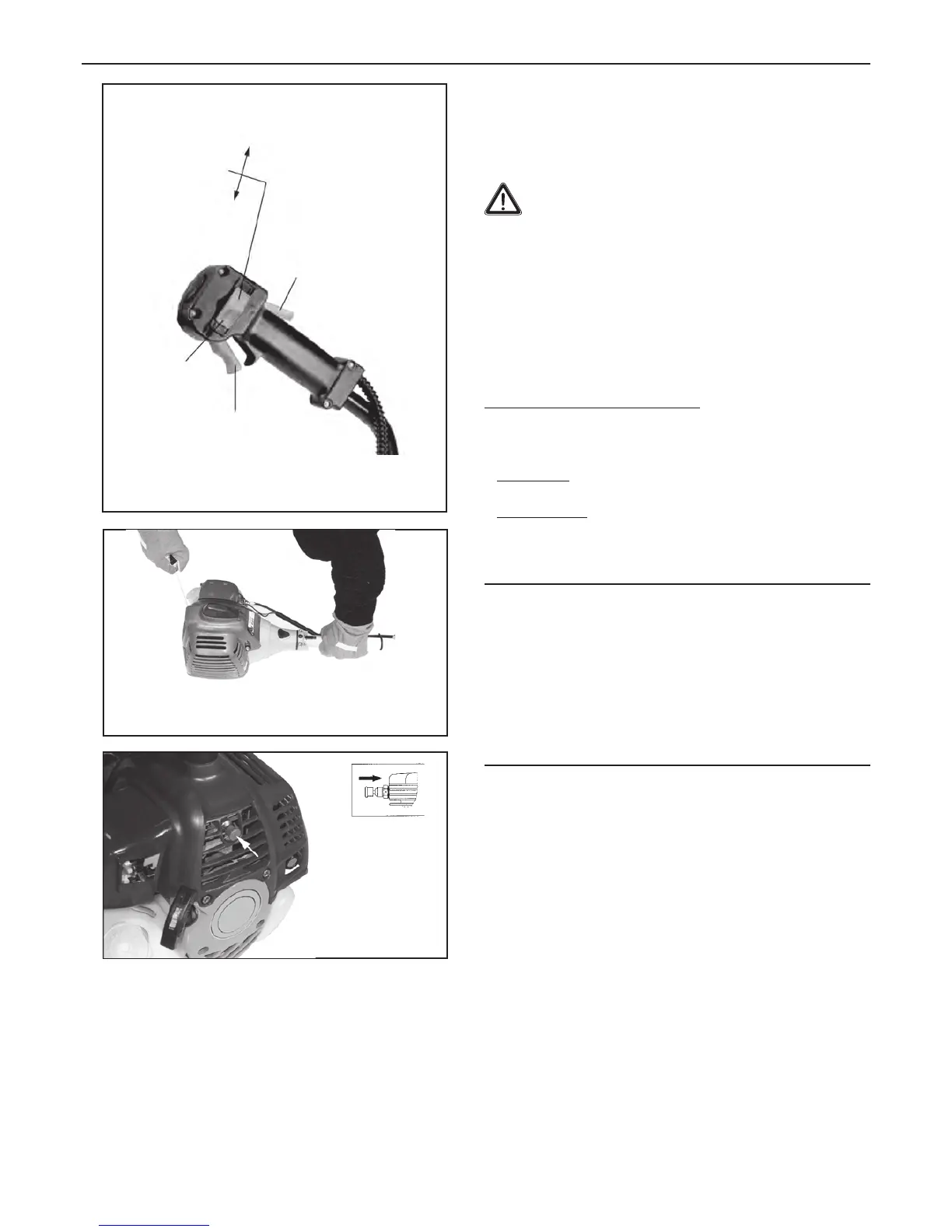

Fig. 20

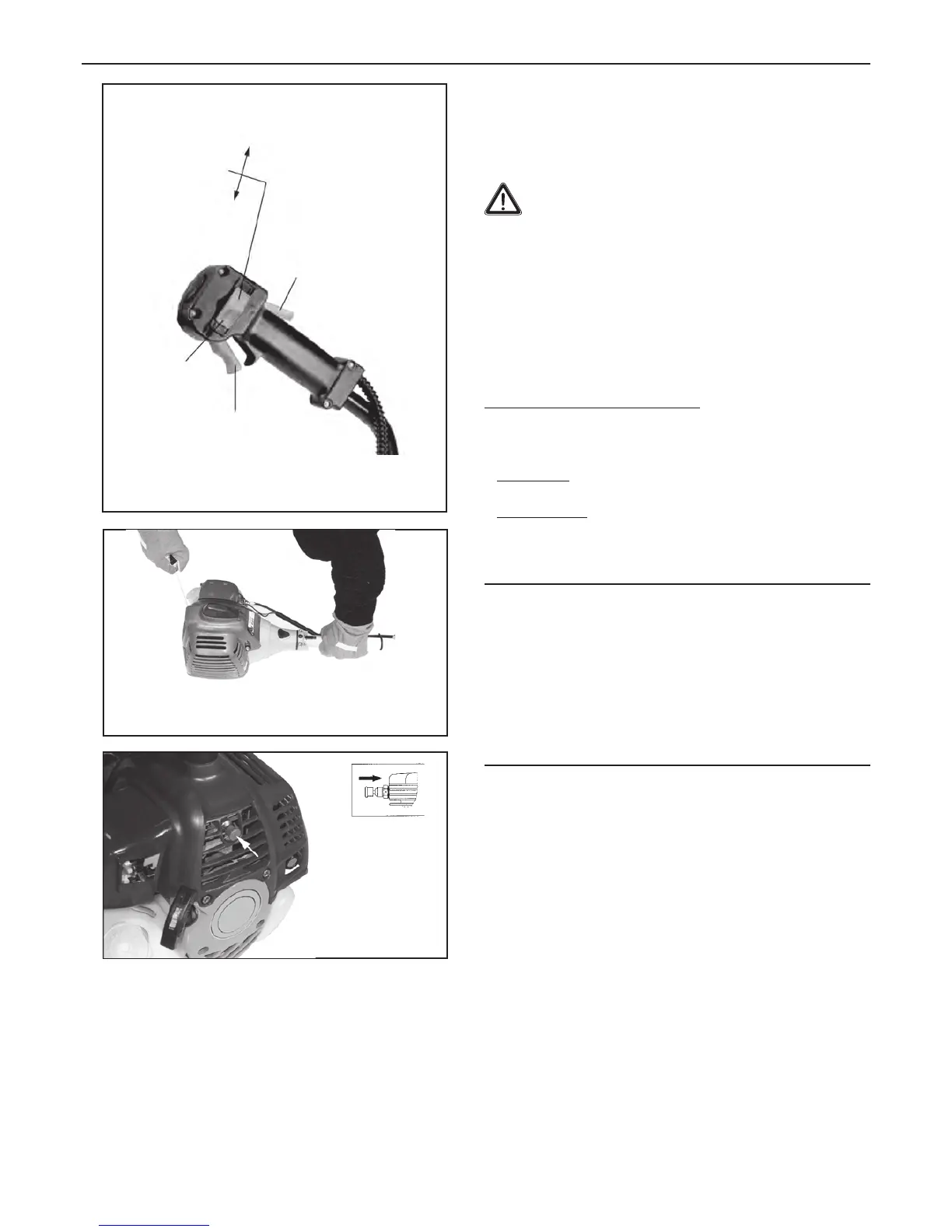

Fig. 21

Fig. 19

SEMIACCELERAZIONE

SEMIACCELERATION

POSIZIONE DI LAVORO

OPERATING POSITION

STOP

PULSANTE

BUTTON

LEVA ACCELERATORE

ACCELERATOR LEVER

GRILLETTO DI SI CU REZ ZA

SAFETY TRIGGER

Make sure that the cutting accessory has been securely

fastened in all its parts as described above and posi-

tioned in such way that the rotation direction in di ca tion

arrow and the safety messages (Fig. 18) are clearly

legible from above.

The disk can CAUSE SERIOUS DAMAGE AND

INJURY if not correctly positioned and locked

in place.

The fixed cup (or the adjustable support cup

OP TION AL) when positioned on the ground keeps the

cutting accessory raised during operation and per mits

cutting to be performed at a uniform height as long as

the rod is maintained at a constant in cli na tion. It also

prevents the cutting accessory from com ing into con tact

with the ground or small protruding stones.

Disk saws for deforestation:

Use only disk saws that conform to CE standards after

previously mounting the appropriate CE trunk re tain er

guard. These articles are supplied as OPTIONALS.

- Fastening: follow the instructions provided for the

fas ten ing of steel disks.

- Safety guard: always mount the appropriate CE trunk

retainer guard.

Both the disk saw and the CE trunk retainer guard

are pro vid ed as OPTIONALS.

Never use knives, blades or cutting elements other

than those provided by the manufacturer, and al ways

use only tools in per fect condition free of dents,

cracks, de for ma tion, or broken or worn-out teeth

that may cause the breakage of the cutting el e ment.

Given the high ro ta tion speed, broken piec es can fl y

off at tremendous speeds for se ri ous risks of dam-

age and injury for which the man u fac tur er declines

all responsibility.

4. STARTING

4.1 Introduction

The machine is provided with a set of “safety

guards” for your protection; make sure that they

are all in place and in good working order before

starting the machine.

4.2 Fuel

- The brushcutters have been designed for operation

with both premium grade fuel and lead-free petrol. When

using lead-free petrol, we recommend using synthetic oil

specifi cally formulated for two-stroke engines subjected

to high stress to be mixed in the percentage indicated

on the packaging (usually 2%).

Whenever mineral or semi-synthetic oils are used, the

percentage of oil must be 5%.

The use of synthetic oil specifi cally formulated for two-

stroke engines reduces the formation of fuel ash and

deposits both on the spark plug and piston and in the

cylinder and muffl er, and the emission of exhaust as

well.

Loading...

Loading...