Power Train Disassembly & Assembly

Adjusting Preload of Pinion

Bearings

Specifications

• New pinion bearings – torque

– 5 to 45 lb-in (0.56-5.08 N•m)

• Used pinion bearing in good condition – torque

– 10 to 30 lb-in (1.13-3.39 N•m)

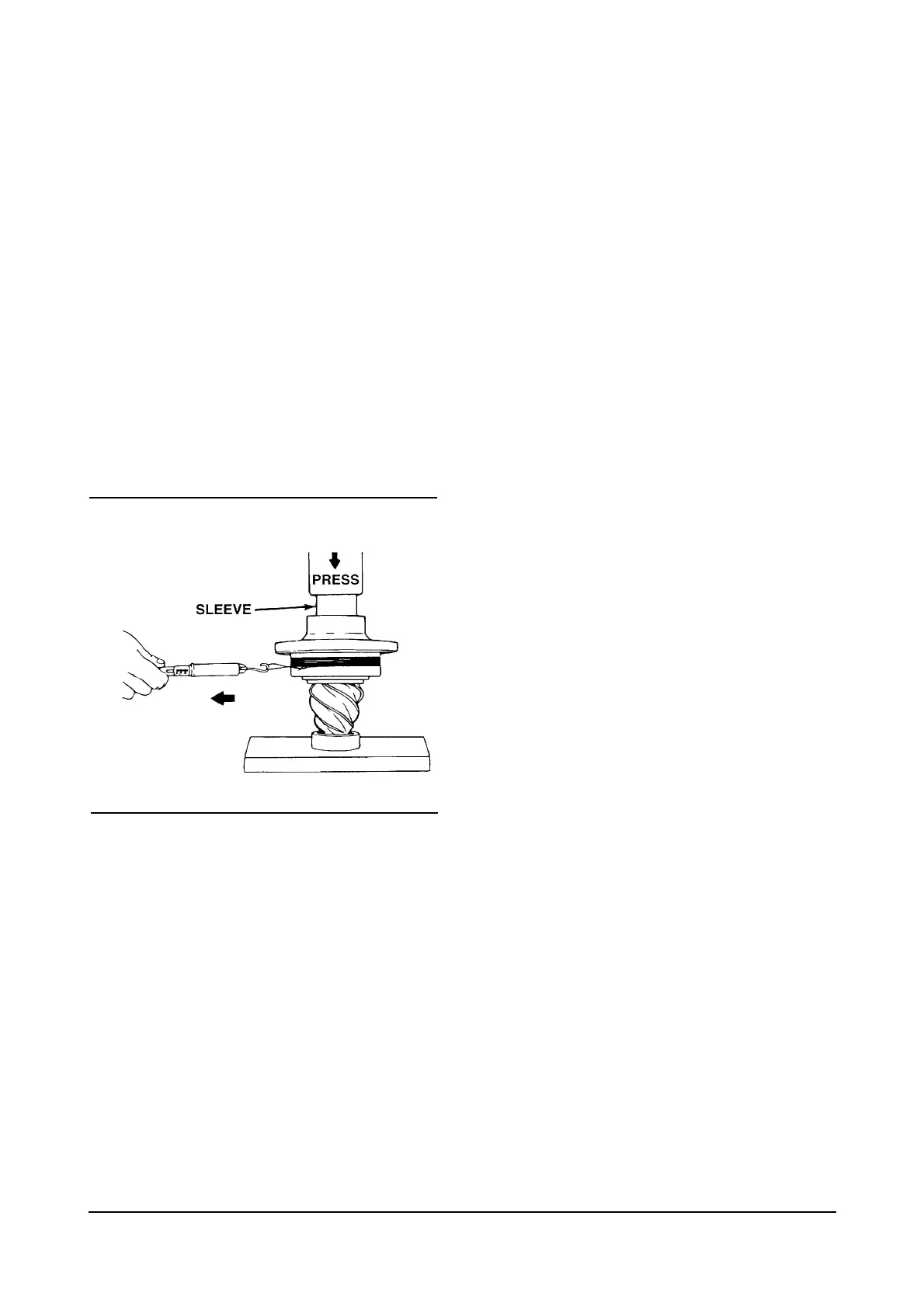

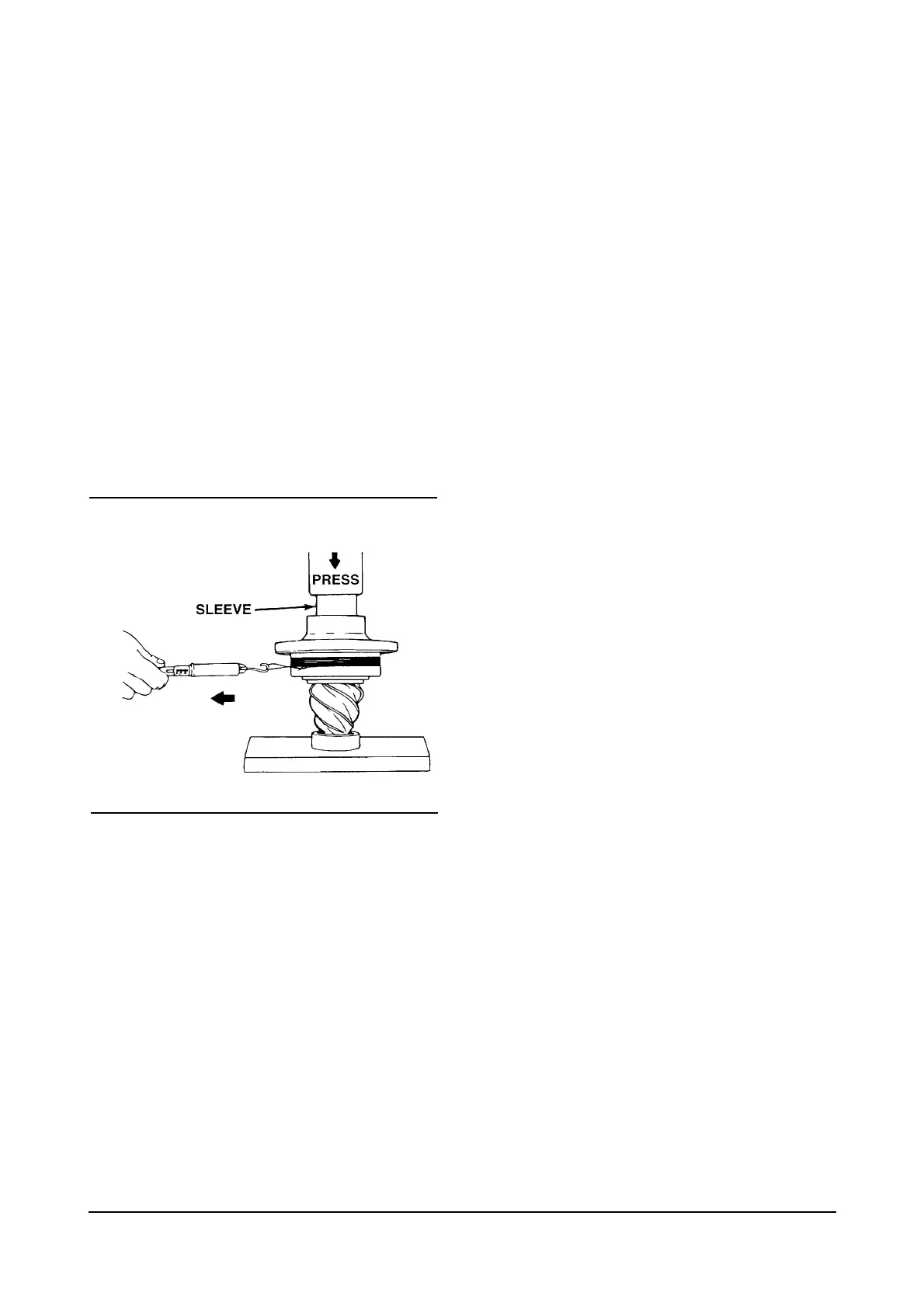

Press Method

NOTE : If a press is not available, or the press does

not have a pressure gauge, use the yoke method to

adjust pinion bearing preload.

a. Place the drive pinion and cage assembly in a

press, gear head (teeth) toward the bottom.

b. Install a sleeve of the correct size against the

inner race of the outer bearing.

c. Apply and hold the correct amount pressure to the

pinion bearings. (Press pressure needed on

bearings for correct preload : 54,000 lbs (24,494

kg)). As pressure is applied rotate the bearing

cage several times so that bearings make normal

contact.

d. While pressure is held against the assembly, wind

a cord around the bearing cage several times.

e. Attach a spring scale to the end of the cord.

f. Pull the cord with scale on a horizontal line. As the

bearing cage rotates, read the value inducated on

scale. Write down and record the reading.

NOTE : Do not read starting torque. Read only the

torque value after the cage starts to rotate. Starting

torque will give a false reading.

20

Loading...

Loading...