Power Train Disassembly & Assembly

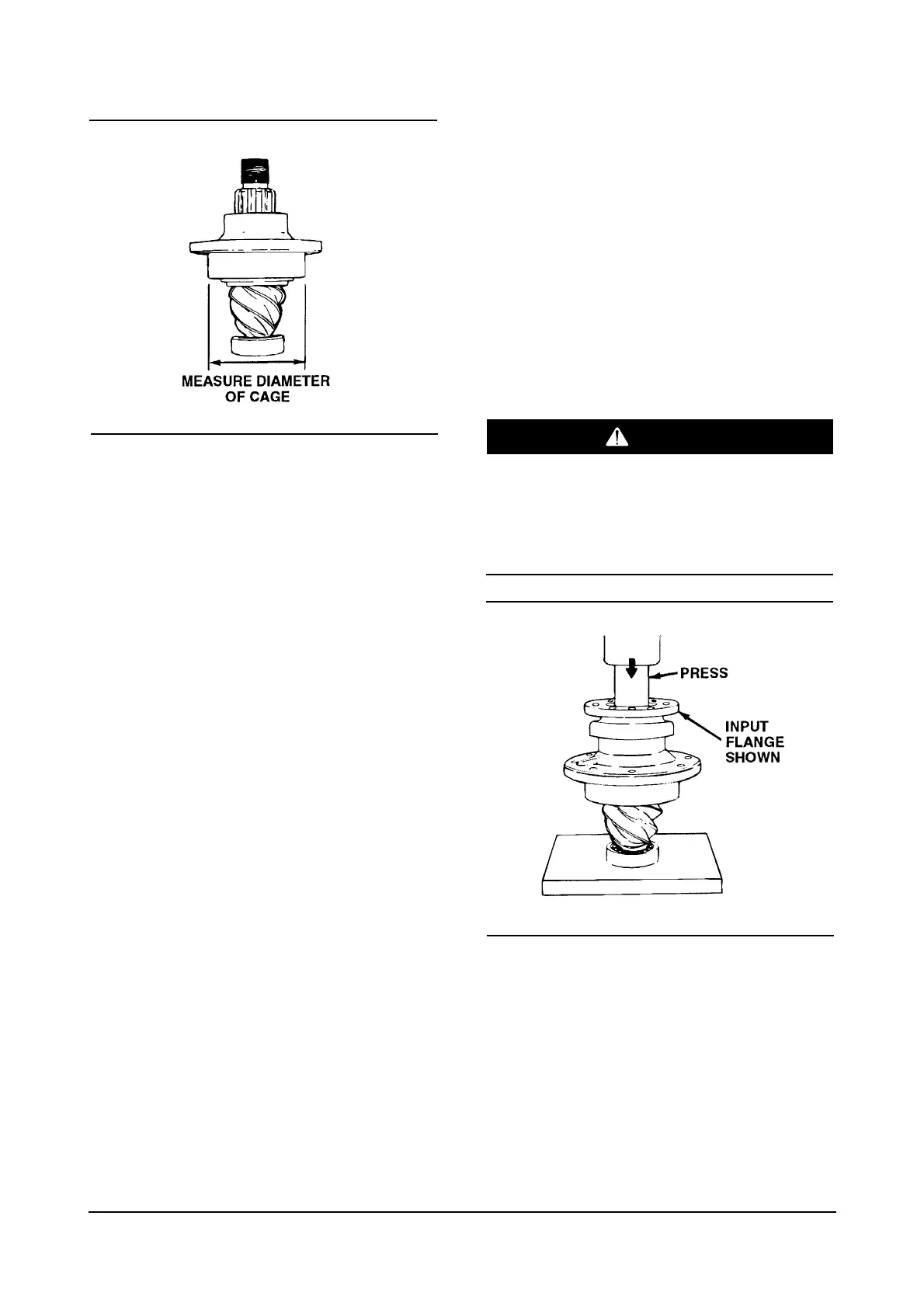

g. Measure the diameter of bearing cage where the

cord was wound. Measure in inches or

centimeters.

h. Divide the dimension in half to get the radius.

Write down and record the radius dimension.

i. Use the following procedure to calculate the

bearing preload (torque).

•

Pounds Pulled x Radius (inches) = lb-in Preload

– Preload x 0.113 = N•m Preload

•

Kilograms Pulled x Radius (cm) = kg - cm Preload

– Preload x 0.098 = N•m Preload

or

Examples

•

Reading from spring scale = 7.5 pounds (3.4 kg)

•

Diameter of bearing cage = 6.62 inches (16.8 cm)

•

Radius of bearing cage = 3.31 inches (8.4 cm)

7.5 lb x 3.31 in. = 24.8 in•lb Preload

Preload x 0.113 = 2.8 N•m Preload

or

3.4 kg x 8.4 cm = 28.6 kg•cm Preload

Preload x 0.098 = 2.8 N•m Preload

j. If the preload (torque) of pinion bearings is not

within specifications, do the following procedure

then repeat steps a through i.

To increase preload, install a thinner bearing

spacer. To decrease preload, install a thicker

bearing spacer.

k. Inspect the bearing preload with the drive pinion

and cage assembly installed in the carrier. Follow

the procedures to adjust preload of pinion

bearings, yoke method.

Yoke Method

Observe all WARNINGS and CAUTIONS provided

by the press manufacturer concerning press

operation to avoid serious personal injury and

possible damage to components during assembly

and installation procedures.

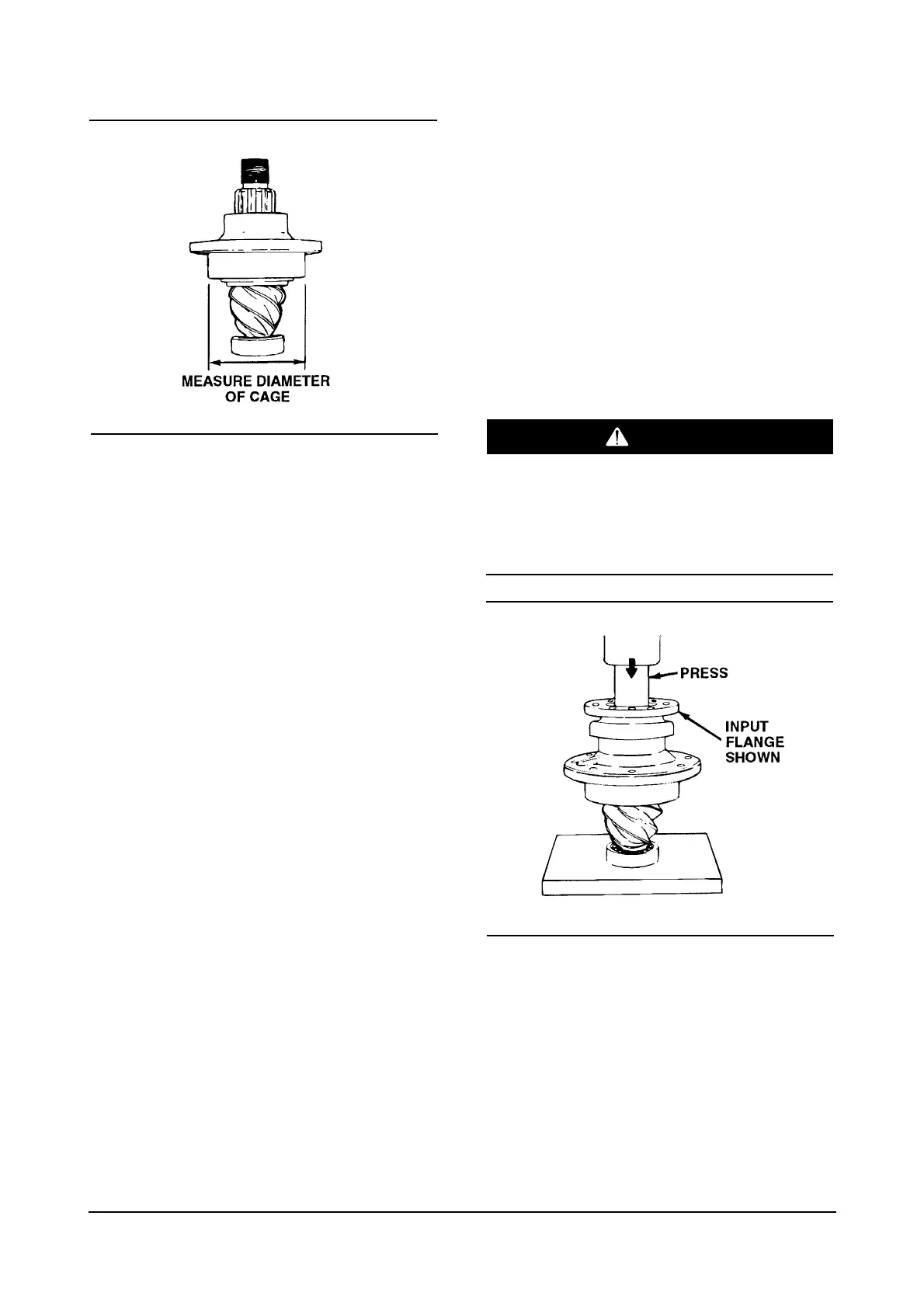

a. Install the input yoke, nut and washer on the drive

pinion. The yoke must be seated against the outer

bearing.

NOTE : Use a press to install the yoke.

Loading...

Loading...