Power Train Disassembly & Assembly

CAUTION : Do not install tight fit yokes on shafts

using a hammer or mallet. A hammer or mallet will

damage the yoke.

b. Temporarily install the drive pinion and cage

assembly in the carrier. Do not install shims under

the bearing cage.

c. Install the bearing cage to carrier capscrews.

Washers are not required at this time. Tighten the

capscrews by hand until snug.

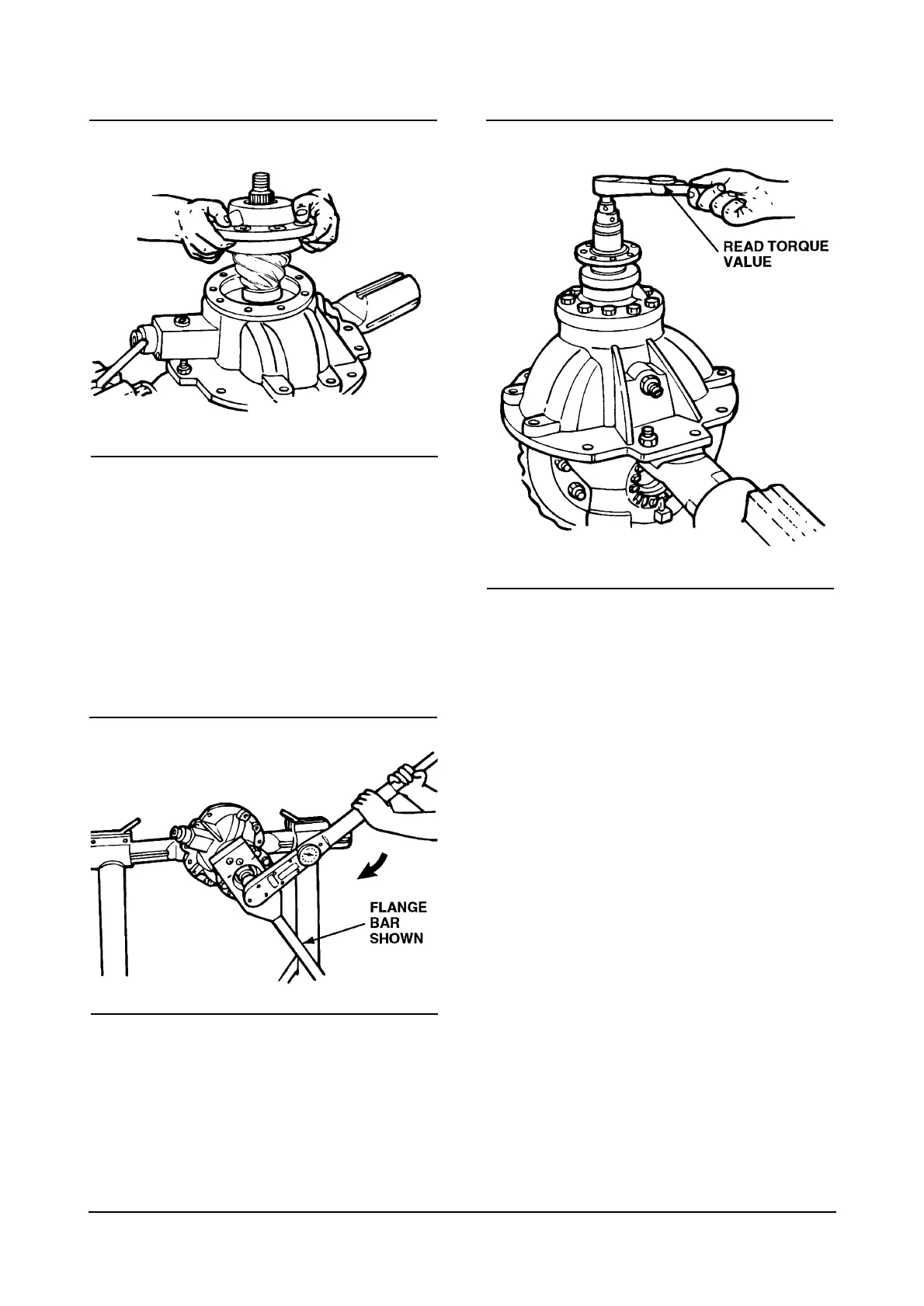

d. Fasten a yoke bar to the input yoke. The bar will

hold the drive pinion in position when the nut is

tightened.

e. Tighten the nut on drive pinion to a torque of 922

to 1132 lb•ft(1250 to 1535 N•m).

f. Remove the yoke bar.

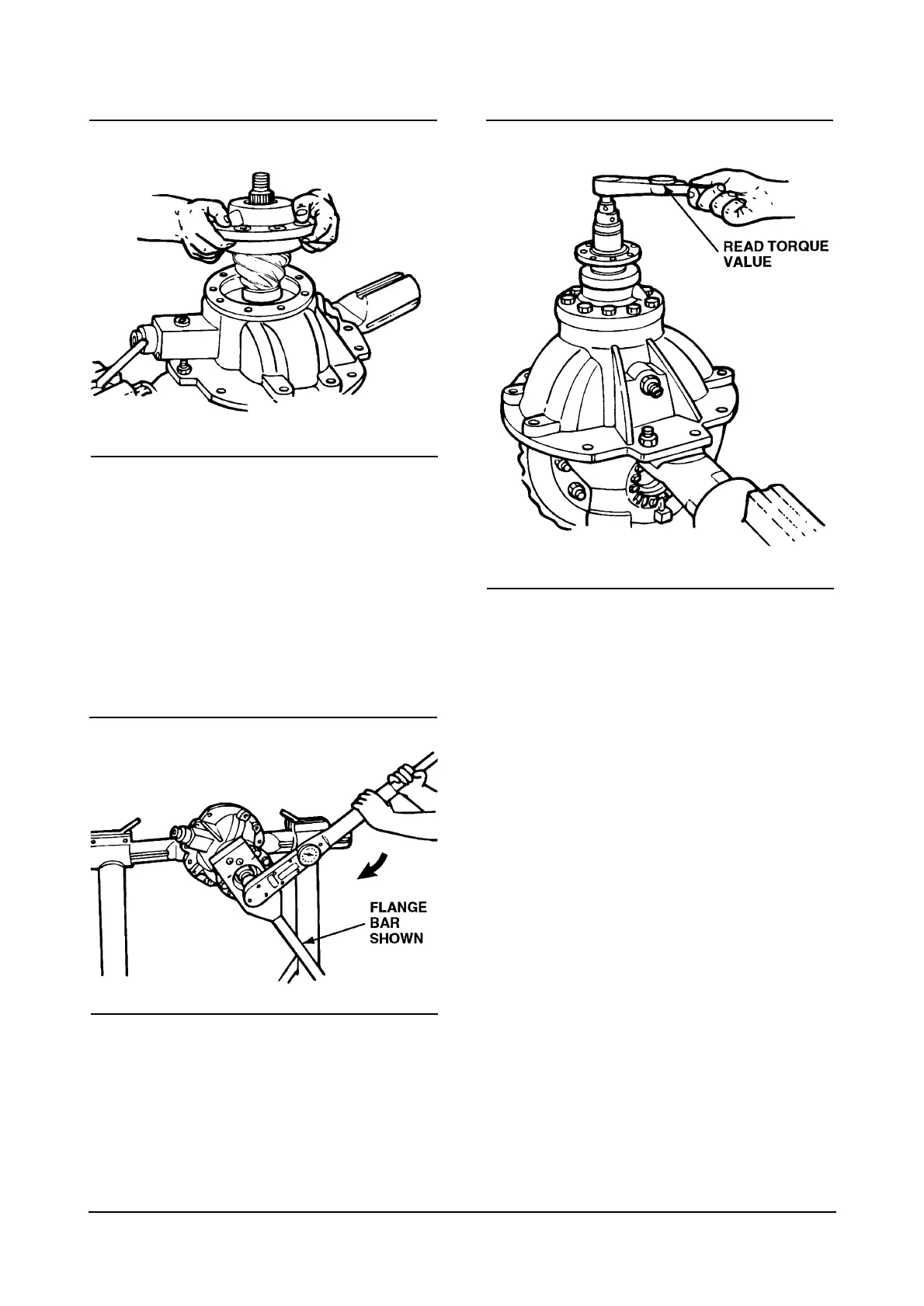

g. Attach a torque wrench on the drive pinion nut.

Rotate the drive pinion and read the value

inducated on torque wrench.

h. If the preload (torque) of pinion bearings is not

within specifications, remove the pinion and cage

assembly from carrier. Do the following procedure

then repeat steps a through g.

•

To increase preload, install a thinner bearing

spacer.

•

To decrease preload, install a thicker bearing

spacer.

10. After adjusting preload of pinion bearings,

remove the drive pinion and bearing cage from

carrier. Follow steps 1-5 on page 14-15.

22

Loading...

Loading...