Power Train Disassembly & Assembly

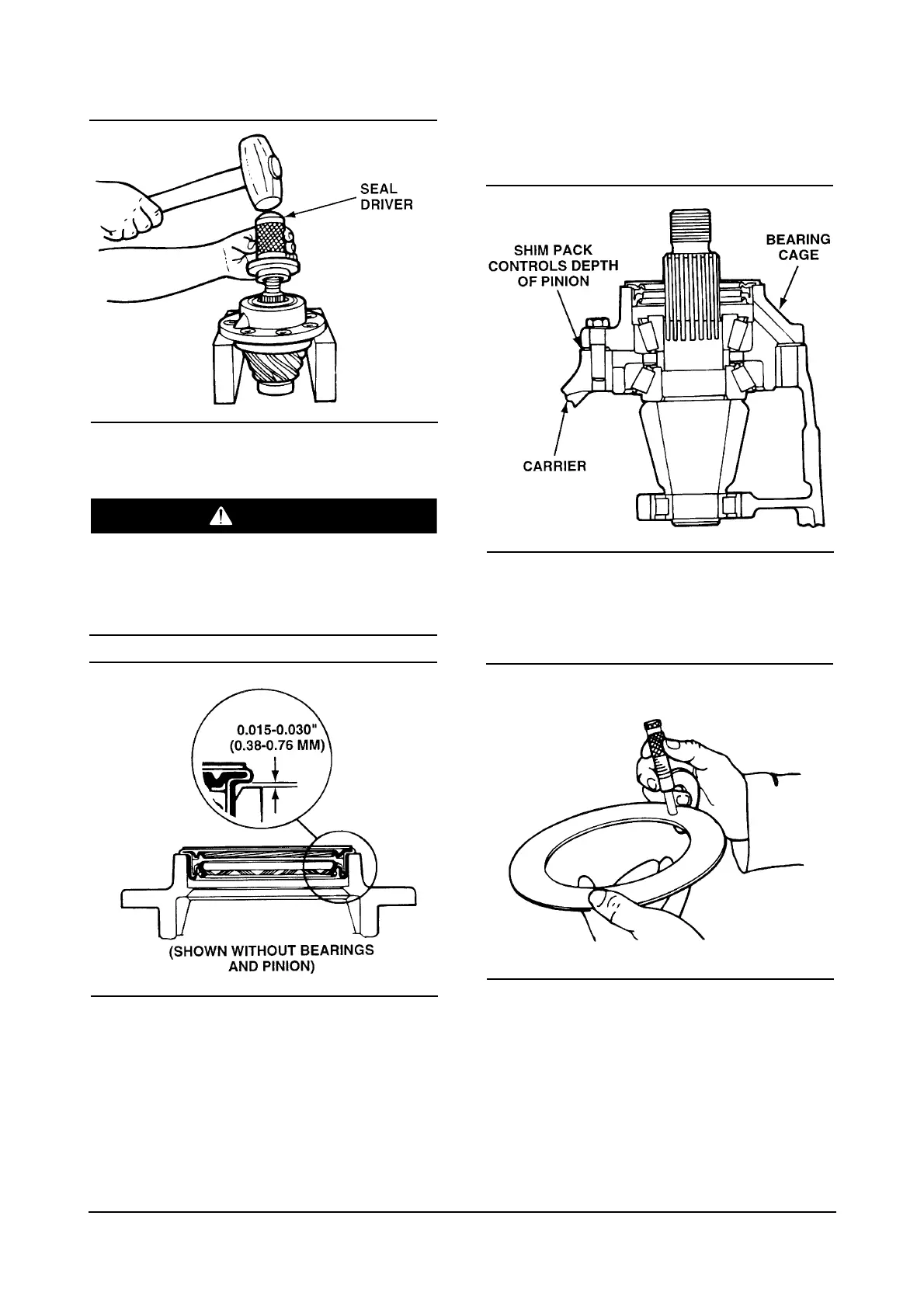

NOTE : If a press is not available, use a mallet and

the sleeve or driver to install the seal.

Do not hit steel parts with a steel hammer during

removal and disassembly procedures. Striking

parts with a hammer can cause the parts to break

and result in serious personal injury.

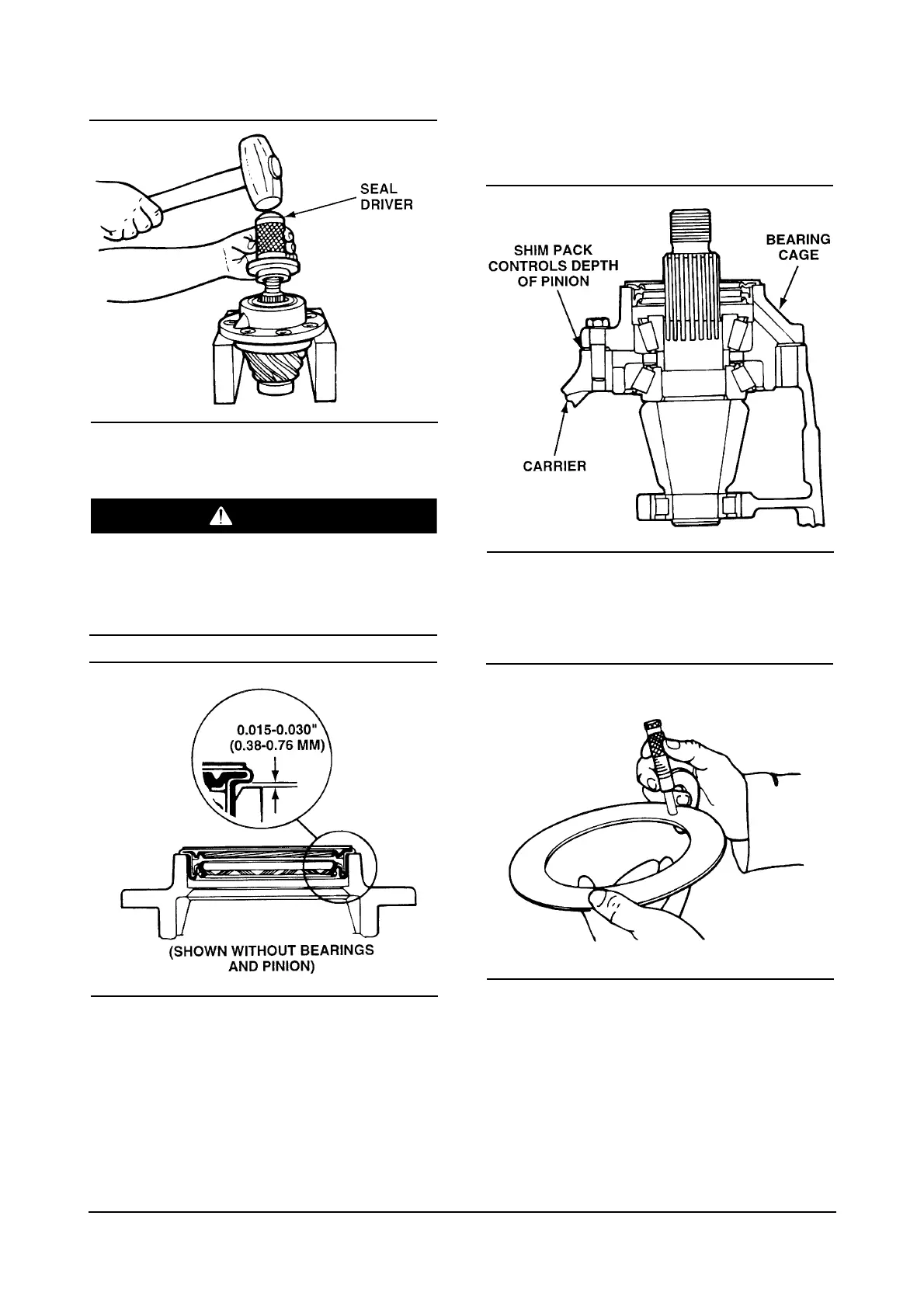

d. After the triple-lip seal is installed, a gap of

apporximately 0.015 to 0.030 inch (0.38-0.76 mm)

between the flange and bearing cage is normal.

Inspect the gap with a feeler gauge at several

points around the seal. The gap must be within

0.015 to 0.030 inch (0.38-0.76 mm). The

difference between the largest and smallest gap

measurement must not exceed 0.010 inch (0.254

mm).

Adjusting Shim Pack Thickness for

a New Drive Pinion (Depth of Pinion)

NOTE : Use this procedure if a new drive pinion and

ring gear set is installed, or if the depth of the drive

pinion has to be adjusted.

1. Measure the thickness of the old shim pack that

was removed from under the pinion cage with a

micrometer. Record the measurement for use later.

Loading...

Loading...