Power Train Disassembly & Assembly

4. Measure the distance X or Y again. Compare the

dimension with the distance X or Y measured in

step 2. The difference between the two dimensions

is the amount the bearing caps have expanded

(leg spread).

Example

•

Distance X or Y

– Before tightening adjusting rings = 13.927 inch

(353.740 mm).

•

Distance X or Y

– After tightening adjusting rings = 13.936 inch

(353.970 mm)

•

13.936 inch – 13.927 inch = 0.009 inch (0.230 mm)

difference.

If the dimension is within speciffications, continue by

inspecting runout of the ring gear. If the dimension is

less than specifications, repeat steps 3 and 4 as

needed.

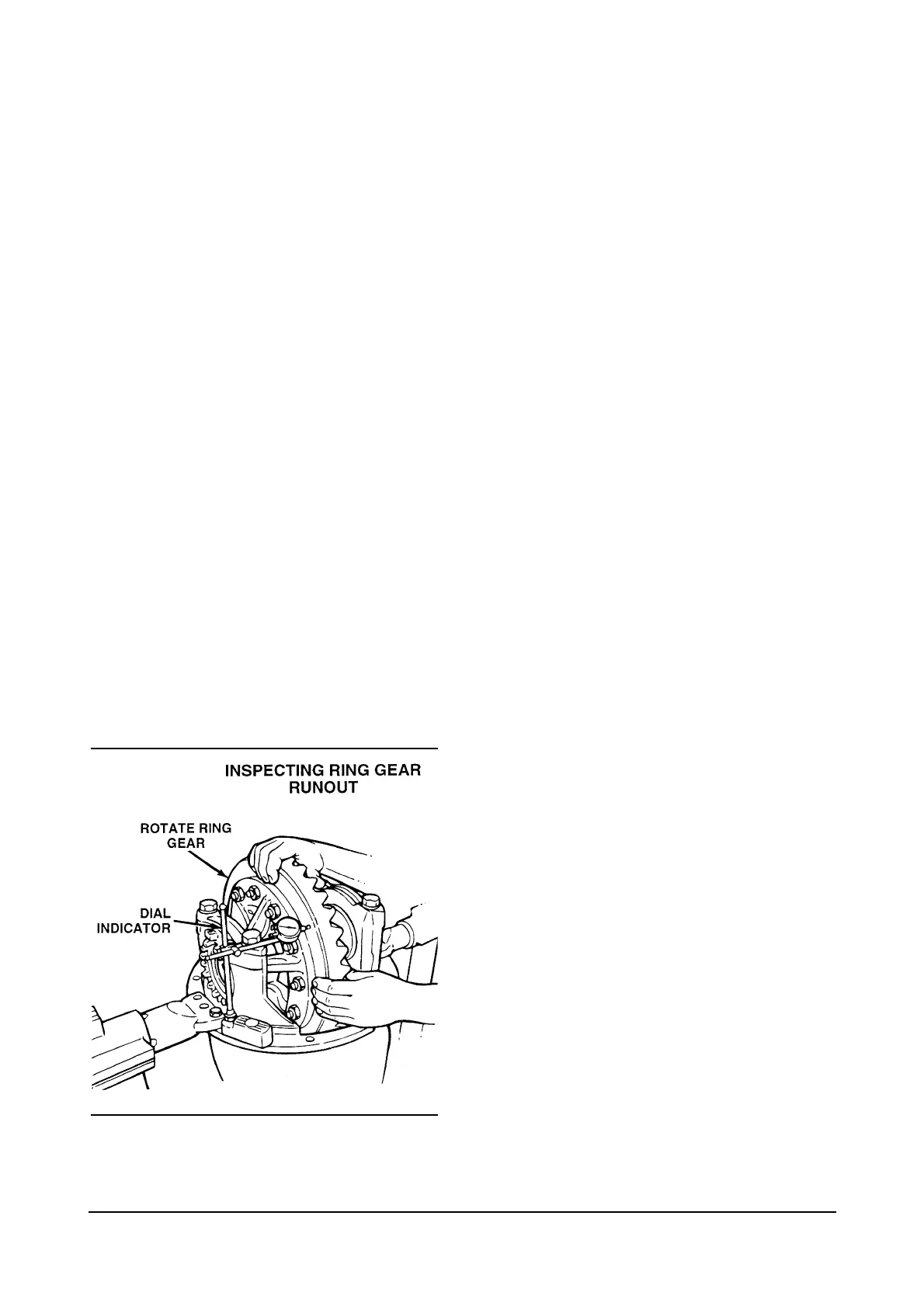

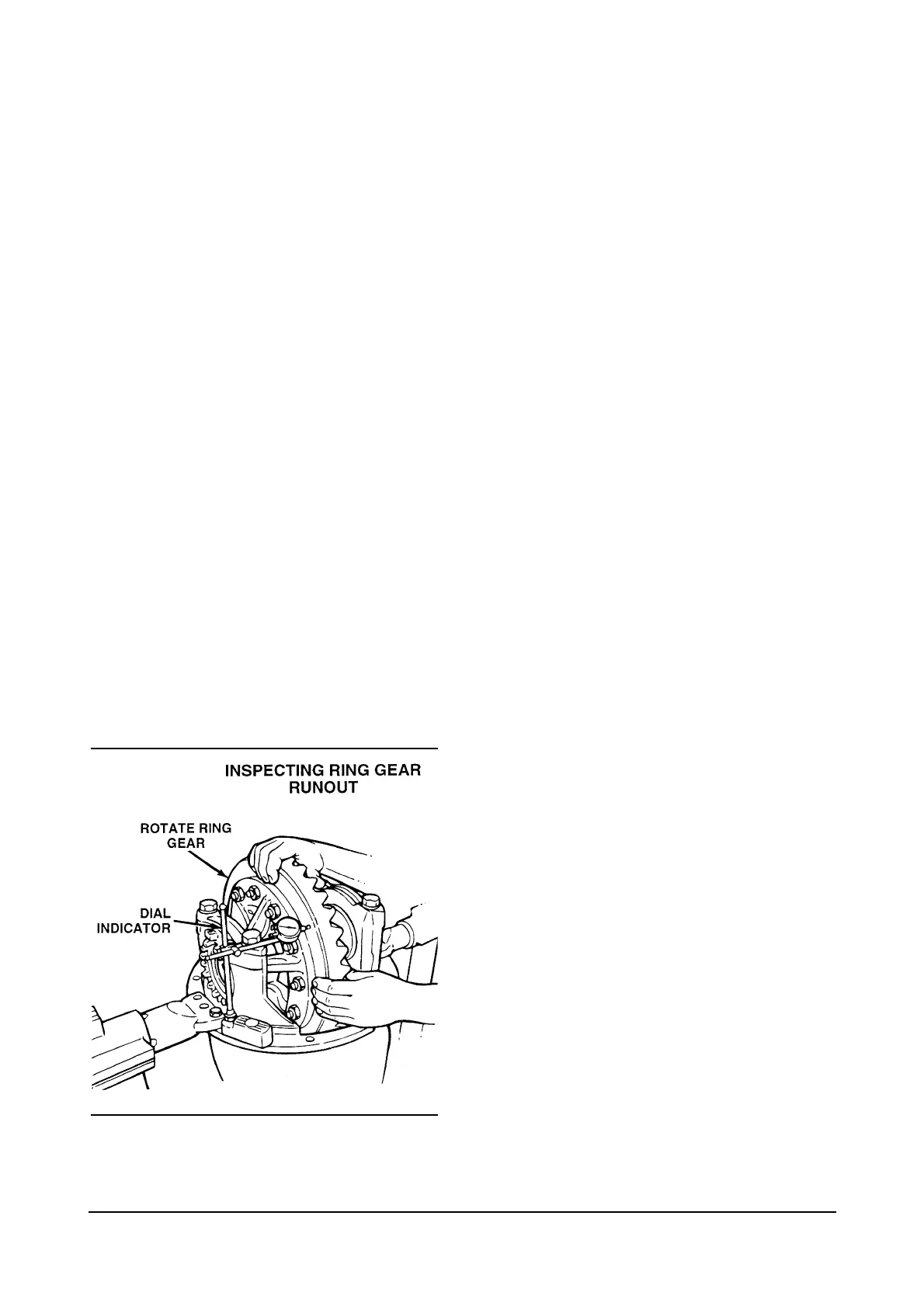

Checking the Runout of the

Ring Gear

Runout Specification

•

0.008 inch (0.200 mm)

1. Attach a dial indicator on the mounting flange of

the carrier.

2. Adjust the dial indicator so that the plunger or

pointer is against the back surface of the ring gear.

3. Set the dial indicator to zero (0).

4. Rotate the differential and ring gear and read the

dial indicator. The runout of the ring gear must not

exceed 0.008 inch (0.200 mm).

If runout of the ring gear exceeds this

specification, remove the differential and ring gear

assembly from the carrier. Refer to and preform

the disassembly procedure on page 11 and then

the following steps 5 and 6.

5. Inspect the differential parts including the carrier

for the problem that causes the runout of gear to

exceed specifications. Always replace defective

parts.

6. After the parts are repaired or replaced, install the

differential and ring gear into the carrier. Refer to

the procedure on page 32.

7. Repeat the procedure for preload adjustment of

differential bearings.

Ring Gear Backlash Adjustment

Specifications

– Range of backlash setting: 0.008 to 0.018 inch

(0.200-0.460 mm).

– Backlash setting for new gear sets: 0.012 inch

(0.300 mm)

If the old gear set is installed, adjust the backlash to

the setting that was measured before the carrier was

disassembled.

If a new gear set is installed, adjust the ring gear

backlash to the correct specification for a new gear

set.

After inspecting the tooth contact patterns, the

backlash can be adjusted within specification limits, if

needed. To change the location of the pattern use the

following procedures.

36

Loading...

Loading...