Power Train Disassembly & Assembly

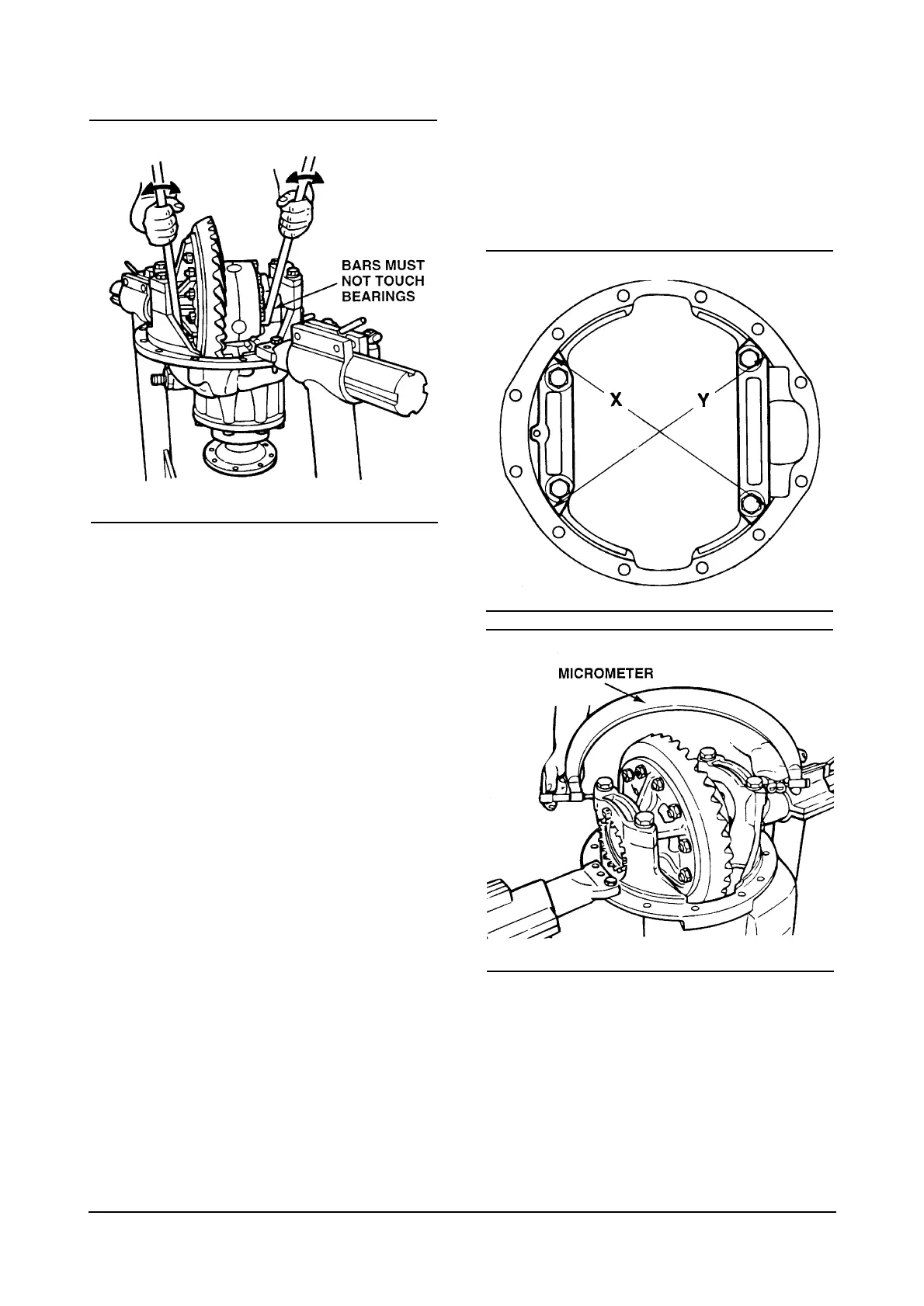

b. Use two pry bars between the differential case or

ring gear and the carrier at locations other than

described in step a. The pry bars must not touch

the differential bearings.

4. Tighten the same bearing adjusting ring so that no

end play shows on the dial indicator. Move the

differential and ring gear to the left and right as

needed. Repeat step a or b.

5. Tighten each bearing adjusting ring one notch from

the zero end play measured in step 4.

6. Continue by inspecting runout of the ring gear.

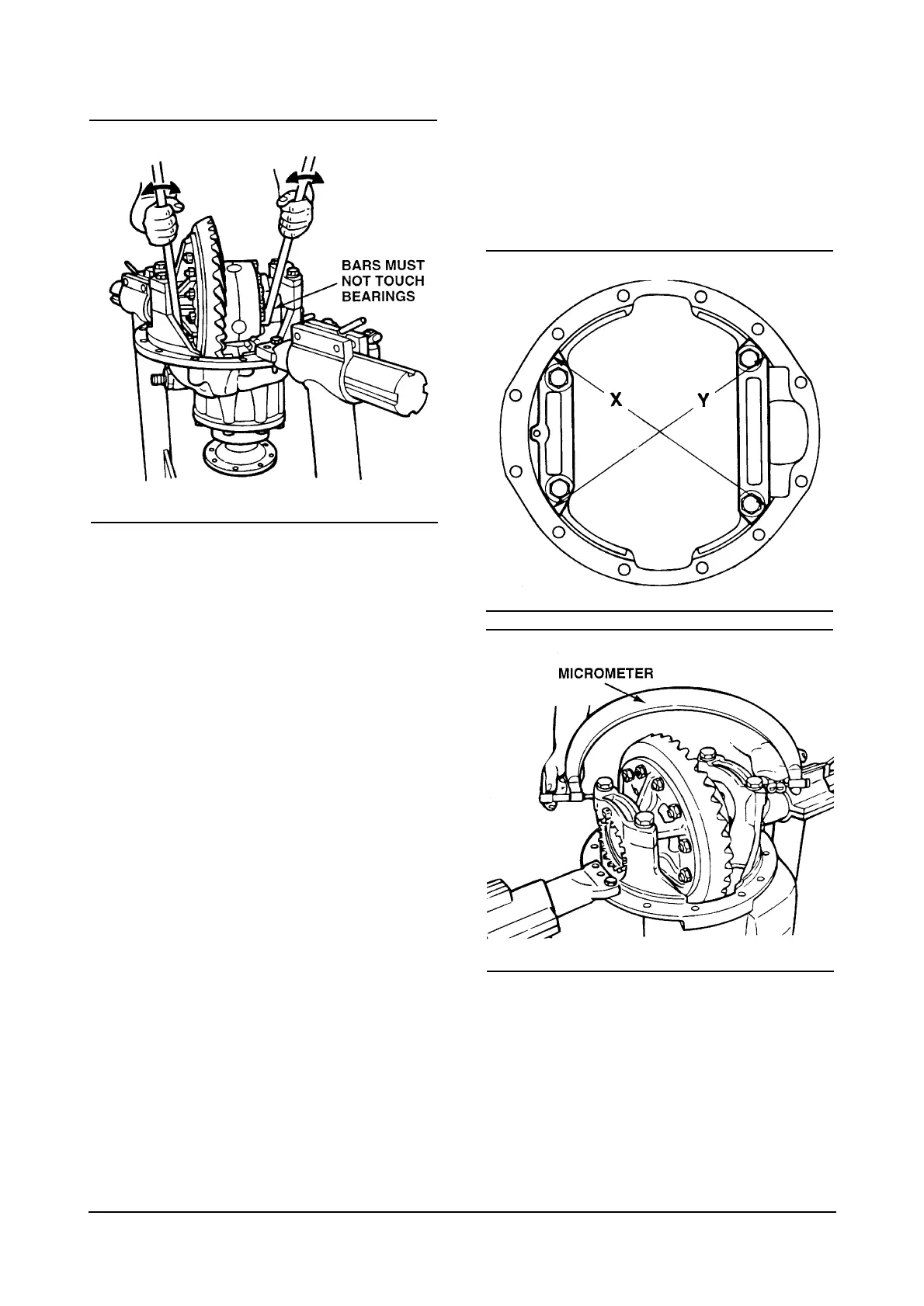

Large Micrometer Method

A second method of inspecting preload is to measure

the expansion between the bearing caps (leg spread)

after the adjusting rings are tightened. Use the

following procedure.

1. Turn both adjusting rings hand tight against the

differential bearings.

2. Measure the distance X or Y between opposite

surfaces of the bearing caps. Use a large

micrometer of the correct size. Record the

measurement.

3. Tighten each bearing adjusting ring one notch.

35

Loading...

Loading...