Power Train Disassembly & Assembly

Adjust Preload of Differential

Bearings

Specifications

•

Preload of differential bearings

– 15 to 35 lb-in (1.7-3.9 N•m) torque.

•

Expansion between bearing caps (leg spread)

– 0.002 to 0.009 inch (0.050-0.229 mm)

Dial Indicator Method

Use the dial indicator or the large micrometer method

for checking and adjusting the preload of the main

differential side bearings.

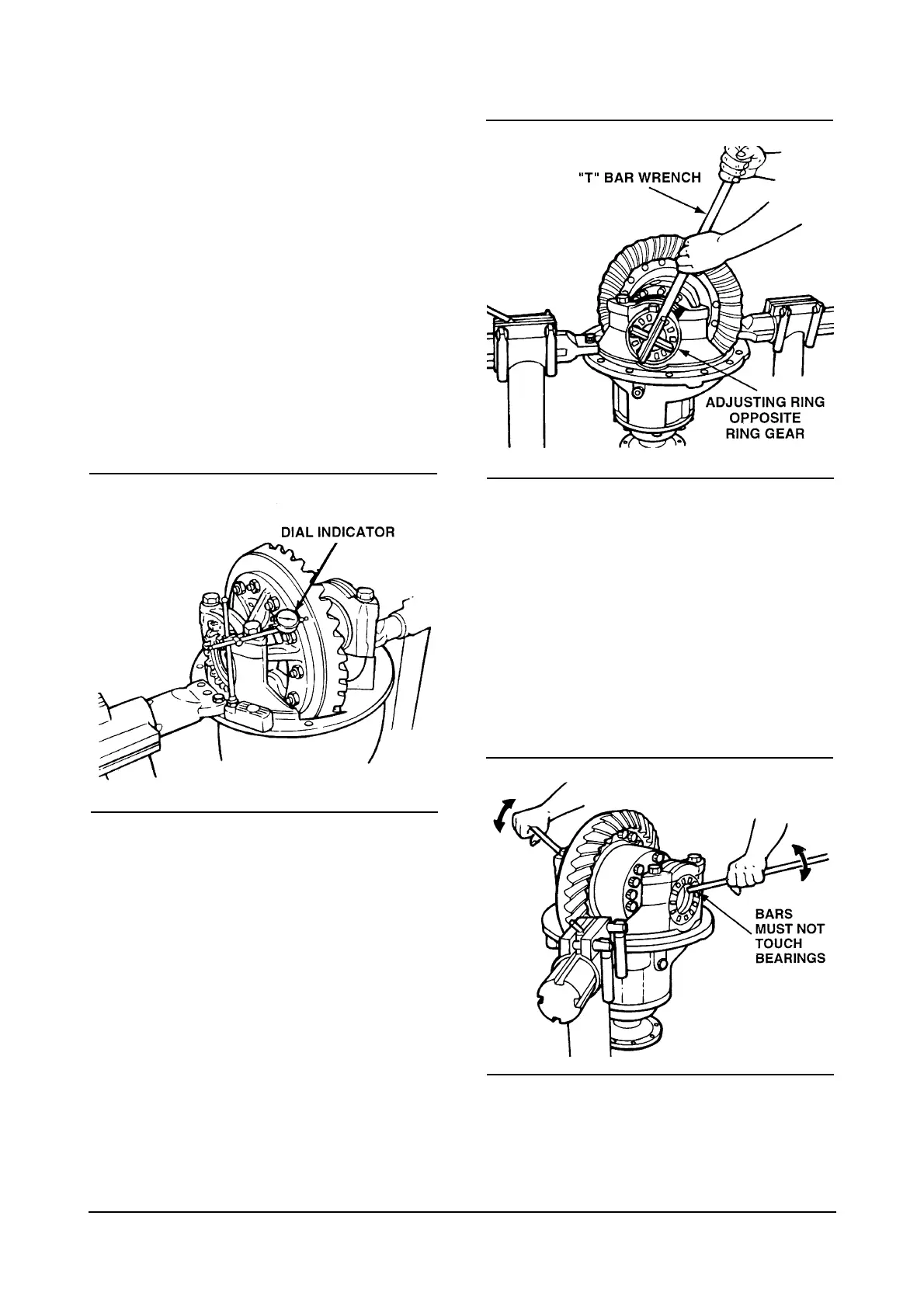

1. Attach a dial indicator on the mounting flange of

the carrier.

2. Adjust the dial indicator so that the plunger or

pointer is against the back surface of the ring gear.

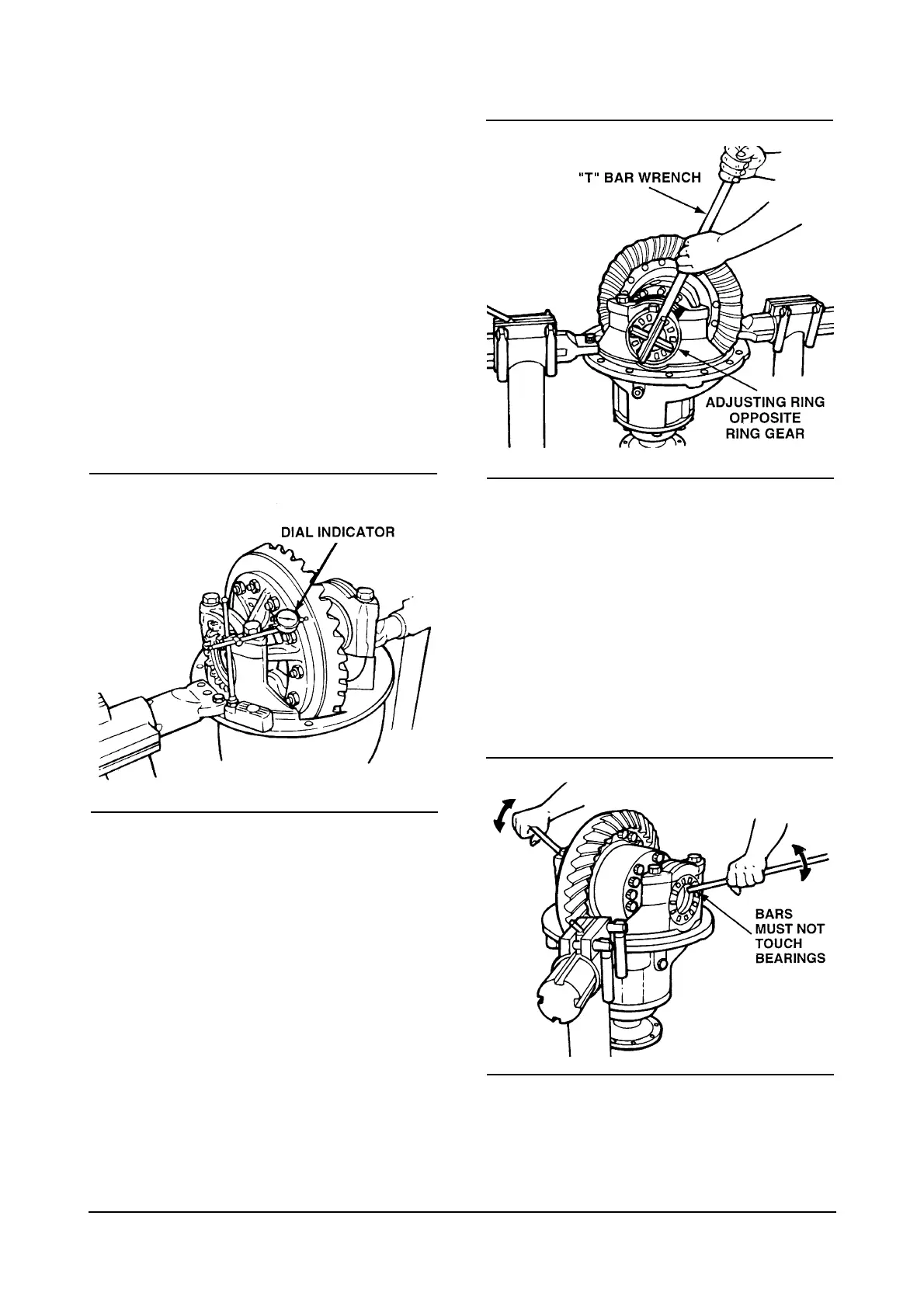

CAUTION : When turning the adjusting rings, always

use a tool that engages two or more opposite

notches in the ring. A “T” bar wrench can be used for

this purpose. If the tool does not correctly fit into the

notches, damage to the lugs will occur.

3. Loosen the bearing adjusting ring that is opposite

the ring gear so that a small amount of end play

shows on the dial indicator. Move the differential

and ring gear to the left and right with pry bars

while you read the dial indicator. Use the following

step a or b.

a. Use two pry bars that fit between the bearing

adjusting rings and ends of the differential case to

check preload. The pry bars must not touch the

differential bearings.

34

Loading...

Loading...