Power Train Disassembly & Assembly

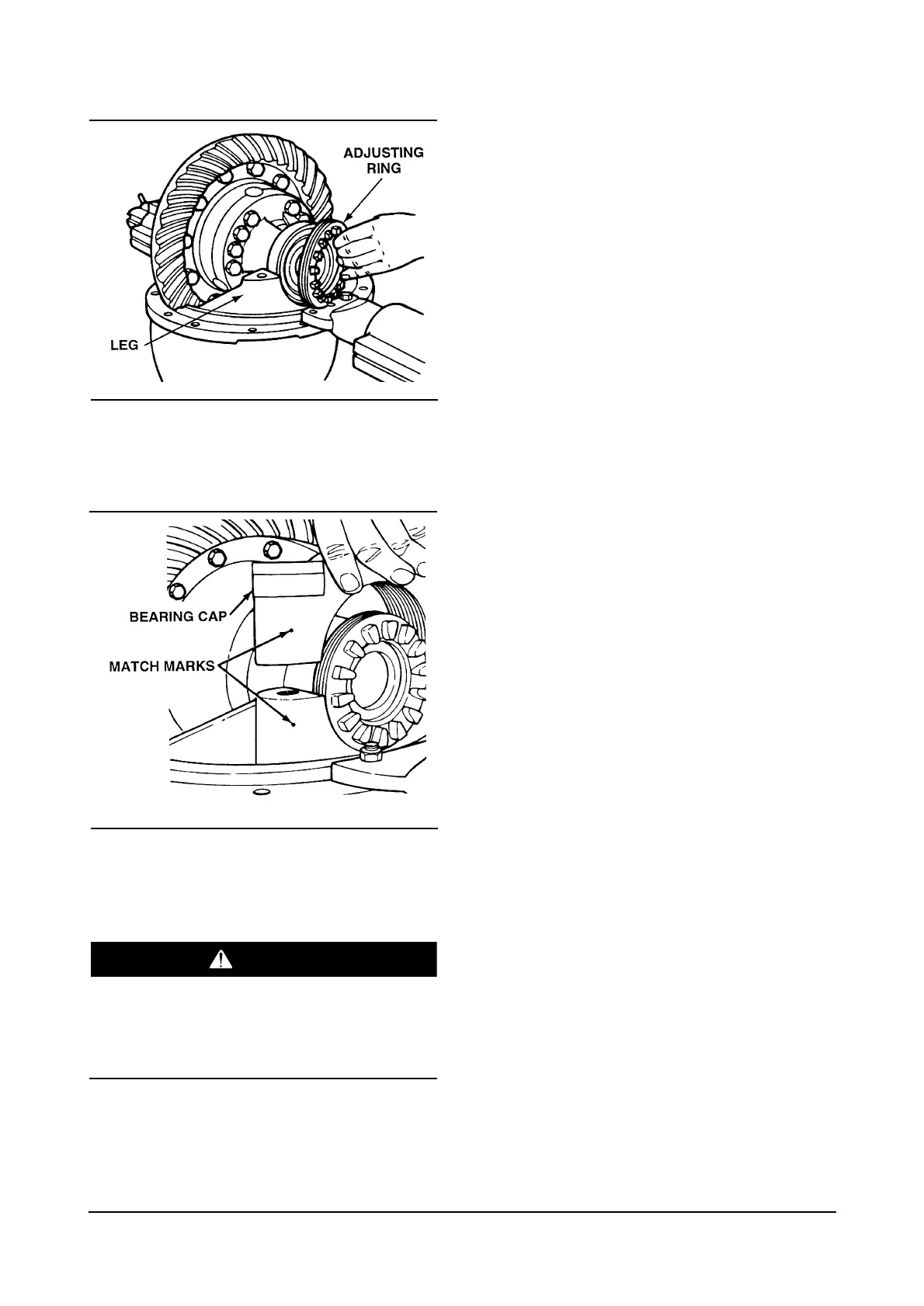

6. Install both of the bearing adjusting rings into

position between the carrier legs. Turn each

adjusting ring hand-tight against the bearing cup.

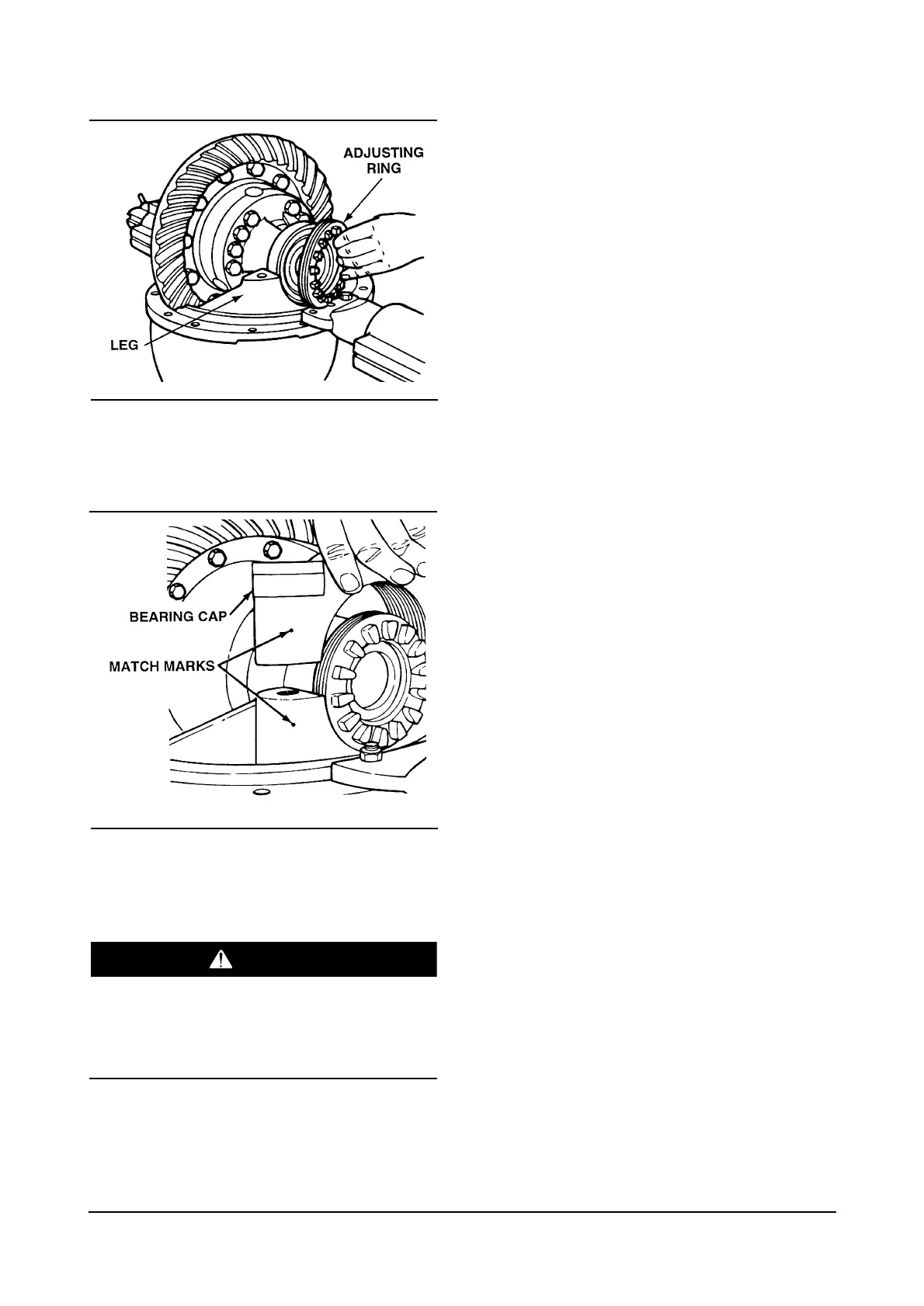

7. Install the bearing caps over the bearings and

adjusting rings in the correct location as marked

before removal.

Do not hit steel parts with a steel hammer during

removal and disassembly procedures. Striking

parts with a hammer can cause the parts to break

and result in serious personal injury.

8. Seat each bearing cap with a light leather, plastic

or rubber mallet. The caps must fit easily against

the bearings, adjusting rings and carrier. DO not

force the bearing caps into position.

CAUTION : If bearing caps are not installed in

correct locations, the bores and threads in caps will

not match the carrier. You will have problems

assembling the caps on the carrier and damage to

parts can occur. Do not force the bearing caps into

position.

9. If bearing caps do not correctly fit into position,

inspect the alignment of match marks between

caps and carrier. Remove the caps and repeat

steps 6-8.

10. Install the capscrews and washers that hold

bearing caps to the carrier. Tighten the

capscrews by hand four to six turns, then tighten

the capscrews to a torque of 347 to 431 lb•ft (470

to 585 N•m).

NOTE : Do not install the cotter keys that hold the

bearing adjusting rings in position. Continue by

adjusting the preload of differential bearings, adjust

backlash of the hypoid gear and inspect tooth contact

patterns.

Loading...

Loading...