Power Train Disassembly & Assembly

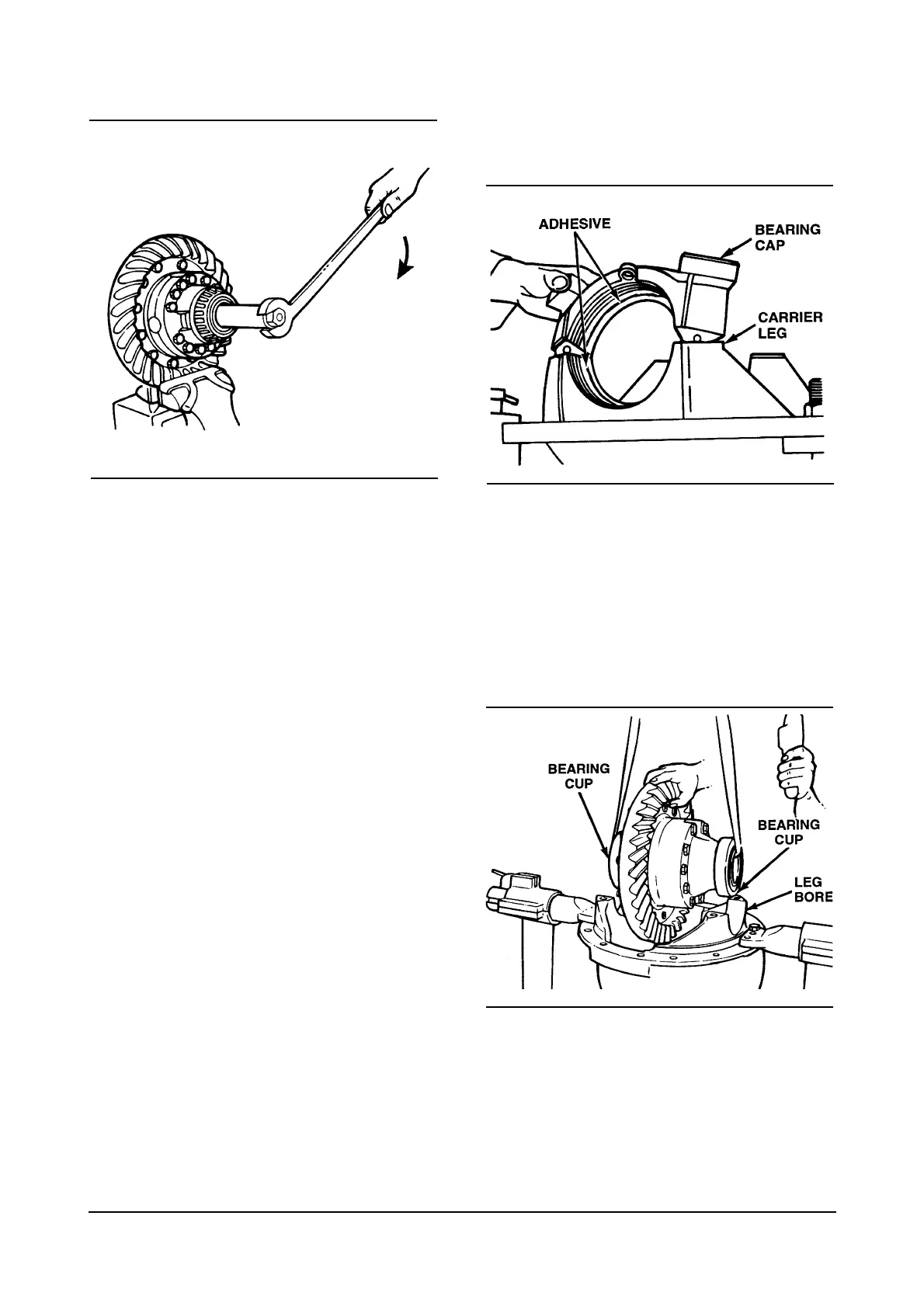

4. Attach a wrench to the nut of the tool and rotate

the differentail gears. The differential assembly

must freely rotate.

5. If the differentail assembly dose not freely rotate,

disassemble the differential gears from the case

halves.

6. Inspect the case halves, spider, gears and thrust

washers for the problem that causes the torque

value to exceed the specification. Repair or

replace parts.

7. After the parts are repaired or replaced, assemble

the parts and repeat steps 1 through 6.

Install the Differential and Ring Gear

Assembly

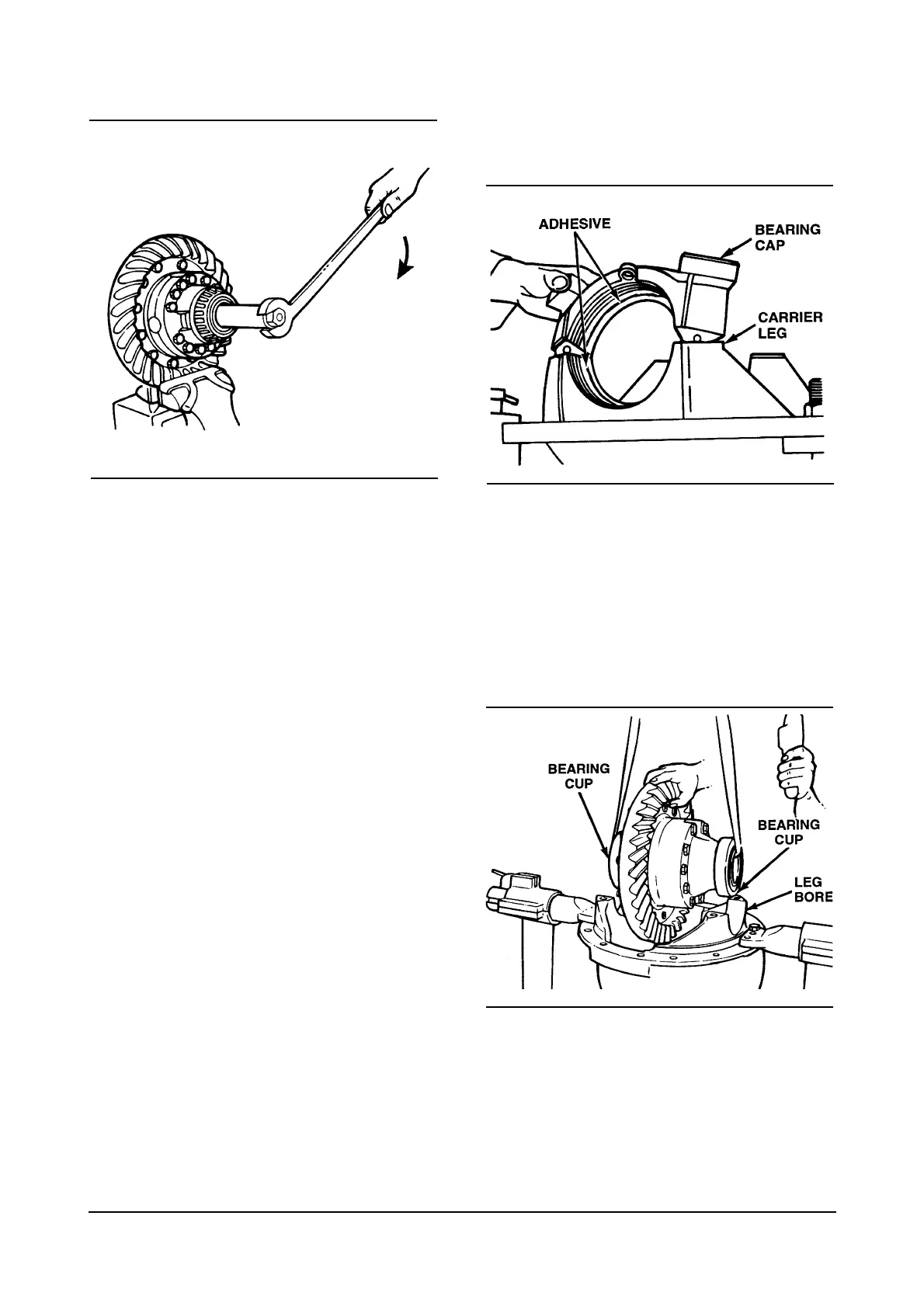

1. Clean and dry the bearing cups and bores of the

carrier legs and bearing caps.

2. Apply axle lubricant on the inner diameter of the

bearing cups and on both bearing cones that are

assembled on the case halves.

3. Apply Adhesive into the bearing bores of the

carrier legs and bearing caps. Make certain not to

allow adhesive to contact adjusting ring threads.

4. Install the bearing cups over the bearing cones

that are assembled on the case halves.

5. Safely lift the differentail and ring gear assembly

and install into the carrier. The bearing cups must

be flat against the bores between the carrier legs.

32

Loading...

Loading...