Power Train Disassembly & Assembly

Assemble the Spindle, Brake

Spider and Brake

To prevent serious eye injury, always wear safe

eye protection when you perform vehicle

maintenance or service.

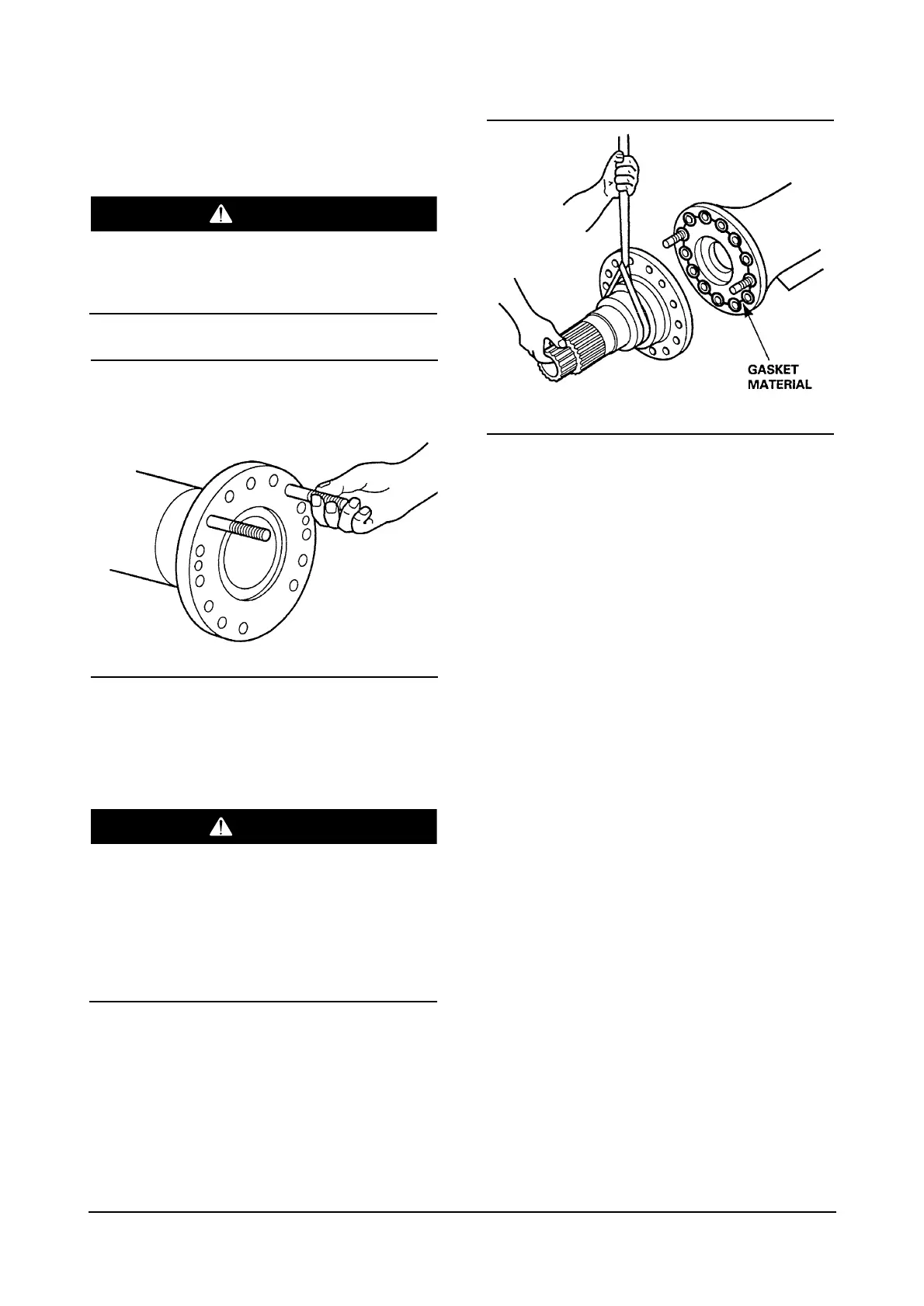

1. Install two temporary studs (0.75 inch-10 threads,

approximately 4 inches long) into the axle housing

flange. Install the studs at the 11 o’clock and 1

o’clock positions.

When you apply some silicone gasket materials,

small amounts of acid vapor are present. To

prevent possible serious injury, the work area

must be well-ventilated. If the silicone gasket

material gets into your eyes, flush them with water

for 15 minutes. Have your eyes checked by a

doctor as soon as possible.

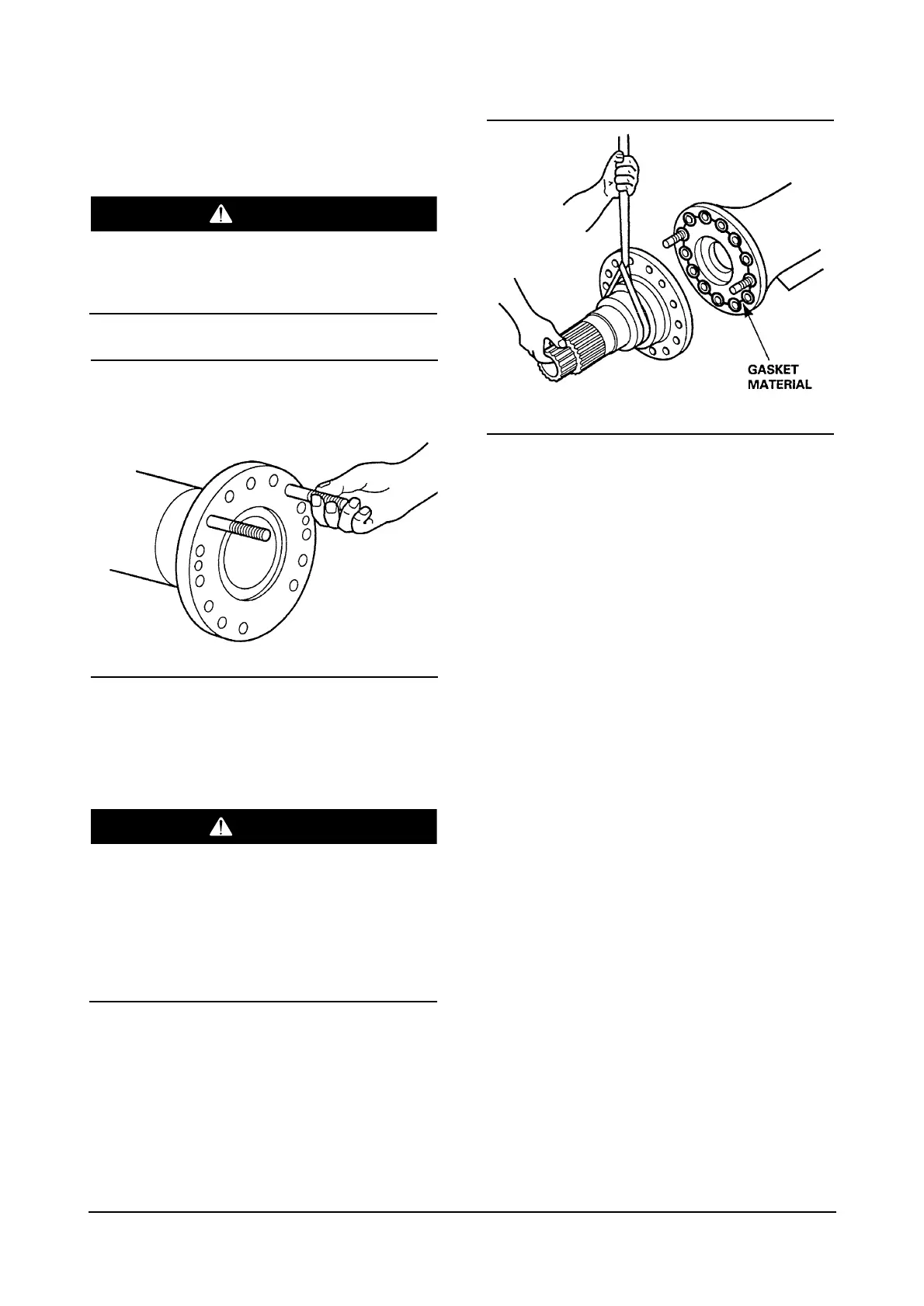

2. Apply a 0.125 inch (3.18 mm) diameter continuous

bead of silicone gasket material (Three Bond 1216

or Loctite 5699) around the flange mounting face

of either the axle housing or the spindle. Also

apply the gasket material around the edge of all

the fastener holes on that surface.

3. Align flange flats and install the spindle onto the

axle housing.

4. Install the brake spider onto the spindle (30).

5. Install and hand tighten some of the spindle

mounting capscrews (31) and washers (32).

6. Remove the two temporary studs.

7. Install the remaining spindle mounting capscrews

and washers. Tighten all capscrews and washers

to 375-430 lb•ft (508-583 N•m).

NOTE : Replace the camshaft bushing and grease

seals before the camshaft bracket is installed onto

the brake spider. Refer to the brake section of this

manual.

8. Install the brake camshaft bracket with the O-ring

on the pilot onto the brake spider.

9. Install the four mounting capscrews and washers.

Tighten the capscrews to 85-115 lb•ft (115-156

N•m).

Loading...

Loading...