Power Train Disassembly & Assembly

10. Install the brake camshaft bracket clamp around

the bracket tube and install the two capscrews

and washers that mount the clamp to the axle

housing. Tighten the capscrews to 35-50 lb•ft (47-

68 N•m).

NOTE : Refer to the brake section of this manual, to

install the brake camshaft, anchor pin components,

brake shoes, brake springs, slack adjusters and

related parts.

11. Install the air chamber to bracket mounting nuts.

Tighten the nuts to 100-115 lb•ft (136-156 N•m).

12. Attach the push rod yoke to the slack adjuster.

Tighten the yoke jam nut to 25-50 lb•ft (34-68

N•m).

13. Install the brake dust shield. Tighten the

mounting capscrews and washers to 35-50 lb•ft

(47-68 N•m).

Assemble the Wheel End

1. Press the new inner and outer bearing cups (27,

22) into the wheel hub (24).

2. Position the wheel hub (24) with the oil seal bore

facing UPWARD.

3. Apply axle gear lubricant to the bearing rollers and

install the inner wheel bearing cone (28).

CAUTION : Do not damage the hub oil seal bore

surface in the wheel hub. Damage to this surface will

result in oil leakage after assembly.

NOTE : Eliminate oil leakage from the outer diameter

of the seal by applying a light film of non-hardening

sealant to the hub bore surface. The hub oil seal is a

“unitized” oil seal. The rolling seal lips are internal.

The rubber ribs in the bore of the seal seat onto the

spindle journal surface for static sealing. The ribs

must not be cut or damaged to avoid an oil leak path.

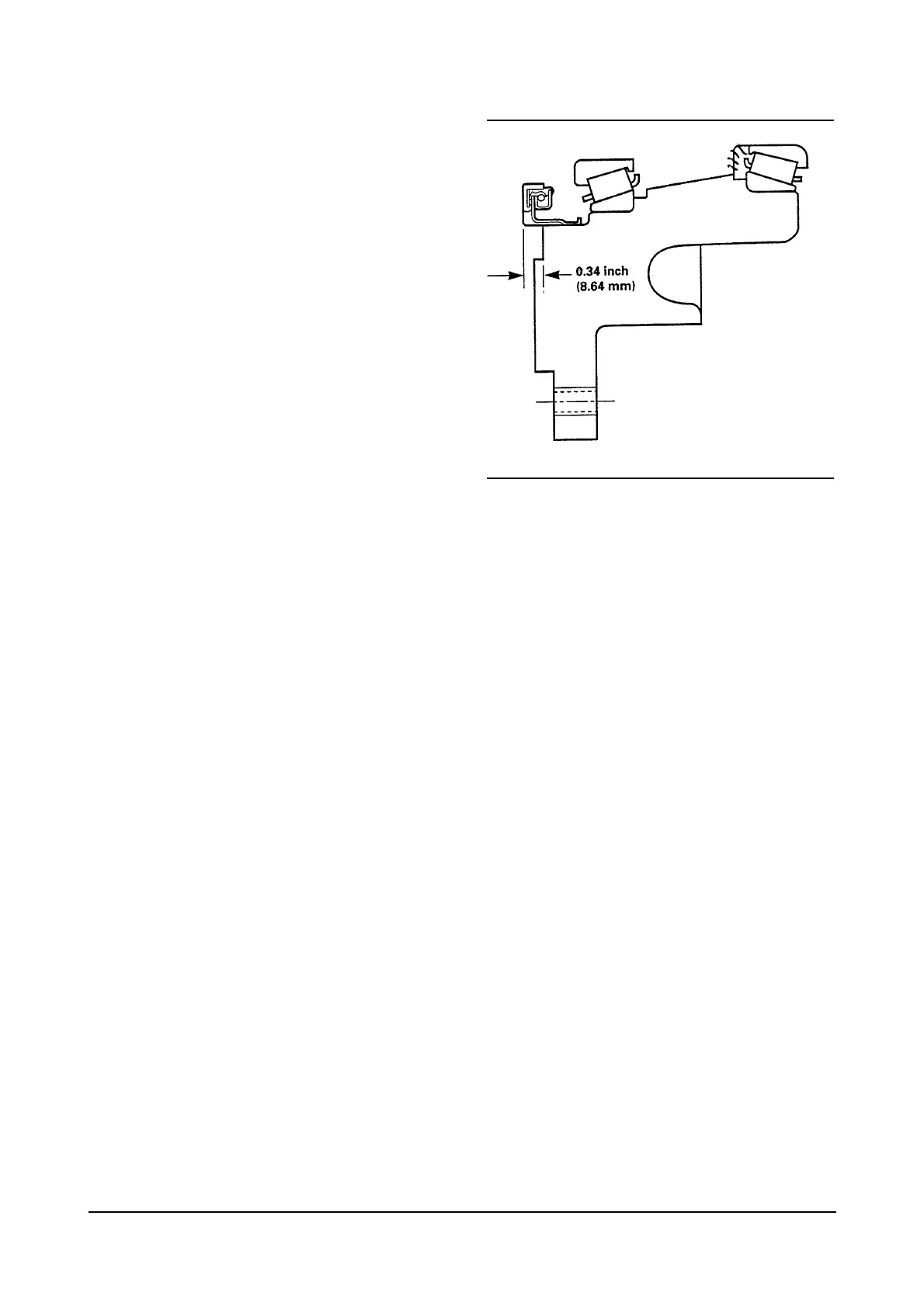

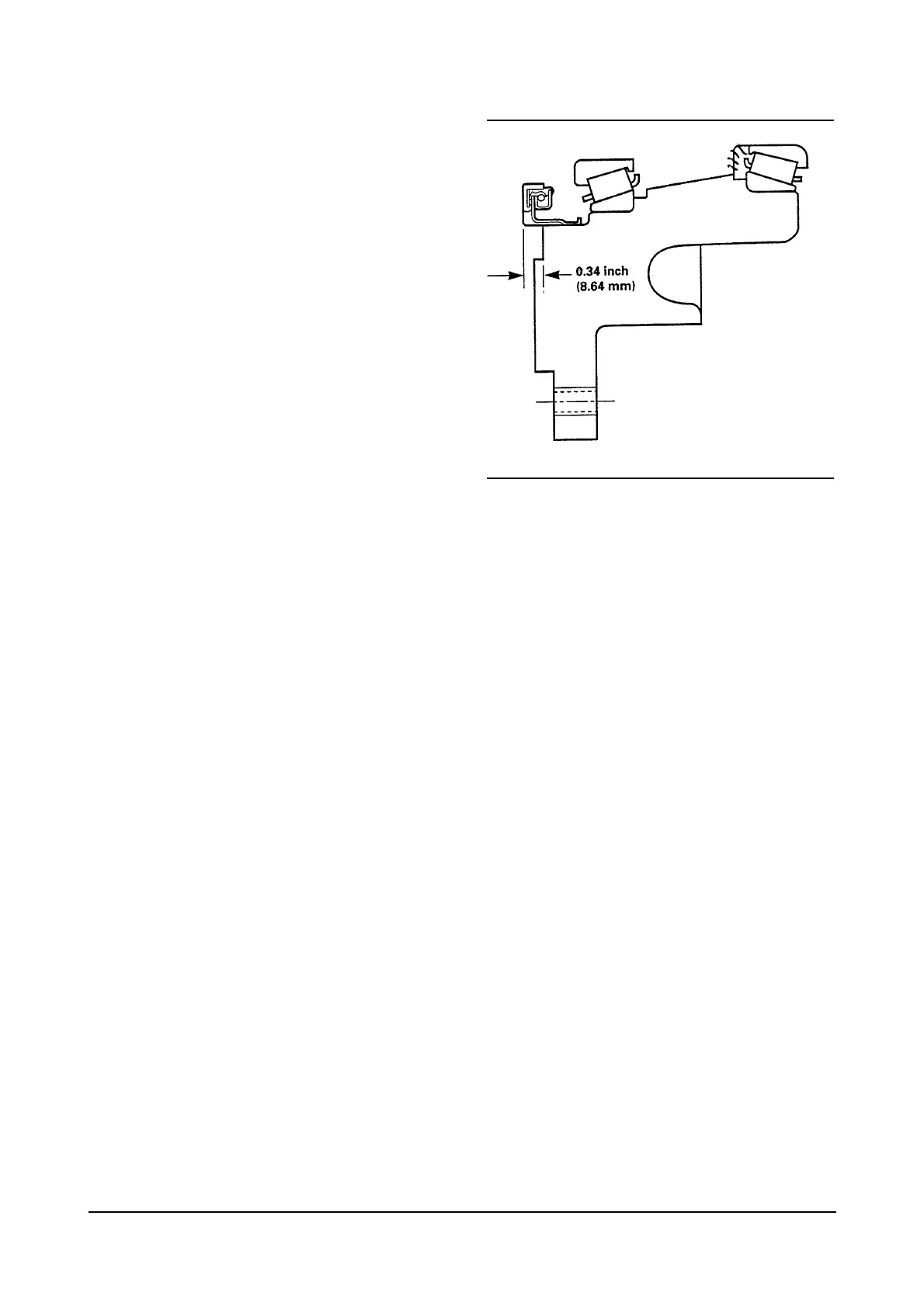

4. Use the correct oil seal driver to install the wheel

hub oil seal (29). Press the seal into the hub until

the standout from the hub machined face is 0.34

inch (8.64 mm).

5. Apply a light film of axle lubricant to the hub oil

seal (29) rubber ribs in the oil seal bore.

6. Install the wheel hub, inner bearing and oil seal

assembly onto the spindle (30). Keep the hub

assembly aligned with the spindle.

7. Apply axle lubricant to the outer bearing cone (21)

rollers. Install the outer bearing cone onto the

planetary ring gear hub (20).

8. Install the ring gear hub and bearing assembly (20,

21) onto the spindle (30).

9. Install the wheel bearing adjusting nut (16).

10. Adjust the wheel bearing preload.

58

Loading...

Loading...