DE08TS Diesel Engines Maintenance

Piston assembly

1. Disassemby of piston assembly

Disassemble piston according to the disassembly

process.

2. Piston inspection

a. Visual check

Visually check the pistons for cracks, scuff or

wear, paying particular attention to the ring

groove.

b. Clearance between the piston and cylinder

liner

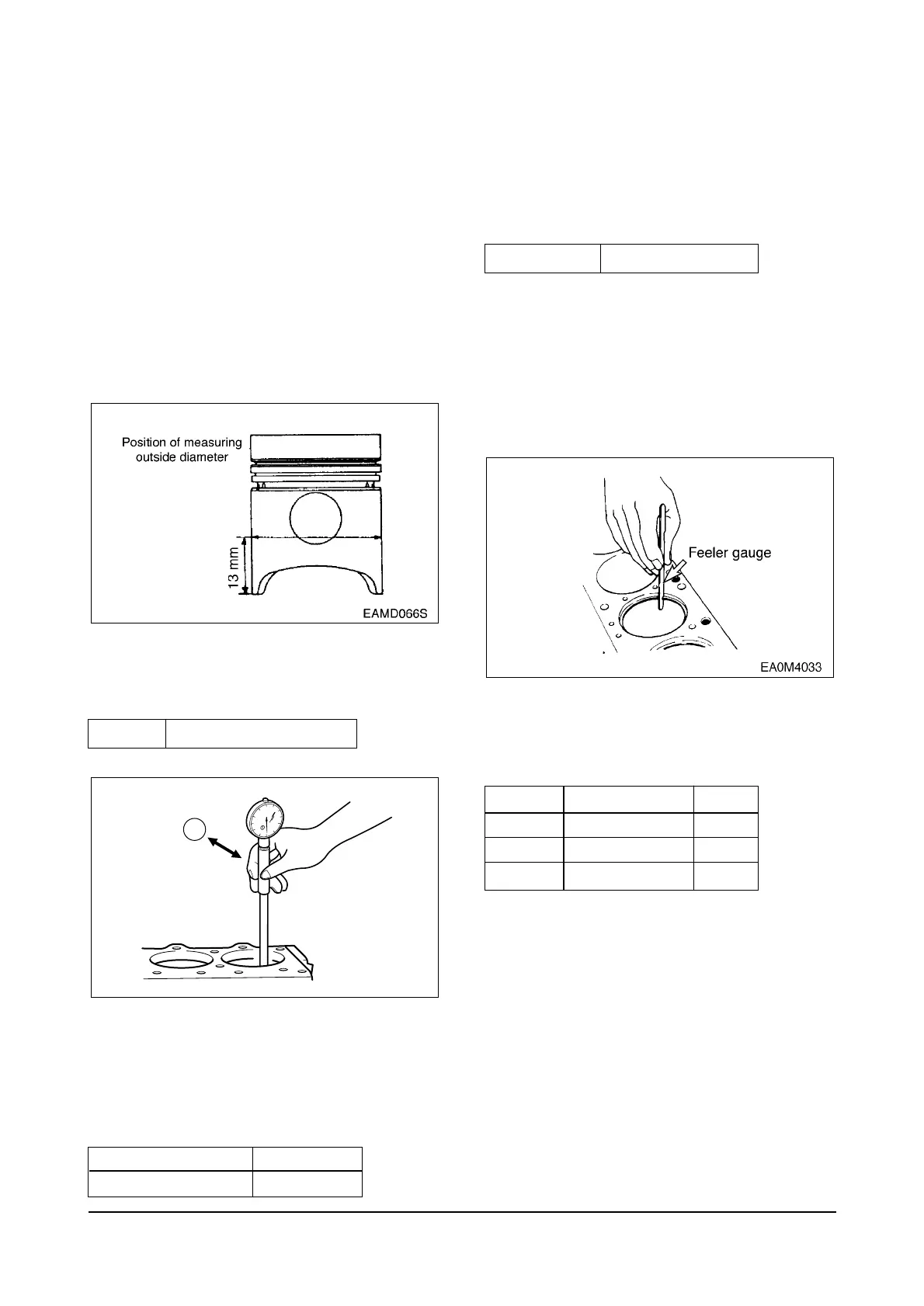

• With an outside micrometer, measure the piston

outside diameter at a point 13mm away from the

lower end of piston skirt in a direction at a right

angle to the piston pin hole.

• Using a cylinder bore gauge, measure cylinder

liner inside diameter at 3 points (cylinder top ring

contacting face, middle, and oil ring contacting

face on BDC) in a direction at an angle of 45°.

Take the mean value with the largest and small-

est values excepted.

• The clearance is computed by subtracting the pis-

ton outside diameter from the cylinder liner inside

diameter. Replace either piston or cylinder liner,

whichever damaged more, if the clearance is

beyond the specified limit.

<Clearance between piston and liner>

3. Piston rings

a. Visual check

Replace the piston rings with new ones if detected

worn or broken when the engine is overhauled.

b. Piston ring gap

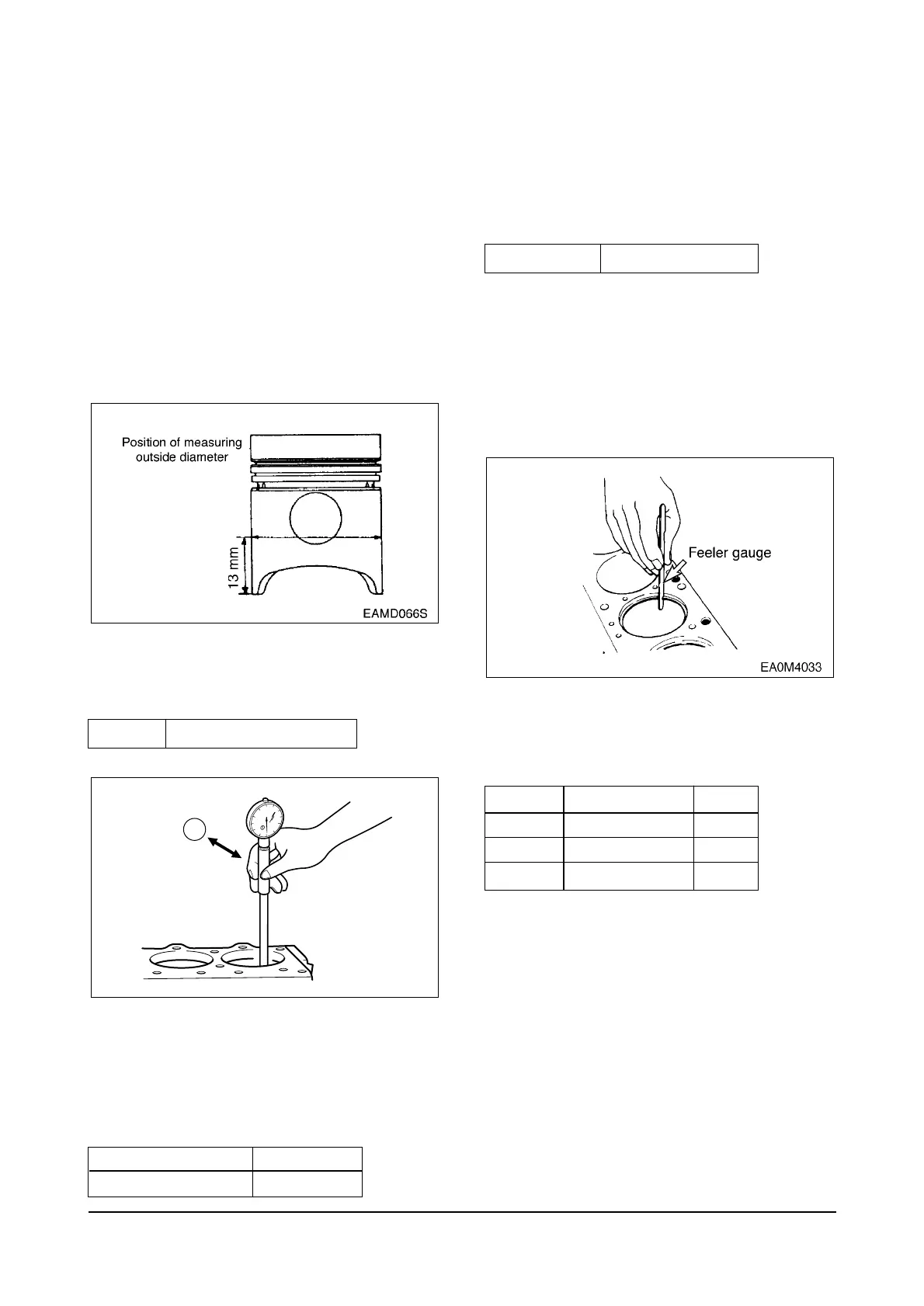

• Insert the piston ring into the upper portion of the

cylinder liner bore so that it is held at a right angle

to the cylinder liner wall.

• Measure the piston ring gap with a feeler gauge.

• Replace piston rings with new ones if the gap is

beyond the limit

2

EAMD067I

47

Standard

N

110.833 ~

N

110.897 mm

Standard Limit

N

111 ~

N

111.022 mm

N

111.122 mm

Standard 0.103~ 0.139 mm

Standard Limit

Top ring 0.40 ~ 0.60 mm 1.5 mm

2nd ring 0.40 ~ 0.60 mm 1.5 mm

Oil ring 0.30 ~ 0.50 mm 1.5 mm

Loading...

Loading...